Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finnish M39-SOV Project BUILD FINISHED

- Thread starter BasraBoy

- Start date

Re: Finnish M39-SOV Project begins....

Have you set the action screws with a torque wrench? inch/pounds but just another thing to play with and just a small change moves things around. At least it will give you a constant to work from.

Good and tight by hand can be 60 to 65 inch-pounds.

Good luck.

...MJ...

Have you set the action screws with a torque wrench? inch/pounds but just another thing to play with and just a small change moves things around. At least it will give you a constant to work from.

Good and tight by hand can be 60 to 65 inch-pounds.

Good luck.

...MJ...

Re: Finnish M39-SOV Project begins....

No, nothing too scientific yet on tigthening it down. But makes perfect sense to have known values/baseline for the action and fore-end.

Does anybody know if there any known/published values for "correct" torque on the Finnish or Russian rifles?

No, nothing too scientific yet on tigthening it down. But makes perfect sense to have known values/baseline for the action and fore-end.

Does anybody know if there any known/published values for "correct" torque on the Finnish or Russian rifles?

Re: Finnish M39-SOV Project begins....

If somebody could find any official torque values for MNs, this somebody deserves Nobel prize. What I'm saying is that it is practically impossible. You just got to use common sense.

If somebody could find any official torque values for MNs, this somebody deserves Nobel prize. What I'm saying is that it is practically impossible. You just got to use common sense.

Re: Finnish M39-SOV Project begins....

It was worth a try!

Would be happy to get an opinion on what works as a baseline.

It was worth a try!

Would be happy to get an opinion on what works as a baseline.

Re: Finnish M39-SOV Project begins....

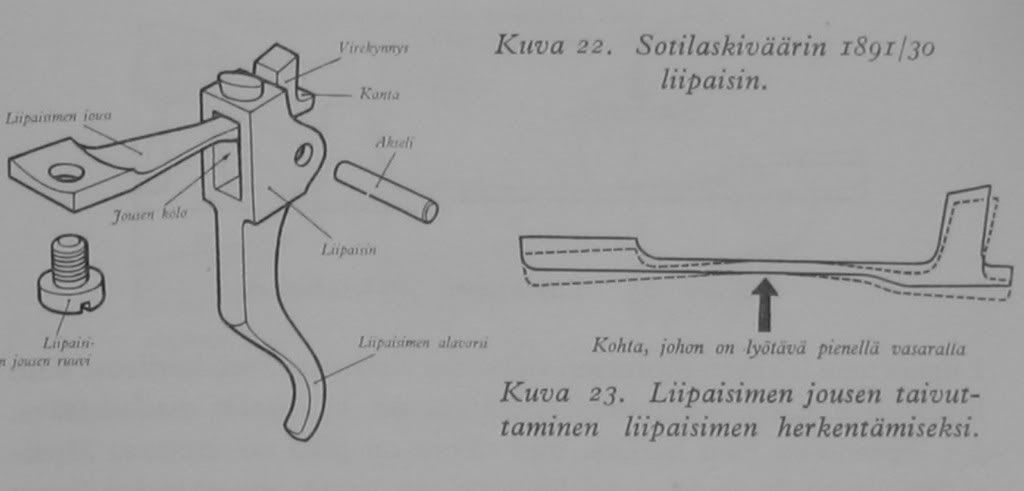

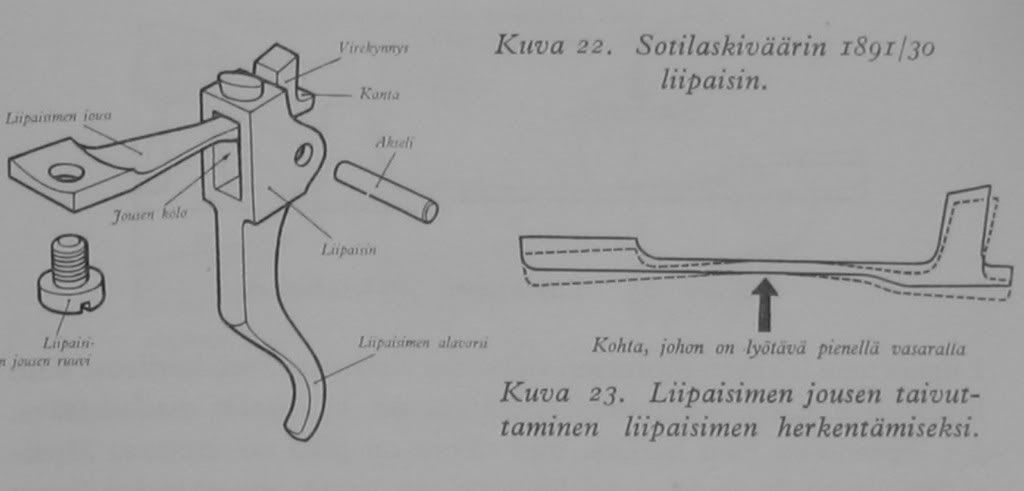

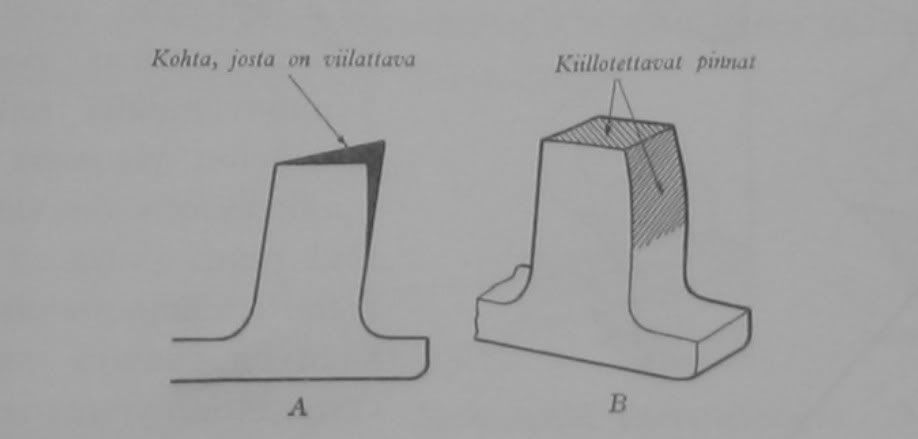

you might want to check out these- really makes a difference with trigger. M28-30 also had also unique small "safety pin" type spring for eliminating very long pre-travel. its located in trigger pin, simply giving some backwards pressure to trigger. For diy- mods, its easy to make it from...safety pin..

Also found these Finnish language instructions with google. I took these (or identical) photos years ago from certain book, and shared them in some forum.

The trigger assembly. Bend the sear as shown (tap with hammer).

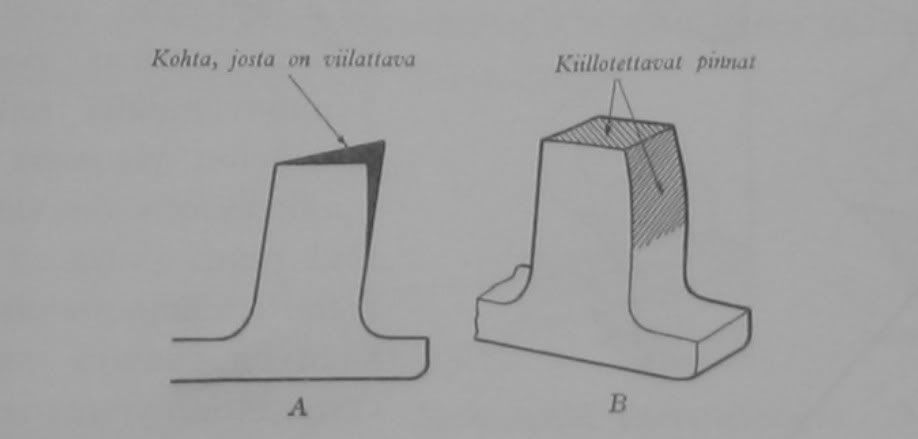

Remove metal from the shaded area (file). Polish as in pic on right.

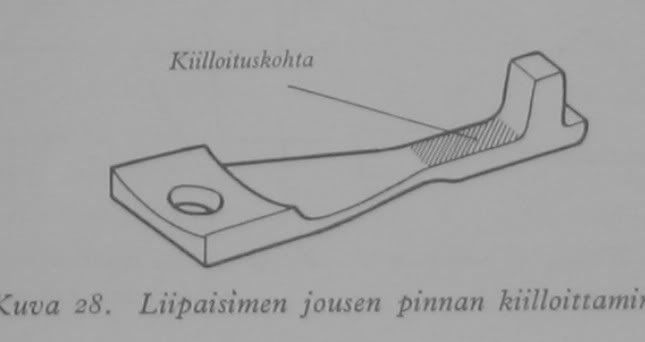

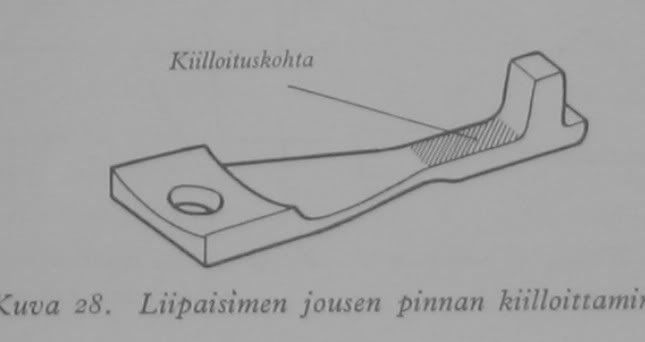

Polish the shaded area

This takes bit more effort and is not necessesary...

you might want to check out these- really makes a difference with trigger. M28-30 also had also unique small "safety pin" type spring for eliminating very long pre-travel. its located in trigger pin, simply giving some backwards pressure to trigger. For diy- mods, its easy to make it from...safety pin..

Also found these Finnish language instructions with google. I took these (or identical) photos years ago from certain book, and shared them in some forum.

The trigger assembly. Bend the sear as shown (tap with hammer).

Remove metal from the shaded area (file). Polish as in pic on right.

Polish the shaded area

This takes bit more effort and is not necessesary...

Re: Finnish M39-SOV Project begins....

JL - thanks for those diagrams. Very useful.

Would describe the trigger at the moemnt as a typical infantry rifle pull...not the worst I've ever used, but could be improved.

JL - thanks for those diagrams. Very useful.

Would describe the trigger at the moemnt as a typical infantry rifle pull...not the worst I've ever used, but could be improved.

Re: Finnish M39-SOV Project begins....

Ran into a slight problem with the project today. Got a mail from my smith:

<span style="font-style: italic">"We have test fired your rifle and it shoots OK with no case failure – please bear this in mind.

I fitted your Accumount replacement bolt shroud and head spaced your rifle today with the new gauges, see pictures above and it failed with excessive headspace (right on the edge).

I refitted the original bolt and it failed again with excessive head space.

In essence your rifle TECHNICALLY has excessive headspace. Excessive headspace means the case is being stretched and can fail, but yours doesn’t because its right on the edge.

What this means is that at the moment you can shoot the rifle but if you put it in for proof they will fail it.

What can you do?

1. You either need to find another bolt head that will head space. That means you need to find someone in the UK with a selection of spare bolt heads – could be fun.

2. I have a spare Nagant and I stripped the bolt head off this rifle and tried it in yours and it has “insufficient” head space. This means you have insufficient space for the case and the bolt will not close. However you could potentially machine the bolt face down and this bolt head would fit as we are only talking a couple of thou."</span>

It's typical of Paul to offer me a spare from his rifle but that will just move the problem on to him...which isn't my style.

Anybody got any spare Mosin bolt heads kicking around??

Ran into a slight problem with the project today. Got a mail from my smith:

<span style="font-style: italic">"We have test fired your rifle and it shoots OK with no case failure – please bear this in mind.

I fitted your Accumount replacement bolt shroud and head spaced your rifle today with the new gauges, see pictures above and it failed with excessive headspace (right on the edge).

I refitted the original bolt and it failed again with excessive head space.

In essence your rifle TECHNICALLY has excessive headspace. Excessive headspace means the case is being stretched and can fail, but yours doesn’t because its right on the edge.

What this means is that at the moment you can shoot the rifle but if you put it in for proof they will fail it.

What can you do?

1. You either need to find another bolt head that will head space. That means you need to find someone in the UK with a selection of spare bolt heads – could be fun.

2. I have a spare Nagant and I stripped the bolt head off this rifle and tried it in yours and it has “insufficient” head space. This means you have insufficient space for the case and the bolt will not close. However you could potentially machine the bolt face down and this bolt head would fit as we are only talking a couple of thou."</span>

It's typical of Paul to offer me a spare from his rifle but that will just move the problem on to him...which isn't my style.

Anybody got any spare Mosin bolt heads kicking around??

Re: Finnish M39-SOV Project begins....

If he can machine the bolt head that he has, I would go that route, if possible. If you need to get him a replacement, it would seem more likely that a random head would fit his gun before yours. No guarantee, but I think the odds would favor that route.

If he can machine the bolt head that he has, I would go that route, if possible. If you need to get him a replacement, it would seem more likely that a random head would fit his gun before yours. No guarantee, but I think the odds would favor that route.

Re: Finnish M39-SOV Project begins....

Joop, you're right.

I've spoken to Paul and he's OK with it. He'll break the rest of the gun up for spares so he'll make his money back.

The more I think about it, it is the sensible thing to do.

Joop, you're right.

I've spoken to Paul and he's OK with it. He'll break the rest of the gun up for spares so he'll make his money back.

The more I think about it, it is the sensible thing to do.

Re: Finnish M39-SOV Project begins....

STOOOOOP!

Firstly, take couple of cases and measure rim thickness.

With Lapua/Sako cases, it should be around 1.6mm. But this can vary, some say up to 1.75mm. Can't remember from top of my head.

Now, take case, Lapua for instance and use as reference for headspace measurings. Next, get shim sheet, thicknesses 0.15, 0.20, 0.25 and 0.3mm or so. Many thinner ones can be used instead, naturally.

Then cut round shims, close to same diameter with rim. Put shims between case head and bolt and try to close bolt. If bolt closes with 0.2mm shim wit reasonable amount (bit stiff) of resistance, headspace is perfectly good. If same thing happens with 0.25-0.30 shim, it's probably still safe but in very limit. Not recommended! Good or optimal would be around 0.15mm.

Don't know how your gunsmith measured it. It worst case he used gauges which measure headspace from shoulder, this is wrong. Also rim thicknesses vary, very thin rimmed gauge gives "wrong" headspace result. Measure it, or ask smith to check it for you. As you noticed, rim thickness variation between Russian (surplus?) 7.62x54R and Finnish 53R may be, in extreme case, same (or perhaps even more) than normal tight 0.1-0.15mm headspace! Therefore its well possible that gauge manufacturer has used "silly" dimensions in their gauges.

Disclaimer: all dimensions as I remember, check them from somewhere. Can measure Lapua rim when I get back home.

STOOOOOP!

Firstly, take couple of cases and measure rim thickness.

With Lapua/Sako cases, it should be around 1.6mm. But this can vary, some say up to 1.75mm. Can't remember from top of my head.

Now, take case, Lapua for instance and use as reference for headspace measurings. Next, get shim sheet, thicknesses 0.15, 0.20, 0.25 and 0.3mm or so. Many thinner ones can be used instead, naturally.

Then cut round shims, close to same diameter with rim. Put shims between case head and bolt and try to close bolt. If bolt closes with 0.2mm shim wit reasonable amount (bit stiff) of resistance, headspace is perfectly good. If same thing happens with 0.25-0.30 shim, it's probably still safe but in very limit. Not recommended! Good or optimal would be around 0.15mm.

Don't know how your gunsmith measured it. It worst case he used gauges which measure headspace from shoulder, this is wrong. Also rim thicknesses vary, very thin rimmed gauge gives "wrong" headspace result. Measure it, or ask smith to check it for you. As you noticed, rim thickness variation between Russian (surplus?) 7.62x54R and Finnish 53R may be, in extreme case, same (or perhaps even more) than normal tight 0.1-0.15mm headspace! Therefore its well possible that gauge manufacturer has used "silly" dimensions in their gauges.

Disclaimer: all dimensions as I remember, check them from somewhere. Can measure Lapua rim when I get back home.

Re: Finnish M39-SOV Project begins....

JL - thanks for the advice.

It is not the first time I've heard that using gauges for measuring MN headspace is incorrect.

However, as far as I am aware, that is how the UK proof house would determine whether they deem the rifle "safe" - whether it is "correct" as far as MN purists are concerned is not their problem.

Paul is simply trying to replicate their process prior to submitting the rifle to avoid a costly "end of the line" failure.

He has measured the gauges and the go gauge is 1.62 and the no-go gauge is 1.70mm, so therefore, if your comments are accurate, the gauges are correct

Using the replacement bolt head from the other rifle Paul has now got the M39 to pass on the gauges.

JL - thanks for the advice.

It is not the first time I've heard that using gauges for measuring MN headspace is incorrect.

However, as far as I am aware, that is how the UK proof house would determine whether they deem the rifle "safe" - whether it is "correct" as far as MN purists are concerned is not their problem.

Paul is simply trying to replicate their process prior to submitting the rifle to avoid a costly "end of the line" failure.

He has measured the gauges and the go gauge is 1.62 and the no-go gauge is 1.70mm, so therefore, if your comments are accurate, the gauges are correct

Using the replacement bolt head from the other rifle Paul has now got the M39 to pass on the gauges.

Re: Finnish M39-SOV Project begins....

Hmm.

if "no-go" gauge is 1.7mm...and Lapua/Sako/Most russian rims are very close to 1.6mm...then over 0.1mm headspace is your "gunsmiths limit" right?

I called to my own gunsmith, and verified it.

He said (verified) that target headspace hes been using is 0.1-0.15mm. But 0.2mm is ok too. 0.25+ starts to be limit, might cause some case failures.

He has built dozens if not hundred of Finnish mosins, including comp rifles, during decades.

And please dont take this as "my smith is better than yours" pissing contest.

Now, since 1.6mm rim is starting reference with most (=all) cases, it means that "oh-no" gauge would/should be 1.75 (0.15 headspace) and even 1.80mm would be still ok but close to reasonable limit.

Its one tenth difference to gauge you are using there, right?

Hmm.

if "no-go" gauge is 1.7mm...and Lapua/Sako/Most russian rims are very close to 1.6mm...then over 0.1mm headspace is your "gunsmiths limit" right?

I called to my own gunsmith, and verified it.

He said (verified) that target headspace hes been using is 0.1-0.15mm. But 0.2mm is ok too. 0.25+ starts to be limit, might cause some case failures.

He has built dozens if not hundred of Finnish mosins, including comp rifles, during decades.

And please dont take this as "my smith is better than yours" pissing contest.

Now, since 1.6mm rim is starting reference with most (=all) cases, it means that "oh-no" gauge would/should be 1.75 (0.15 headspace) and even 1.80mm would be still ok but close to reasonable limit.

Its one tenth difference to gauge you are using there, right?

Re: Finnish M39-SOV Project begins....

JL - no pissing contest implied or taken

I can quite understand that smiths in countries where MN's were issue rifles and are still prevalent may have a LOT more experience in the field than those in places where they are less common.

And I'm certainly not going to get into a discussion on tolerances and why gauge manufacturers use certain tolerances.

This is my first Mosin and is a learning experience for me.

However, what I can say is that UK proof houses are what they are - an integral part of the legal process for registering firearms for use/sale in the UK.

They charge through the nose for their "service" and their word is final.

If they use gauges of a certain tolerance then anything outside of that will fail...no chance to discuss, appeal or dispute. It's a one off deal.

So to them, whether a tenth, or thousandth or 0.25+....a fail is a fail. By how much is irrelavant.

They get paid to test - not by the pass or fail rate.

It may be that they leave a wide margin for error or are by nature risk averse. But, when it is their arses on the line legally and financially if they pass a potentially unsafe rifle, I can understand their particular point-of-view.

That's the mindset we have to contend with and the way the bar is set for compliance.

A discussion on uniform standards (or otherwise) for CIP signatory countries is not really the focus of this thread.

So provided Paul is happy that, with his 30 years of experience of the process as both a service armourer and civilian gunsmith , he has done all he can to get the rifle through proof - I'm satisfied.

JL - no pissing contest implied or taken

I can quite understand that smiths in countries where MN's were issue rifles and are still prevalent may have a LOT more experience in the field than those in places where they are less common.

And I'm certainly not going to get into a discussion on tolerances and why gauge manufacturers use certain tolerances.

This is my first Mosin and is a learning experience for me.

However, what I can say is that UK proof houses are what they are - an integral part of the legal process for registering firearms for use/sale in the UK.

They charge through the nose for their "service" and their word is final.

If they use gauges of a certain tolerance then anything outside of that will fail...no chance to discuss, appeal or dispute. It's a one off deal.

So to them, whether a tenth, or thousandth or 0.25+....a fail is a fail. By how much is irrelavant.

They get paid to test - not by the pass or fail rate.

It may be that they leave a wide margin for error or are by nature risk averse. But, when it is their arses on the line legally and financially if they pass a potentially unsafe rifle, I can understand their particular point-of-view.

That's the mindset we have to contend with and the way the bar is set for compliance.

A discussion on uniform standards (or otherwise) for CIP signatory countries is not really the focus of this thread.

So provided Paul is happy that, with his 30 years of experience of the process as both a service armourer and civilian gunsmith , he has done all he can to get the rifle through proof - I'm satisfied.

Re: Finnish M39-SOV Project begins....

This subject has always been an enormous can of worms with rimed cases and even with group marked bolt heads all #2's or #3 or X's and Z's are not equal. We have problems with this all the time and the gauges for shoulder or rim are not all the same. Unless you have a bin of bolt heads to play with and know what the inspector is using there can be problems. When I think back simpler days we would search the bins for a slightly over sized part and lap it in. Today I know a range of people who I pass the plug type go no-go's with. Thank you for the up-date and again good luck.

..MJ..

This subject has always been an enormous can of worms with rimed cases and even with group marked bolt heads all #2's or #3 or X's and Z's are not equal. We have problems with this all the time and the gauges for shoulder or rim are not all the same. Unless you have a bin of bolt heads to play with and know what the inspector is using there can be problems. When I think back simpler days we would search the bins for a slightly over sized part and lap it in. Today I know a range of people who I pass the plug type go no-go's with. Thank you for the up-date and again good luck.

..MJ..

Re: Finnish M39-SOV Project begins....

Ok BB. Just had impression that you had option to keep it as it is and shoot it- as long as its safe and properly working rifle. English is not my strongest language, something tends always to get lost..

Don't know about GB, but law here basically is that in some cases it doesn't have to be proofed unless you're not selling it. Kinda presumed that you don't like to put more effort (=money) in it unless it's necessary, thats all. Naturally proof houses do not take excuses. Here problem could be solved by registering rifle as wildcat- as long as it is safe and passes 30% overpressure test. "7.62 BasraBoy" would look cool engraved on barrel huh?

Buckets full of bolts here, but they are restricted firearm parts nowadays..

Ok BB. Just had impression that you had option to keep it as it is and shoot it- as long as its safe and properly working rifle. English is not my strongest language, something tends always to get lost..

Don't know about GB, but law here basically is that in some cases it doesn't have to be proofed unless you're not selling it. Kinda presumed that you don't like to put more effort (=money) in it unless it's necessary, thats all. Naturally proof houses do not take excuses. Here problem could be solved by registering rifle as wildcat- as long as it is safe and passes 30% overpressure test. "7.62 BasraBoy" would look cool engraved on barrel huh?

Buckets full of bolts here, but they are restricted firearm parts nowadays..

Re: Finnish M39-SOV Project begins....

MJ, JL - thanks for the further comments and support.

JL - yes, you are right. Under UK law I could keep the rifle as is and shoot it without re-proofing. If I ever wanted to sell it however (either with or without the conversion to -SOV spec) it would need to be re-proofed before selling....so not resolving it now is simply putting off the problem to another day.

And I guess being "borderline" would always be at the back of my mind every time I'm behind that bolt

As I didn't want to cut the original bolt (in case I ever did want to sell it in its original spec) I need to find a solution that headspaces correctly as ANY change to pressure bearing parts (i.e replacement of the original bolt shroud) requires re-proof.

To fail proof would mean the cost of the rifle (including getting it over from the US) would have been wastedas it would only have the option to be de-activated and become an expensive wall-hanger.

For the cost of the bolt head - which means it is now well within the tolerances of the gauges Paul has - it makes no sense NOT to have it re-proofed...lots of birds with one stone.

MJ, JL - thanks for the further comments and support.

JL - yes, you are right. Under UK law I could keep the rifle as is and shoot it without re-proofing. If I ever wanted to sell it however (either with or without the conversion to -SOV spec) it would need to be re-proofed before selling....so not resolving it now is simply putting off the problem to another day.

And I guess being "borderline" would always be at the back of my mind every time I'm behind that bolt

As I didn't want to cut the original bolt (in case I ever did want to sell it in its original spec) I need to find a solution that headspaces correctly as ANY change to pressure bearing parts (i.e replacement of the original bolt shroud) requires re-proof.

To fail proof would mean the cost of the rifle (including getting it over from the US) would have been wastedas it would only have the option to be de-activated and become an expensive wall-hanger.

For the cost of the bolt head - which means it is now well within the tolerances of the gauges Paul has - it makes no sense NOT to have it re-proofed...lots of birds with one stone.

Progress has been pretty slow since the last update...a combination of Paul's workload (seems like vintage rifles are a growing business here in the UK!) and business commitments from my side.

Project is still on-going though!!

The Accumount bolt shroud is now fitted (no problems that Paul has advised on this) with the replacement bolt head. The replacement head was a little tight so the bolt face was taken down by 2/1000th, much as per MJ1's suggestion above.

Been quite a while since I handed over the rifle to TVG....I had forgotten what a good looking rifle the M39 is!!

Latest pics I have:

Project is still on-going though!!

The Accumount bolt shroud is now fitted (no problems that Paul has advised on this) with the replacement bolt head. The replacement head was a little tight so the bolt face was taken down by 2/1000th, much as per MJ1's suggestion above.

Been quite a while since I handed over the rifle to TVG....I had forgotten what a good looking rifle the M39 is!!

Latest pics I have:

Last edited:

While wasting a day of hard rain I spent some time viewing auction sites and saw several bolt head in the $11 to $20 range. I don't want to labor over the effort your have but when I was a child we would lap the bolt-head lugs to fit the gauge not mill the face of the bolt. I would fish through my6 boxes/bins in my small portable shop till I found a slightly tight bolt. My bolts did not have removable heads so the procedure was to dye the rear of the lugs and start by stoning the high spots off before the time consuming hand lapping began. I tried to have at least one or two M14's apart on the bench to keep me off the sandbag filling details..LOL Can this not be done in your casr as the lugs are on the bolt-head and not the body/shroud?

Last edited:

MJ1, I am sure I could have done that as an alternative if I'd got stuck.

To be honest, I was just relieved that there were no issues with the Accumount part (still to resolve the scope mount sizing) and to get a bolt head that would work! Now the bolt is done and headspaces I don't feel the need to revisit it again.

Also, not too sure on the ITAR implications of shipping/importing bolt heads or other parts that might be deemed "pressure bearing" by the UK authorities without appropriate paperwork (i.e time and expense!).

But, all things being equal and within the regs, a good tip. Thanks for the input.

To be honest, I was just relieved that there were no issues with the Accumount part (still to resolve the scope mount sizing) and to get a bolt head that would work! Now the bolt is done and headspaces I don't feel the need to revisit it again.

Also, not too sure on the ITAR implications of shipping/importing bolt heads or other parts that might be deemed "pressure bearing" by the UK authorities without appropriate paperwork (i.e time and expense!).

But, all things being equal and within the regs, a good tip. Thanks for the input.

Last edited:

I have a M39 with a factory bent bolt and side mounted russian scope. I can shoot 1.5" at 100yds with the irons, but he scope wont hold a zero so it stays in the gun safe. I have been looking for a reliable scope mount. Does the Accumount that you ordered seem pretty solid?

It's not mounted yet so can't really say but physically it seems pretty good, heavy. Only problem is the fit.

Is it the mount that is the problem on your rifle or the scope that's not holding zero?

Are you looking for the hex mount or a new side mount version?

The hex mount is secured by two thumbscrews on to the dovetail of the base that screws to the receiver with three small screws either side. I only went this way because of the hex receiver. I'd imagine I will need to tighten the screws down pretty well or I expect they will slip under recoil.

I have a side rail mount on my Mauser that was prone to coming loose after a few rounds.....until I used a pair of molegrips to tighten the thumbscrews on the upper base as tight as they would reasonably go. Never been a problem since.

Maybe worth PM'ing Joop or MJ1 as they have a lot more experience of these rifles than me...this is my first Mosin.

Stay safe!

Is it the mount that is the problem on your rifle or the scope that's not holding zero?

Are you looking for the hex mount or a new side mount version?

The hex mount is secured by two thumbscrews on to the dovetail of the base that screws to the receiver with three small screws either side. I only went this way because of the hex receiver. I'd imagine I will need to tighten the screws down pretty well or I expect they will slip under recoil.

I have a side rail mount on my Mauser that was prone to coming loose after a few rounds.....until I used a pair of molegrips to tighten the thumbscrews on the upper base as tight as they would reasonably go. Never been a problem since.

Maybe worth PM'ing Joop or MJ1 as they have a lot more experience of these rifles than me...this is my first Mosin.

Stay safe!

The mount/scope seem rock solid on the side of the rifle. It is attached via a swing lever mount that once it is attached i can't get it to wiggle at all. I really think that is the scope. It is the old Russian scope that you can put a AA battery(or AAA, I can't remember) in and had the illuminated reticle, but it no longer works. I'll send a PM to Joop or MJ1 when I get back from my deployment. Right now I don't have access to the rifle to do any trouble shooting so I hate to bother anyone if I can't put my hands on the rifle to answer questions. I am really trying to do some research to find a mount that does not ad hole to the receiver to mount onto the rifle when I get home. It is in amazing condition and is a matching numbers weapon so I am trying to not detract from the value and only add to the fun/accuracy of the rifle.

If the mount is soild, I'd not mess with it. Maybe it is something inside the scope?

Maybe the other guys can give you some advice on guys in the US who are good with Russian scopes who may be able to check it out before you start removing/changing/adding anything?

Maybe the other guys can give you some advice on guys in the US who are good with Russian scopes who may be able to check it out before you start removing/changing/adding anything?

Another splendid build underway I see.

I must say your treads are quite inspirational. Keep up the good work, would say best of luck but due to the amount of work you puzzle your rifles together with I think its more the fruits of hard labour and love.

Cheers from Norway.

I must say your treads are quite inspirational. Keep up the good work, would say best of luck but due to the amount of work you puzzle your rifles together with I think its more the fruits of hard labour and love.

Cheers from Norway.

Firstly,.....I've got to start with an apology....it's been a while since I updated this thread. Two main reasons, Paul's workload and his machinist falling ill meant the final parts of the project took a while. In addition, normal life took over and I simply haven't been around too much to follow up and post news.

Anyway.....cut a long story short, it's all come together without any dramas - even the Accumount scope mount was a breeze in the end with minimal lapping required.

Have just got first pics of the finished article, quite literally hot from Paul's bench to the pics this afternoon:

We're going out tomorrow to shoot/final test/zero the rifle and I'll be back with an update (and more pics) in a couple of days.

From what I can see so far...looking good to me!

Anyway.....cut a long story short, it's all come together without any dramas - even the Accumount scope mount was a breeze in the end with minimal lapping required.

Have just got first pics of the finished article, quite literally hot from Paul's bench to the pics this afternoon:

We're going out tomorrow to shoot/final test/zero the rifle and I'll be back with an update (and more pics) in a couple of days.

From what I can see so far...looking good to me!

Last edited:

That looks gorgeous!

If I could make one suggestion; you may want to move the scope back in the mount so that the front ring is in front of the recoil ring on the tube. It may be fine without doing this (and I know eye relief is an issue for some by doing it this way) but that's the way they were designed.

Anxious to see how she shoots!

John

If I could make one suggestion; you may want to move the scope back in the mount so that the front ring is in front of the recoil ring on the tube. It may be fine without doing this (and I know eye relief is an issue for some by doing it this way) but that's the way they were designed.

Anxious to see how she shoots!

John

Joop - thanks!

Yes, I notice that on the scope, easily fixed. But ran into some other problems on first run out....

We need to look at the alignment of the scope to the bore. We ran out of adjustment and , even with the elevation topped out at the top of the scope I was still having to hold over at the top of a 300yd NRA target to hit centre at that distance. It seems Paul's machinist may have shimmed the front of the hex mount to get correct alignment to the bore - back to the bench on this.

Also the performance was wildy inconsistent. Shot around 20 rounds between myself and paul today. It was all over the place (using D166 Lapua) - think once we sort out the scope/mount we'll need to play with the front barrel band to get the accuracy back.

Paul was also not too happy with the relief cut he made to fit the hex mount and wants to open it out a bit so there is no danger of spiting the stock if the action moves under recoil.

On the upside there was a noticable difference from the extra weight in the M39 over Paul's '42 91/30 - far kinder on the shoulder!

All being well, should get to have another go next weekend.

Yes, I notice that on the scope, easily fixed. But ran into some other problems on first run out....

We need to look at the alignment of the scope to the bore. We ran out of adjustment and , even with the elevation topped out at the top of the scope I was still having to hold over at the top of a 300yd NRA target to hit centre at that distance. It seems Paul's machinist may have shimmed the front of the hex mount to get correct alignment to the bore - back to the bench on this.

Also the performance was wildy inconsistent. Shot around 20 rounds between myself and paul today. It was all over the place (using D166 Lapua) - think once we sort out the scope/mount we'll need to play with the front barrel band to get the accuracy back.

Paul was also not too happy with the relief cut he made to fit the hex mount and wants to open it out a bit so there is no danger of spiting the stock if the action moves under recoil.

On the upside there was a noticable difference from the extra weight in the M39 over Paul's '42 91/30 - far kinder on the shoulder!

All being well, should get to have another go next weekend.

Last edited:

Joop - thanks!

Yes, I notice that on the scope, easily fixed. But ran into some other problems on first run out....

But, we need to look at the alignment of the scope to the bore. We ran out of adjustment and , even with the elevation topped out at the top of the scope I was still having to hold over at the top of a 300yd NRA target to hit centre at theat distance. It seems Paul's machinist may have shimmed the front of the hex mount to get correct alignment to the bore - back to the bench on this.

Also the performance was wildy inconsistent. Shot around 20 rounds between myself and paul today. It was all over the place (using D166 Lapua) - think once we sort out the scope/mount we'll need to play with the front barrel band to get the accuracy back.

Paul was also not too happy with the relief cut he made to fit the hex mount and wants to open it out a bit so there is no danger of spiting the stock if the action moves under recoil.

On the upside there was a noticable difference from the extra weight in the M39 over Paul's '42 91/30 - far kinder on the shoulder!

All being well, should get to have another go next weekend.

You probably already know what to try, but I would shoot it w/o the scope from sand bag at 50 m - see if it's still all over the place. If 50 m group is decent, say, 1.3-1.5" inches, then something is probably wrong with the scope setup. If group is much bigger, it's either, I think, "bad" barrel or something is loose or getting loose in the process, like action screws, or front band.... Also, from my experience, MN barrel is getting hot relatively quick, after 5-6 shots, so heat related distortion of rifle parts may be a factor affecting accuracy/consistency in rapid fire mode. Also, it's always a good idea to make sure that whatever is left from the original muzzle crown is usable, means it is still concentric to the bore right near the edge of the bore.... Good luck.

Last edited:

Basra,

WTF,that's a Finn: from the avg.e donor M-N it should have inherited the action only, and even the same action, arsenal T.L.C.'ed, at his time.. at 50 mts, from bags & IRONS ONLY,this Finn should be a one-holer or little worse_

Keep the faith !

WTF,that's a Finn: from the avg.e donor M-N it should have inherited the action only, and even the same action, arsenal T.L.C.'ed, at his time.. at 50 mts, from bags & IRONS ONLY,this Finn should be a one-holer or little worse_

Keep the faith !

Last edited:

Kortik, thanks or the input, yes we will get it out again this next weekend and shoot without the scope, see if we can't get it back to where it was as posted before. Paul used a new machinist on this project...maybe he is not quite as good as Bob, his old one.

Good news is Bob has now recovered from his health issue....so all is not lost if the new guy has done something he shouldn't!!

wilecoyote..."the force is strong in this one!" I'm not giving up!!

Good news is Bob has now recovered from his health issue....so all is not lost if the new guy has done something he shouldn't!!

wilecoyote..."the force is strong in this one!" I'm not giving up!!

BB,

I had an SOV clone done once and ran into this exact same issue. I just put a small brass shim in the front ring, under the scope and all was well again. However, I will also add that that arc of the Lapua D166 is a strange one, as I was to find out later. This will obviously play a big part in all of this. I found that, even at 200m, the bullet could still moving upwards in it's arc, depending on the velocity of the load. I would have to check my notes to see how much more specific I can be on this issue, but I think you get the idea. If you can shim the mount in a different manner to compensate, that's optimum. If you reach the end of that road and still need to bring the scope up, look into shimming under the scope in the front ring.

Cheers!

John

I had an SOV clone done once and ran into this exact same issue. I just put a small brass shim in the front ring, under the scope and all was well again. However, I will also add that that arc of the Lapua D166 is a strange one, as I was to find out later. This will obviously play a big part in all of this. I found that, even at 200m, the bullet could still moving upwards in it's arc, depending on the velocity of the load. I would have to check my notes to see how much more specific I can be on this issue, but I think you get the idea. If you can shim the mount in a different manner to compensate, that's optimum. If you reach the end of that road and still need to bring the scope up, look into shimming under the scope in the front ring.

Cheers!

John

Thanks Joop

Paul checked his records and his original test groups with irons were with a .303 bullet. I'll take both along at the weekend.

On the shim, we have already put a shim at the front of the mount to align the scope with the bore. Maybe we now need to place an additional shim the length of the mount or receiver to get the scope adjustment back?

Paul checked his records and his original test groups with irons were with a .303 bullet. I'll take both along at the weekend.

On the shim, we have already put a shim at the front of the mount to align the scope with the bore. Maybe we now need to place an additional shim the length of the mount or receiver to get the scope adjustment back?

BasraBoy

Great work, the rifle looks awesome. I hope you are done with all necessary adjustments; it is sometimes a long process, including frustrating moments (sometimes not) but once done, there are no regrets. I am sure all of this sounds familiar to you, as I read few of your posts. Got a couple of Russian Mosin-Nagant, including a '43 Tula sniper PU. It took time, efforts and scratching head moments but now I can take it anytime at the range and it performs as it should. This rifle has convinced more than one shooter to look into the "Mosin side of things"; few month ago, I let a shooter friend of mine try it for a few shots (with reloads), before you knew it, he was making head shots at 550 yards, another converted one.

Congrats on a beautiful project

Great work, the rifle looks awesome. I hope you are done with all necessary adjustments; it is sometimes a long process, including frustrating moments (sometimes not) but once done, there are no regrets. I am sure all of this sounds familiar to you, as I read few of your posts. Got a couple of Russian Mosin-Nagant, including a '43 Tula sniper PU. It took time, efforts and scratching head moments but now I can take it anytime at the range and it performs as it should. This rifle has convinced more than one shooter to look into the "Mosin side of things"; few month ago, I let a shooter friend of mine try it for a few shots (with reloads), before you knew it, he was making head shots at 550 yards, another converted one.

Congrats on a beautiful project

ON - thanks for the kind words and encouragement. Appreciated.

We are still going through the fiddling process!

Working on finding the right ammo.....the batch of D166 I bought seems a little under powered so is not really giving us consistent performance to work with. The batch of 174gr .311 SMK I have seemed to suit the rifle better, but also going to try some 180gr S&B as this is what Paul ran on the initial accuracy test above.

Also, the mount was fitted by a temporary machinist as Paul's regular guy was sick - we both have concerns that the bloke has not really ensured that he aligned everything vertically and horizontaly to the bore so, now Bob is back, we're going to get him to look at it. Scope appears to be sitting diagonally across the bore with the objective out to the left of the centre line at the moment....could be a few things but we suspect the base is not squared to the receiver or the mount is not squared to the base.

Seems the temporary guy was a modern target rifle "specialist" so was outside his comfort zone on the Mosin (good at putting together close tolerance modern parts, but a bit lost wth 70-120year old parts)....but, that being said, he should have checked the basics rather than just slapping the mount on the receiver and hoping!! Paul called him out on his work and his response was that he doesn't understand why people bother with these old guns. He offered to have another go...we declined his kindness

But Bob is sure we can get it right....just a bit more time and fiddling than expected.

We are still going through the fiddling process!

Working on finding the right ammo.....the batch of D166 I bought seems a little under powered so is not really giving us consistent performance to work with. The batch of 174gr .311 SMK I have seemed to suit the rifle better, but also going to try some 180gr S&B as this is what Paul ran on the initial accuracy test above.

Also, the mount was fitted by a temporary machinist as Paul's regular guy was sick - we both have concerns that the bloke has not really ensured that he aligned everything vertically and horizontaly to the bore so, now Bob is back, we're going to get him to look at it. Scope appears to be sitting diagonally across the bore with the objective out to the left of the centre line at the moment....could be a few things but we suspect the base is not squared to the receiver or the mount is not squared to the base.

Seems the temporary guy was a modern target rifle "specialist" so was outside his comfort zone on the Mosin (good at putting together close tolerance modern parts, but a bit lost wth 70-120year old parts)....but, that being said, he should have checked the basics rather than just slapping the mount on the receiver and hoping!! Paul called him out on his work and his response was that he doesn't understand why people bother with these old guns. He offered to have another go...we declined his kindness

But Bob is sure we can get it right....just a bit more time and fiddling than expected.

Last edited:

What a great thread! Love seeing the Finn getting the royal treatment. As a Mosin collector of many years, I mainly just take them out and shoot them. Interesting approach, this whole "restoring" deal. I greatly appreciate the work and detail put into your rifle.

I will be thinking of your gun while I'm shooting my 1932 91/30 this saturday in California.

I will be thinking of your gun while I'm shooting my 1932 91/30 this saturday in California.

Thanks Scott.

Sadly my job has just been "reallocated" to someone in China so all my projects are on hold until I can get back on the ladder!!

Sadly my job has just been "reallocated" to someone in China so all my projects are on hold until I can get back on the ladder!!

Very sorry to hear that, BB. I hope things turn around for you, soon. Hang in there.Thanks Scott.

Sadly my job has just been "reallocated" to someone in China so all my projects are on hold until I can get back on the ladder!!

Any updates Mr. Basra? I love your project threads btw. This ones definitely gone be a shooter when youre done.

BTW, I believe I remember seeing a Mauser sniper in one of your pics... Would that be the ZF39 or 41? Not trying to derail but how does the Mauser shoot? Those Mausers, especially the German and Swede snipers, always seem to me the most interesting old service rifles. Also, out of all the old service/sniper rifles you have, which has been your favorite and/or best shooting so far?

One more thing, youre from Britain, andddd you have an Enfield(s), are you capable of the "mad minute"? I always thought that was the coolest thing seeing people shooting those Enfields like theyre semi-auto. And I see some people claiming the "mad minute" is a myth, whats your take on this?

Thank you sir.

Blake.

BTW, I believe I remember seeing a Mauser sniper in one of your pics... Would that be the ZF39 or 41? Not trying to derail but how does the Mauser shoot? Those Mausers, especially the German and Swede snipers, always seem to me the most interesting old service rifles. Also, out of all the old service/sniper rifles you have, which has been your favorite and/or best shooting so far?

One more thing, youre from Britain, andddd you have an Enfield(s), are you capable of the "mad minute"? I always thought that was the coolest thing seeing people shooting those Enfields like theyre semi-auto. And I see some people claiming the "mad minute" is a myth, whats your take on this?

Thank you sir.

Blake.

Last edited:

Thanks Scott.

Sadly my job has just been "reallocated" to someone in China so all my projects are on hold until I can get back on the ladder!!

You can come work in Idaho...We need people like you. You might even get a shot at one or two of that collection of James Bonds that got sold to "some collector or other"

Hello lads! Have got a bit of contract work that will take me through to mid February- only problem is it's a two hour drive from the house so don't have a lot of time in the week to do much other than drive, work, eat, sleep!!

Makes those 7 weeks of "resting" before I secured it - walking the dogs, bit of shooting, no stress-disturbed nights - seem like heaven!! Will keep trying on the lotto!!

Will keep trying on the lotto!!

JB/Sand - no updates at the moment but the Mosin is on Paul's list to get in the shop but he has (as always) a ton of work to get through before that happens.

Will keep you all updated as it happens.

In the meantime (a bit early) wish everyone on the Hide all the best for Christmas and the New Year! Hope it is a good one for everyone!

PS..Sand...Idaho?...would love to, mate!! Hook me up!!?

Makes those 7 weeks of "resting" before I secured it - walking the dogs, bit of shooting, no stress-disturbed nights - seem like heaven!!

JB/Sand - no updates at the moment but the Mosin is on Paul's list to get in the shop but he has (as always) a ton of work to get through before that happens.

Will keep you all updated as it happens.

In the meantime (a bit early) wish everyone on the Hide all the best for Christmas and the New Year! Hope it is a good one for everyone!

PS..Sand...Idaho?...would love to, mate!! Hook me up!!?

Last edited:

After a (too) long layoff from the range......finally got to shoot the Mosin again last week.

The good news is I was getting 1" groups over iron sights at 100yds with factory PP and HPS house 7.62x54R.

The bad news is that it seems 100% certain that the problems we were having before is down to the PEM scope's internals......so it's off to Paul's go-to scope guy to see if it is fixable.

Must say, the old Finn was great to shoot - much more so than Paul's Russian version - that extra weight certainly makes it less tiring on the recoil!

The good news is I was getting 1" groups over iron sights at 100yds with factory PP and HPS house 7.62x54R.

The bad news is that it seems 100% certain that the problems we were having before is down to the PEM scope's internals......so it's off to Paul's go-to scope guy to see if it is fixable.

Must say, the old Finn was great to shoot - much more so than Paul's Russian version - that extra weight certainly makes it less tiring on the recoil!

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 14

- Views

- 1K

- Replies

- 13

- Views

- 1K

- Replies

- 1

- Views

- 752