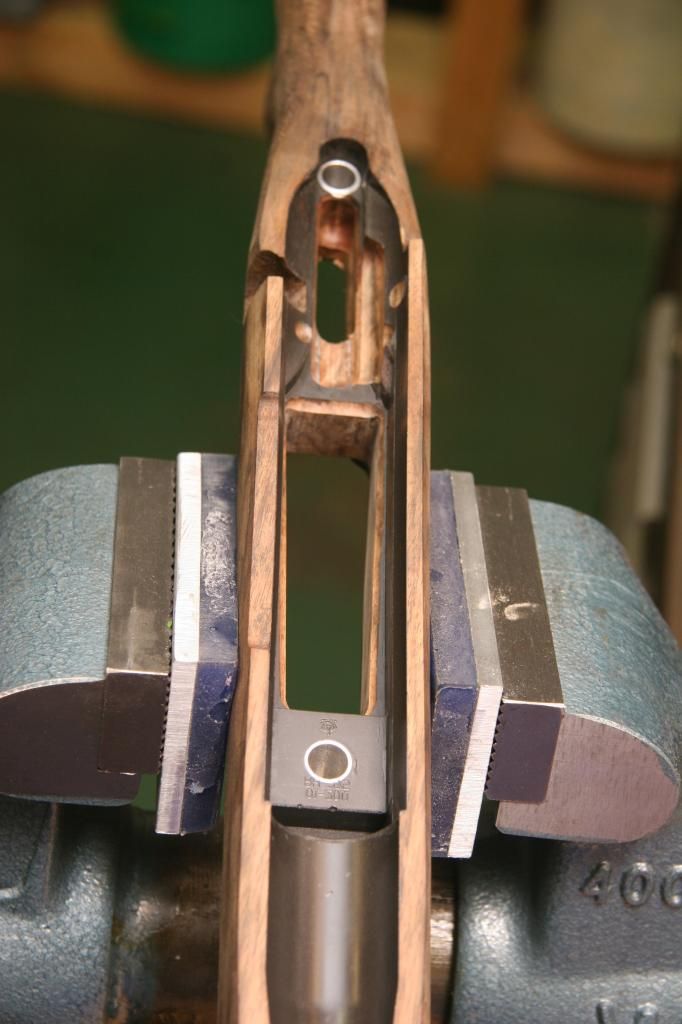

I have recently received my A4 McMillan to put my Rem700 in. Just curious as to who to send it to to get bedded. I have an APA bottom RTG, so I was thinking of just sending the barreled action, stock, and bottom metal to the guys at APA to get the rifle assembled and bedded. (If anyones had a bedding job done by APA chime in with your results.)

Anyways.....back to the real question....Id like to know if I ought to have my stock glass bedded, pillar bedded, or glass AND pillar bedded, and why you choose the method you choose. Thanks.

Anyways.....back to the real question....Id like to know if I ought to have my stock glass bedded, pillar bedded, or glass AND pillar bedded, and why you choose the method you choose. Thanks.