Re: bore curvature

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: M.Gordon</div><div class="ubbcode-body">I understand why you would want the neck area dialed in, but how would you be dialing in the just the neck area?</div></div>

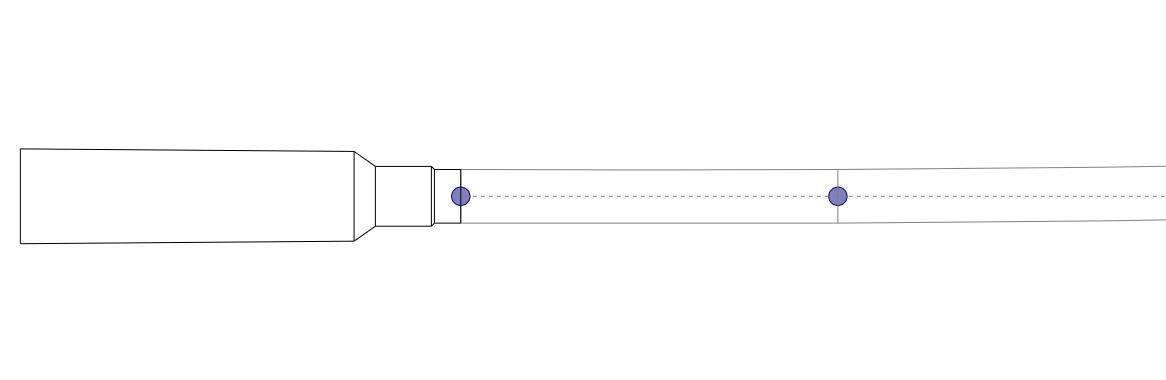

You would dial it in by positioning the indicator on the neck area.

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">What benefit would it be to have the muzzle dialed in while you are doing work on the chamber?</div></div>

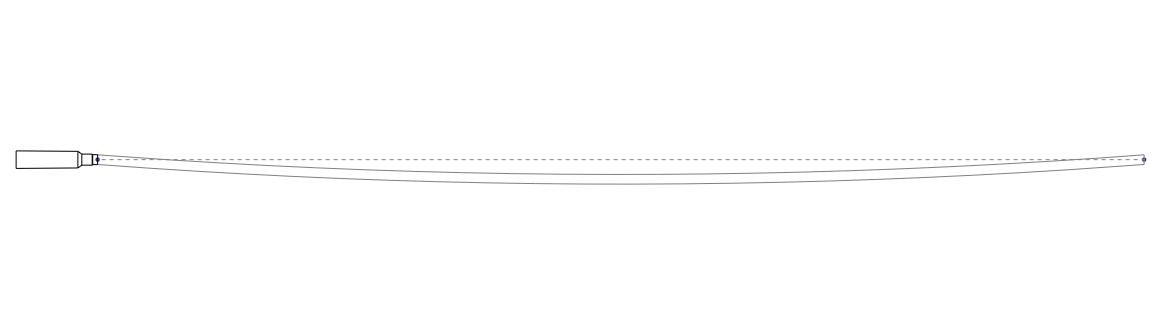

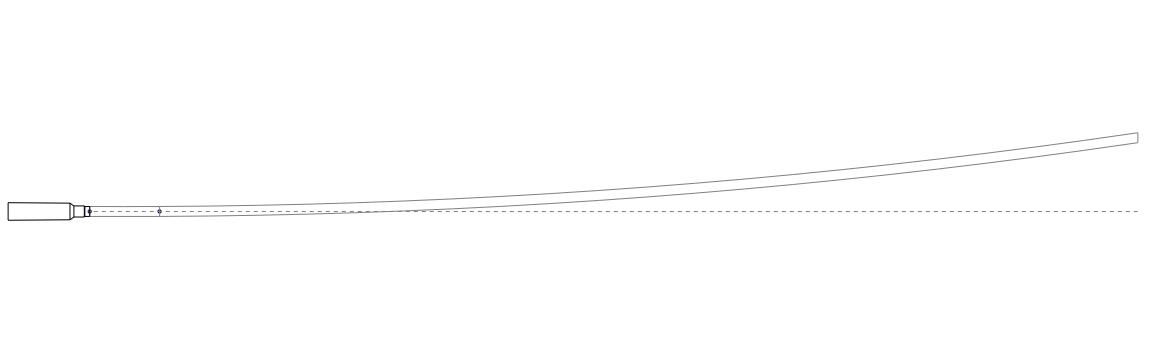

It would allow the bore to be aligned with the chamber. I consider the bore to be the whole bore not just a 3 inch long section at one end of the barrel.

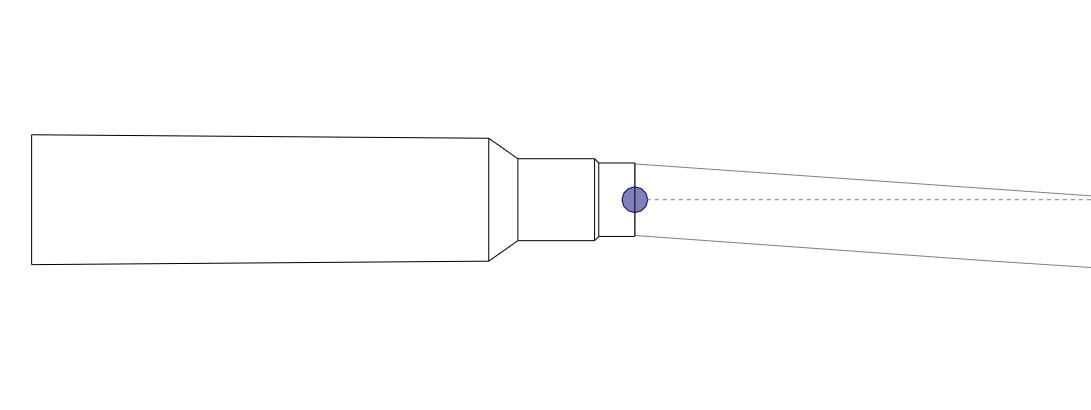

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">If you take fixtures like the True Bore Alignment system from Straight Shot Gunsmithing

True Bore Alignment System and dial a barrel in, co-axially at two separate points in the chamber area, I guarantee you will find similar results as to what I am showing with the barrel having a curvature to the bore.</div></div>

Exactly, that is why I said I didn't think it should be done that way.

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">So with this being said why would you concern your self with the muzzle when you are doing all of your work on the chamber end?</div></div>

So the muzzle will be aligned with the chamber.

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">I know its been an older and well accepted practice to place ground pins in the muzzle and on the chamber end, then dial in .001", but that approach does not give me as straight of a chamber as what I'm getting right now.</div></div>

I don't see what this has to do with chamber straightness. Why can't the chamber be straight regardless of bore alignment. Maybe chamber straightness needs to be defined also.

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body"> By dialing a chamber in the way you are describing will also promote a larger diameter chamber than the way I am dialing.</div></div>

Why would it make a difference in the diameter of the chamber?

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">Different strokes for different folks, I know there have been many accurate rifles built doing the pin in the muzzle method, however I feel its just not as good of a chambering job than a timed curvature co-axially indicated bore.</div></div>

Why would it not be as good of a job if it resulted in less runout of the muzzle bore ? Seems like it would be a better job.