Rifle: Rem700 PSS .308

Reloading brass from this rifle.

Using a Whidden FL die, it's a modified die that doesn't cram the brass back to starting size like some FL dies, but does a 'moderate FL resize.

Directions say to use a shoulder bump gauge to set the shoulder back about.002-.003 if reusing brass fired in that rifle.

My 'pickle': 1 FC match .308 cartridge case 1x fired.

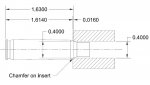

Bump gauge shows 1.612 so it would seem to set the die so the shoulder bumps back .002-.003. ie 1.609-1.610.

The shoulder diameter just below the shoulder shows .455.

Does that sound right?

Next have about 150 .308 FC match cases fired from a different .308 Rem 700 measured with the shoulder bump gauge showing 1.620. Apparently a little different chamber than mine.

When I FL re size these cases (did 4 so far) am showing 1.586 on the shoulder bump gauge. The case diameter after FL resize shows .451/.452

Does that sound right?

Am I nitpicking? Should I just FL resize all the cases from the other rifle, trim to 2.005 (suggestion was 2.007) and start loading, shooting and then using the shoulder bump gauge to set the dies so it gives a .002/.003 shoulder setback?

Die set: Whidden FL resize, Forster Micro seating die.

HAve all the primer pocket reamer, deburring tools, neck chamfer, etc to work from.

Was decent at this 25 years ago - relearning - but never ran into the 'bump gauge' use before this.

Thanks very much for any help - or reference to other threads..... did a search and found lots of things to read, but stuck on this issue.

Wayne

Reloading brass from this rifle.

Using a Whidden FL die, it's a modified die that doesn't cram the brass back to starting size like some FL dies, but does a 'moderate FL resize.

Directions say to use a shoulder bump gauge to set the shoulder back about.002-.003 if reusing brass fired in that rifle.

My 'pickle': 1 FC match .308 cartridge case 1x fired.

Bump gauge shows 1.612 so it would seem to set the die so the shoulder bumps back .002-.003. ie 1.609-1.610.

The shoulder diameter just below the shoulder shows .455.

Does that sound right?

Next have about 150 .308 FC match cases fired from a different .308 Rem 700 measured with the shoulder bump gauge showing 1.620. Apparently a little different chamber than mine.

When I FL re size these cases (did 4 so far) am showing 1.586 on the shoulder bump gauge. The case diameter after FL resize shows .451/.452

Does that sound right?

Am I nitpicking? Should I just FL resize all the cases from the other rifle, trim to 2.005 (suggestion was 2.007) and start loading, shooting and then using the shoulder bump gauge to set the dies so it gives a .002/.003 shoulder setback?

Die set: Whidden FL resize, Forster Micro seating die.

HAve all the primer pocket reamer, deburring tools, neck chamfer, etc to work from.

Was decent at this 25 years ago - relearning - but never ran into the 'bump gauge' use before this.

Thanks very much for any help - or reference to other threads..... did a search and found lots of things to read, but stuck on this issue.

Wayne