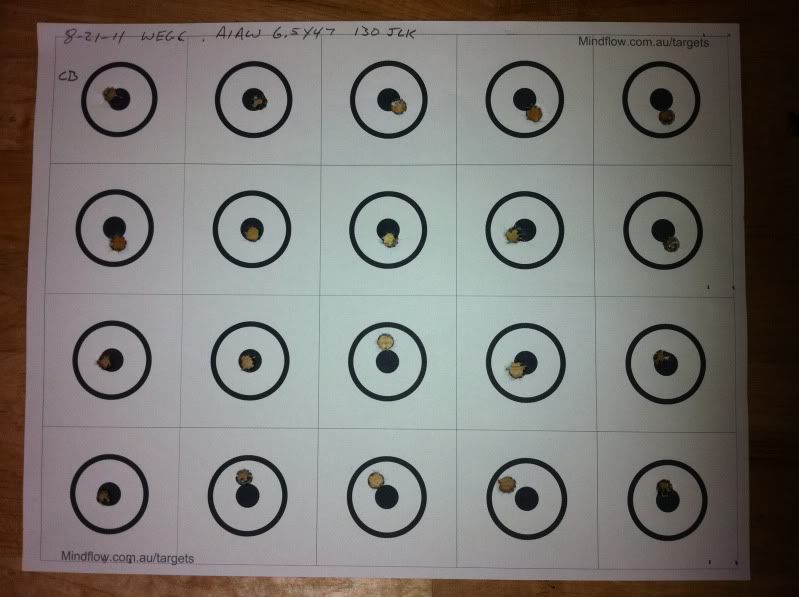

I shoot a Remington 700 .260 with a Criterion 28 inch pre-fit bull barrel, 1:8 twist.

I am using 140 grain A-Max and 142 grain Sierra Match Kings to develop the correct load.

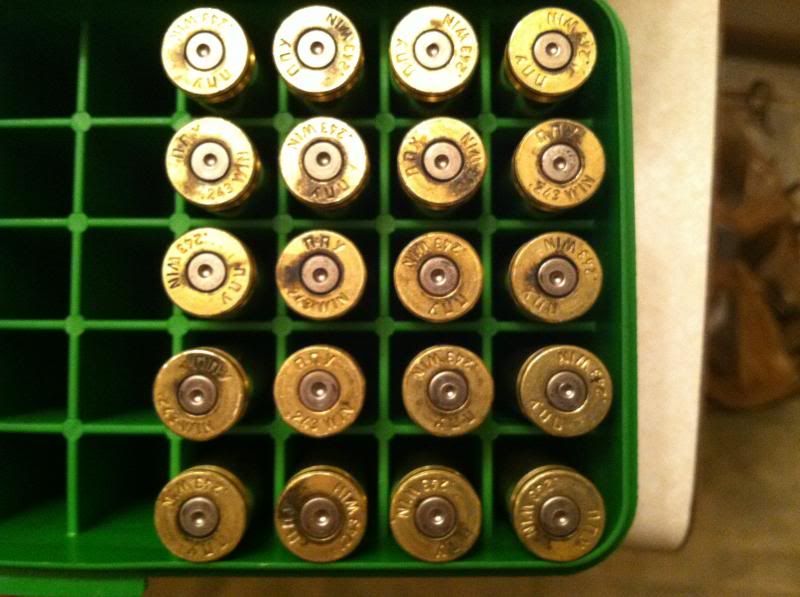

Prvi .243 brass, Tula primers

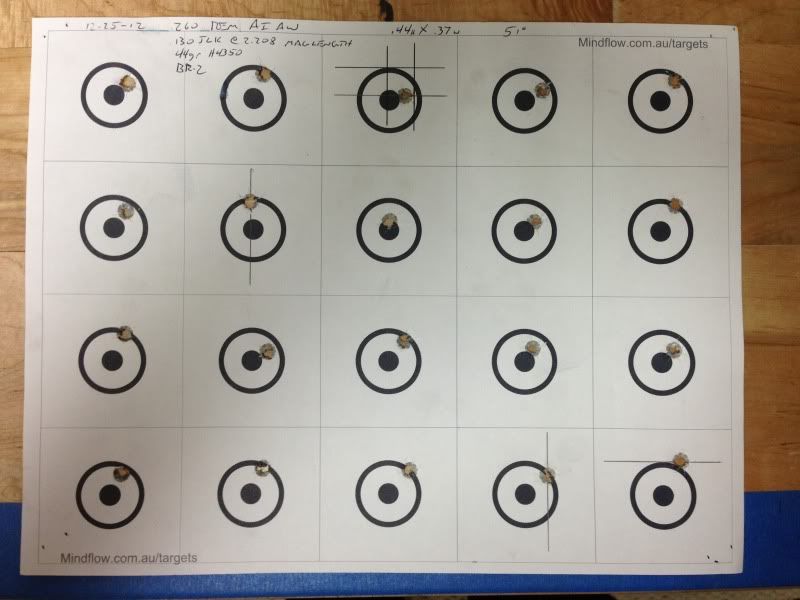

I've noticed alot of loads that guys are using are 42+ grains of H4350. At 42 grains Im getting alot of burn marks on the head stamp of the case. Flattened primers as well. I dropped the load down to 41.5 and same thing, still getting alot of burn mark on the head stamp. No ejector marks on the case at all.

Not sure what is causing this, fairly new to rifle reloading. When I backed into the velocity with Ballistics AE, I was getting 2825 fps with 42gr/140gr amax.

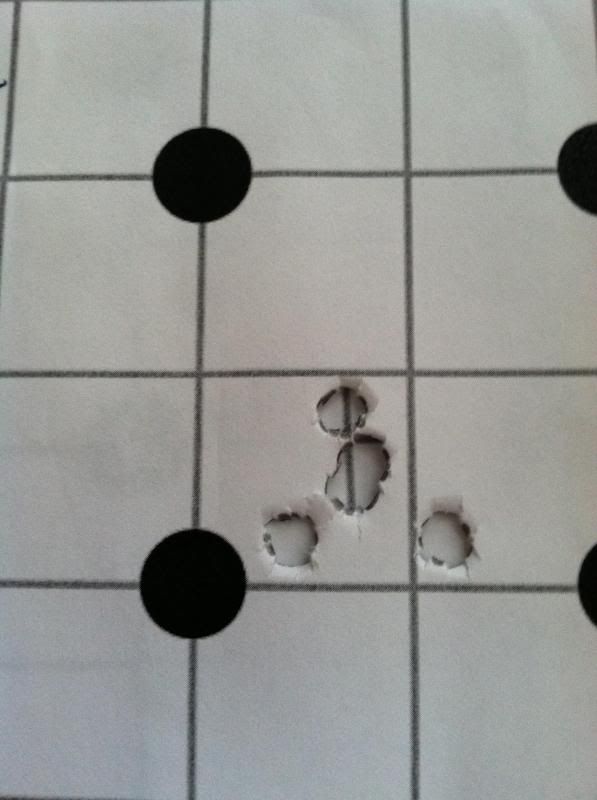

Next step will be 40.9 as I didn't think the groups were all that great with the 41.2 I tried today. What am I doing wrong?

Dale

I am using 140 grain A-Max and 142 grain Sierra Match Kings to develop the correct load.

Prvi .243 brass, Tula primers

I've noticed alot of loads that guys are using are 42+ grains of H4350. At 42 grains Im getting alot of burn marks on the head stamp of the case. Flattened primers as well. I dropped the load down to 41.5 and same thing, still getting alot of burn mark on the head stamp. No ejector marks on the case at all.

Not sure what is causing this, fairly new to rifle reloading. When I backed into the velocity with Ballistics AE, I was getting 2825 fps with 42gr/140gr amax.

Next step will be 40.9 as I didn't think the groups were all that great with the 41.2 I tried today. What am I doing wrong?

Dale