When I build rifles or rebarrel in the shop, I torque to 80 ft/lbs on standard size actions and 100 ft/lbs. on XL type actions with 1.350" breech dia.

These aren't magic numbers, just a way of being consistent. I honestly think the guns would shoot fine with half that. As long as you are not over torqueing, you can swap barrels onto the receiver 100 times and not change headspace. Each barrel is serial numbered to the host receiver. When it is tight, it is headspaced correctly. No gauges needed on each change out.

NOTE: While I triple check the headspace of the replacement barrel before shipping, I would not blame any customer for checking the headspace with a gauge before firing the first shot regardless of where the barrel came from.

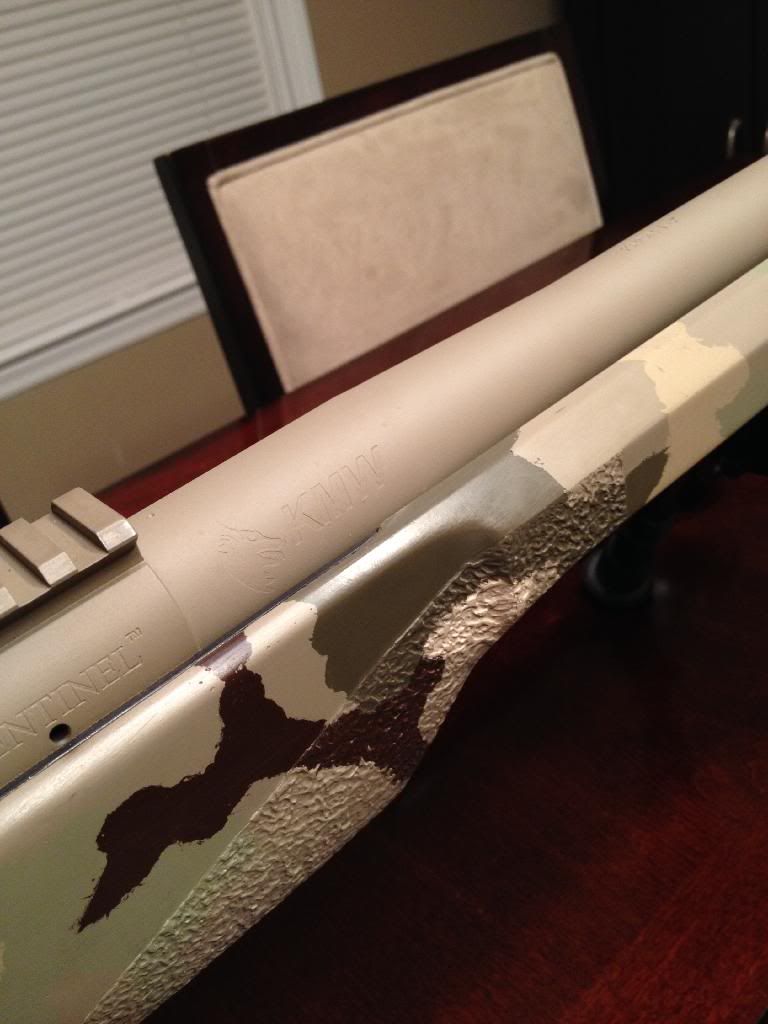

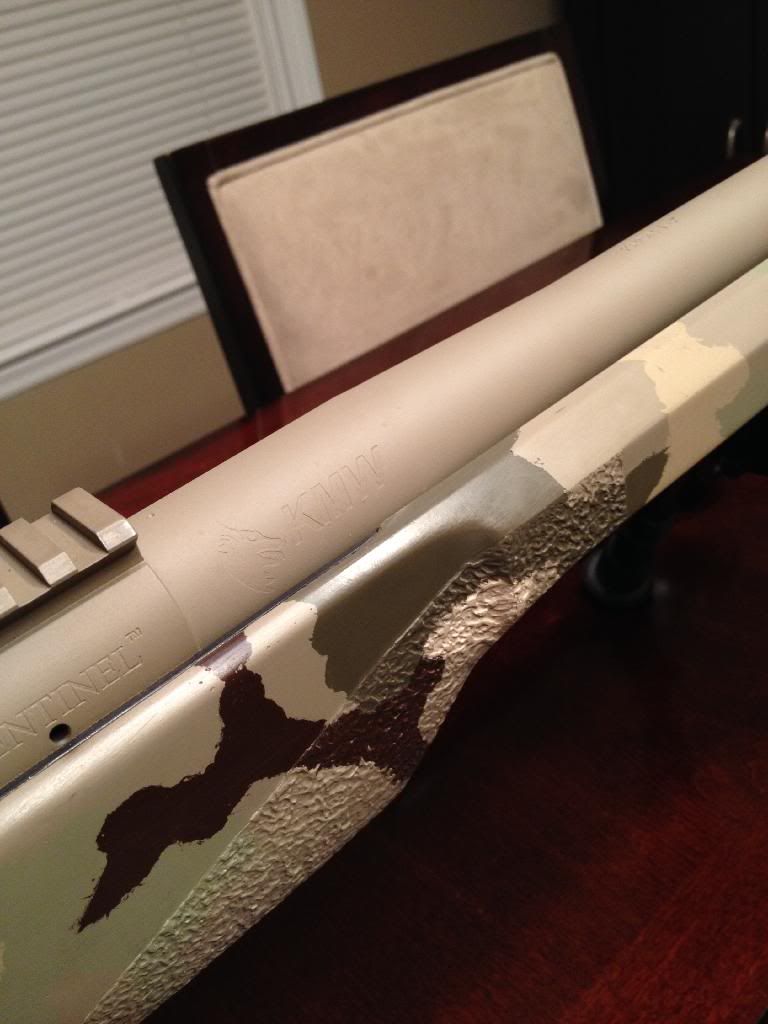

Records are kept on every rifle built. Extra barrels can be built with correct thread wire gauge, headspace, breech clearance, etc. for the original host action. I have repeatable fixture that I can use to record exactly how the barrel should clock to the original host action also. This allows all barrel markings to line up on the rifle when installed.

The TDC mark on the barrels is simply my way of timing the bore curvature while in the lathe. The same mark is used as an index to accurately align the marking on extra barrels also.

Basically you ignore the punch mark when installing the replacement barrel. Make sure that all of your threads and both shoulder surfaces are clean and then torque. There is no matching index mark on the receiver and using a torque lighter or heavier than mentioned will not vary the headspace over half a tenth if that. NOTE: You can certainly over tighten a barrel and compress the shoulder a little. Barrel steels are soft and especially when using barrels with smaller breech diameters (that result in very small shoulder areas) the smaller contact area is more prone to compression. Just no need to go that darned tight and nothing at all good to gain from it.

Jelrod1, I am glad you got them in and are pleased. Thank you for your patience and your business.