Not sure if this post belongs here or in another section, but I am curious about Melonite to smooth out my bolt cycling. I thought I recalled reading that Melonite makes an action really smooth?

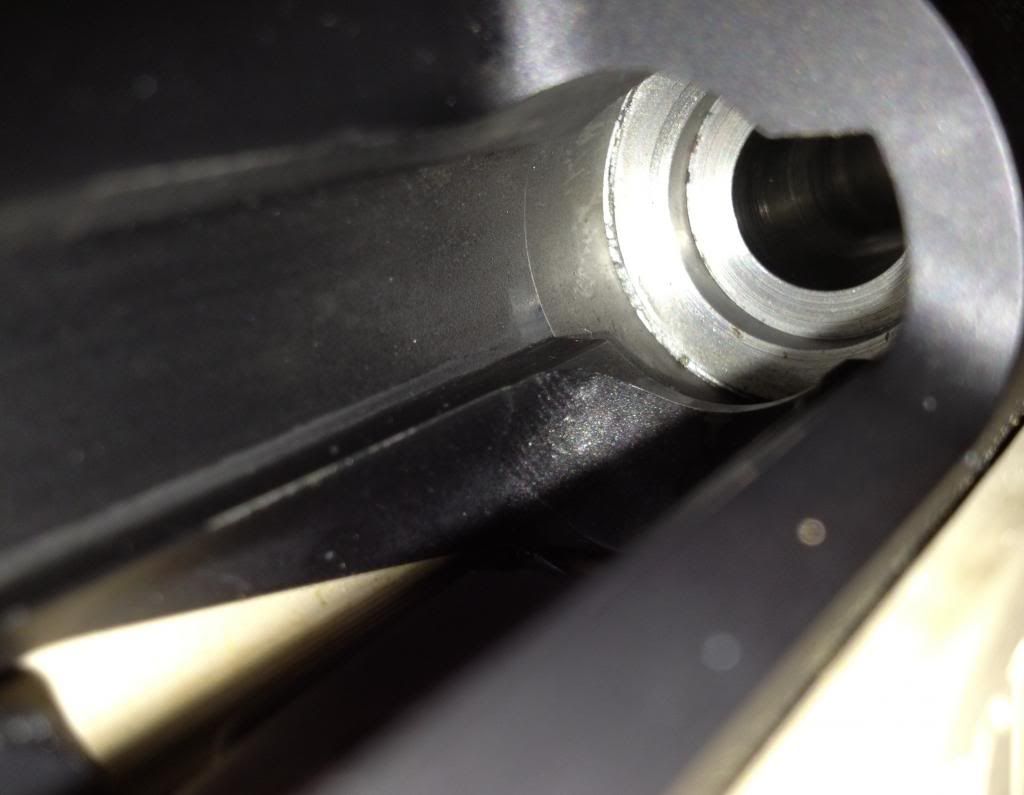

Here's my problem: I have a Defiance Rebel action that was Cerakoted and I believe this is why cycling the bolt is pretty sticky. It is not smooth at all, and chatters/skips when sliding it back. Bolt lift is o.k. though. The bolt itself is NOT coated, but the receiver and bolt raceways (everything else) is. Will this eventually wear off with thousands of cyclings? Should I look into Melonite? Can you remove Cerakote?

Thanks for any guidance you can provide!

Here's my problem: I have a Defiance Rebel action that was Cerakoted and I believe this is why cycling the bolt is pretty sticky. It is not smooth at all, and chatters/skips when sliding it back. Bolt lift is o.k. though. The bolt itself is NOT coated, but the receiver and bolt raceways (everything else) is. Will this eventually wear off with thousands of cyclings? Should I look into Melonite? Can you remove Cerakote?

Thanks for any guidance you can provide!