Updated with pics!! at the bottom!

I bought my first lathe used for $800.00 back in 2008 and have been using it to chamber, headspace, crown and thread barrels, true actions, and to fabricate a plethora of custom parts for boats and sandrails.

Its been a great machine but the 1.1 inch spindle bore limits me to short barrels between centers, or small diameter barrels through the headstock. Longer than about 19in, 1.1+ diameter barrels have been a no-go up until now.

It's an old 1989ish Smithy AT-300 3 in 1 machine, requires a different combo of gears for each thread pitch.

I'm gonna set the old AT-300 up to be used as a light duty mill and upgrade to a bigger lathe.

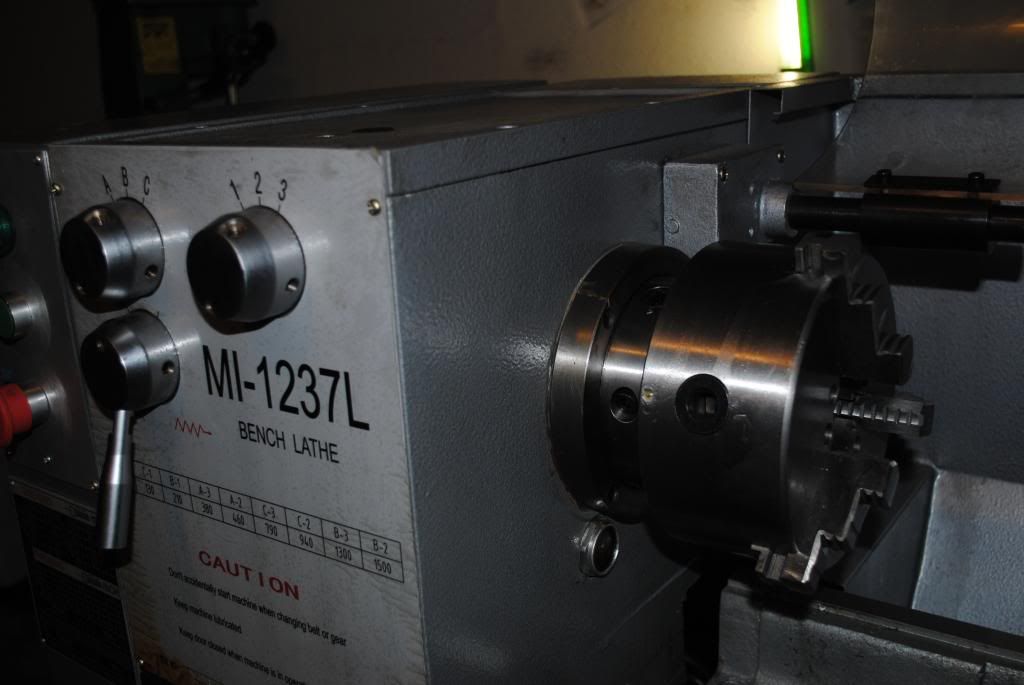

I've decided on a 12x37ish machine to replace it, the options were the grizzly G4003, The Bolton Hardware CQ9336 or the Smithy MI-1327L. They all look very similar in capabilities and in pricing as well, All three come with the "free" tool pack, consisting of a 3 jaw, 4 jaw, compound, faceplate, etc. I'm gonna guess they probably all come out of the same factory in China, just with different labels stuck on.

The Bolton:

12in x 36in Gear Head Metal Lathe With Stand Coolant System - Metal Lathes at Bolton Hardware

The Grizzly:

Grizzly.com

The Smithy:

MI-1237L Gear Drive Lathe | smithy.com

The Bolton model comes with a plethora of gears that have to be arranged to set up for different thread pitches, like my AT-300. The Grizzly and Smithy both only have a "Metric" and "inch" gear arrangements, and different pitches are accomplished with the gearbox lever settings.

I've been dealing with Smithy for years and have been very happy with their quality and customer service. Their people always seem to know the equipment, never have to transfer me to a machinist to get questions answered, etc. Its the more expensive of the three, but im leaning toward it anyway, just out of brand loyalty.

Opinions?

I bought my first lathe used for $800.00 back in 2008 and have been using it to chamber, headspace, crown and thread barrels, true actions, and to fabricate a plethora of custom parts for boats and sandrails.

Its been a great machine but the 1.1 inch spindle bore limits me to short barrels between centers, or small diameter barrels through the headstock. Longer than about 19in, 1.1+ diameter barrels have been a no-go up until now.

It's an old 1989ish Smithy AT-300 3 in 1 machine, requires a different combo of gears for each thread pitch.

I'm gonna set the old AT-300 up to be used as a light duty mill and upgrade to a bigger lathe.

I've decided on a 12x37ish machine to replace it, the options were the grizzly G4003, The Bolton Hardware CQ9336 or the Smithy MI-1327L. They all look very similar in capabilities and in pricing as well, All three come with the "free" tool pack, consisting of a 3 jaw, 4 jaw, compound, faceplate, etc. I'm gonna guess they probably all come out of the same factory in China, just with different labels stuck on.

The Bolton:

12in x 36in Gear Head Metal Lathe With Stand Coolant System - Metal Lathes at Bolton Hardware

The Grizzly:

Grizzly.com

The Smithy:

MI-1237L Gear Drive Lathe | smithy.com

The Bolton model comes with a plethora of gears that have to be arranged to set up for different thread pitches, like my AT-300. The Grizzly and Smithy both only have a "Metric" and "inch" gear arrangements, and different pitches are accomplished with the gearbox lever settings.

I've been dealing with Smithy for years and have been very happy with their quality and customer service. Their people always seem to know the equipment, never have to transfer me to a machinist to get questions answered, etc. Its the more expensive of the three, but im leaning toward it anyway, just out of brand loyalty.

Opinions?

Last edited:

![DSC_1782_zpsda692077.jpg]](http://i216.photobucket.com/albums/cc277/ken_556/DSC_1782_zpsda692077.jpg])