Hi, new to reloading so I'll try to put in as much information as possible:

-308 win -175 smk hpbt/virgin lapua brass/cci br large primers/varget powder

-RCBS press/redding competition bullet seating die/Frankford arsenal digital caliper/Hornady comparator body/30 cal insert

Basically my oal are varying +/- .1 tenth and bullet ogive on loaded round is +/- thousandths

Primer seating depth is good, not protruding out.

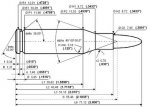

So I know meplate cuts are off, but is it normal for smk to be off by tenths?! Basically I'm getting handfuls of 2.7's to 2.8's(trying to keep OAL to 2.80) Even my loaded bullet ogives are off by +/- a couple of thousandths. I neck sized a few rounds .002- from loaded rounds using reddings competition neck sizing die and bushing = same results though. I seat my bullet seating die by having the ram in uppermost position, screw die until sleeve is compressed in and contact is made with shellholder, than back off till micrometer adjustments are in front for easy reading. I've tried seating the round,backing it off, rotating it 180 and seating it again....same results. Am I being to picky? Is it possible that it could be my dial calipers that are off? Any recommendations?

I'm sure I'm missing some information so I'll answer any questions you guys ask.

Thanks in advance!

-308 win -175 smk hpbt/virgin lapua brass/cci br large primers/varget powder

-RCBS press/redding competition bullet seating die/Frankford arsenal digital caliper/Hornady comparator body/30 cal insert

Basically my oal are varying +/- .1 tenth and bullet ogive on loaded round is +/- thousandths

Primer seating depth is good, not protruding out.

So I know meplate cuts are off, but is it normal for smk to be off by tenths?! Basically I'm getting handfuls of 2.7's to 2.8's(trying to keep OAL to 2.80) Even my loaded bullet ogives are off by +/- a couple of thousandths. I neck sized a few rounds .002- from loaded rounds using reddings competition neck sizing die and bushing = same results though. I seat my bullet seating die by having the ram in uppermost position, screw die until sleeve is compressed in and contact is made with shellholder, than back off till micrometer adjustments are in front for easy reading. I've tried seating the round,backing it off, rotating it 180 and seating it again....same results. Am I being to picky? Is it possible that it could be my dial calipers that are off? Any recommendations?

I'm sure I'm missing some information so I'll answer any questions you guys ask.

Thanks in advance!