Easier to scope a barrel than pull it off and take the mill to it, lol

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contestEasier to scope a barrel than pull it off and take the mill to it, lol

Sent from my iPhone using Tapatalk

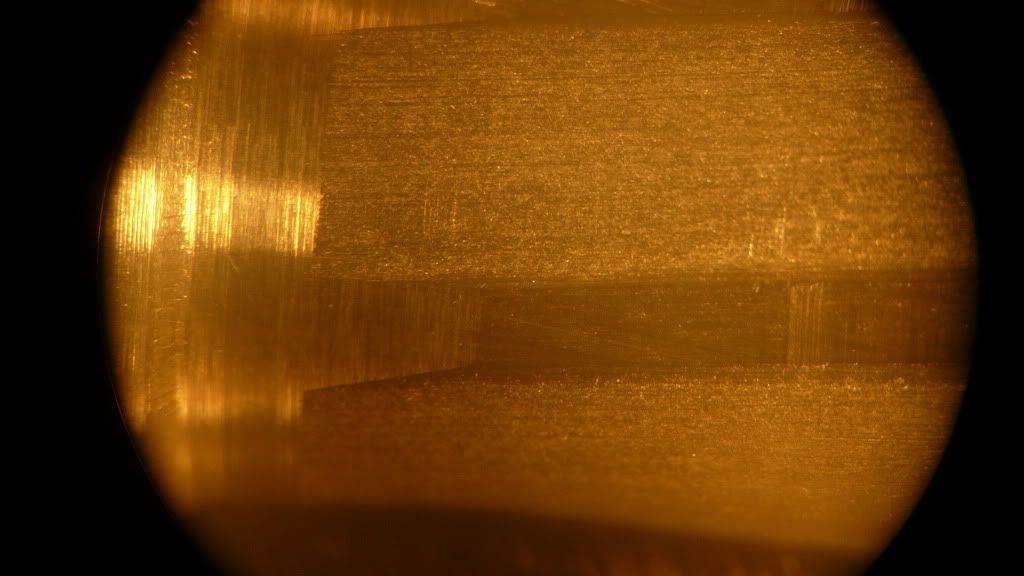

Once copper gets into the cracks you can't get it out. Then consistent repeatable accuracy will fall off.

Could the copper being in there somehow help accuracy? (To "smooth out" the bore.)I realize not having the cracks would be ideal, but it sounds like they're going to happen on a lot of calibers/barrels after just a few hundred rounds, if not sooner.

Great info!

Mr. Tooley, I have a question, my normal procedure with a barrel is to clean it every outing, 20-40 rounds for the first three hundred or so rounds, then after that it gets cleaned about every 300 rounds. I haven't noticed an issue with this practice, what are your thoughts on that?

Next question, I have heard alot of folks say that after you clean (thouroughly clean) a barrel, you should put a few rounds down the tube say before a match so that your barrel gets fouled and there will be less deviation in your "cold bore" shot. I have not noticed a huge deviation clean or "fouled", but I will sometimes, if time allows follow that practice as well, do you have any thoughts on that philosophy?

***With a few barrels early on, I was following different "barrel break-in procedures" from different manufacturers, shoot a round, clean, shoot a round clean etc... shoot five rounds clean, then on subsequent barrels I have just shot 20ish rounds on first outing, clean etc...have not noticed a difference either way, can you tell us what your thoughts are on barrel break-in?

+1. Given you are only saving the cost of a new blank, setting back is really not worth it unless you have no choice. Dumping the same dollars on a used barrel with a hope and prayer isn't a wise investment IMHO.

L

Mr. Tooley what about gas guns with smaller bores. 6 creedmoor, .243 etc etc. Is their a damage control cleaning and care you would recommend.

Hi Gentlemen I'm new to the forum and new to long range shooting. I have a 6.5 Creedmore that I'm just doing load development with so I find this thread very interesting. I' curious what Mr. Tooley thinks about bore treatments like Dyna Bore Coat that leaves a ceramic coating in the bore of your barrel and also fire lapping to smooth out and polish the bore giving coper fewer places to attach to. I would be curious how it would work in combination of fire lapping the bore to polish it cleaning it to bare metal and then coating with Dyna Bore Coat. I've coated three of my rifle barrels and it has made copper fouling clean up very quick and easy. The loss of velocity the original poster wrote about, would that not be caused by lower pressures from the longer throat now in the rifle. Sort of like having the same power charge in a larger case would result in less velocity because of less pressure. Any volume created before engagement into the leade and rifling would be like having a larger case capacity. Very interesting subject and great pictures.

Anyone have an idea of how many rounds until a .308 barrel would be eroded that badly? Maybe 7,000 or 8,000?