All loads functioned 100% today including lock back after magazine was empty. Lubricant remains SLIP 2000 EWL only.

Nice groups. Glad to hear it's running w/o a hitch now.

I've been following this and your other thread very closely, as I have a GAP-10 on order and was worried about having the reliability issue you described and then having to incur the expense and hassle of returning it to George and Co for tuning.

Until I have more time to reload (as in retirement), I'll be shooting mostly factory match ammo supplemented by what handloading I'm able to do.

By way of contrast, I've now got just under 200-rds of various .308 factory thru my recently received LMT LM8 ("slickside") MRP. It came w/ the 16" C/L barrel but I had also ordered the 18" SS 1/11.25 tube, received it, and that's what I've been shooting with. It's scoped w/ a Leupy 1x-6x Mk6 (w/the illumin TMR reticle) and I installed a Geissele SSA-E.

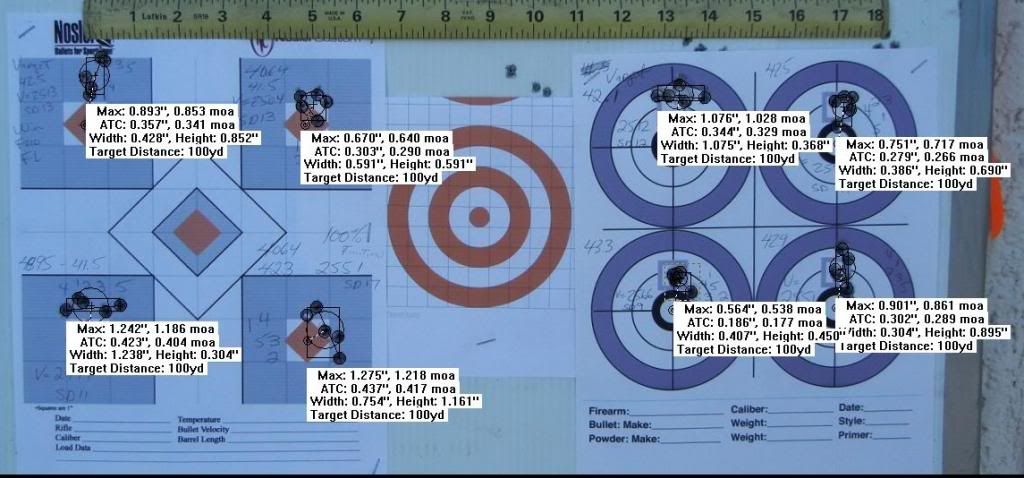

Started w/ breaking in the 18" barrel and, this being my first AR in 7.62/.308, getting settled in and used to how it shoots. I've got a lot of trigger time w/ M1As but this animal is different. Anyway, initial 5-shot groups w/ 168 FGMM were right at or just over 1 MOA @ 100yds, proned out and using a bipod and rear bag. Last outing, after cleaning and re-torquing the SS barrel (which included removing and cleaning both barrel screws), groups with that ammo were .90-to-.75MOA. The best group was with Hornady 155gn AMAX which printed a .60MOA @ 100yds, and I'm still getting used to this rifle. And, FWIW, since receiving the LM8 I have

NOT had one FTF, FTE or other malf w/ any ammo, including some several boxes of PMC 308 147gn FMJ that I shot on one of the first outings.

For the money you invest in these top tier .308 ARs, I don't think you should have to settle for getting either "precision" (or "match"-type) accuracy

or 100% reliability but not both, certainly with quality factory loads, as a poster in the other thread suggested.

And accuracy aside, I don't think reloading for them with the expectation that they'll function properly should, within reason, be so difficult that you'll have to go through a hundred handloads just to find one that will work.

Still looking forward to my GAP-10; this is just my 2-cents on the issue. Thanks for your posts.