I want to bring forth a topic I don't recall seeing alot of discussion about.

I've recently got into 3D printing, with the emphasis on reloading. We as reloaders are typically making due with what can find and modify off the shelf. 3DP brings an entire new level to having what you want.

From Powder funnels that are a perfect fit, reloading trays, to bullet feeder, Press parts, holders, organizers....

Thingaverse is good place for designs, but unfortunately alot of the designers have no idea how to make something that prints for everybody, so you get alot of Crap.

I've been learning Fusion 360, this is an amazing software, free for us hobbyist.

Fusion 360 | Free Software for Hobbyists, Startups & Makers | Autodesk

I just want to try and kick start any discussion or sharing of ideas, designs, ect.

If you haven't seen it, the openbulletfeeder project is great.

openBulletFeeder - DIY bullet feeder by AmmoMike83

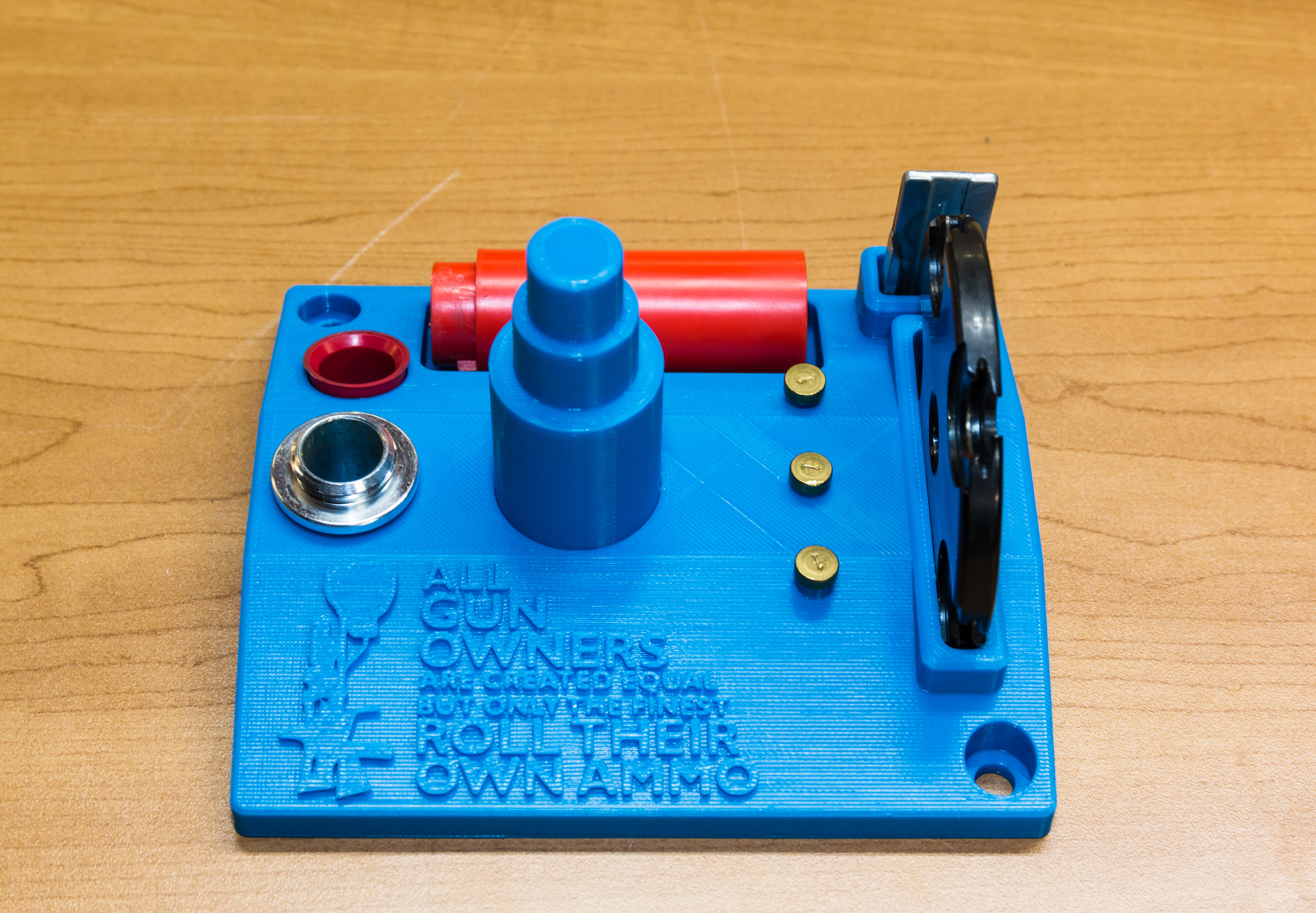

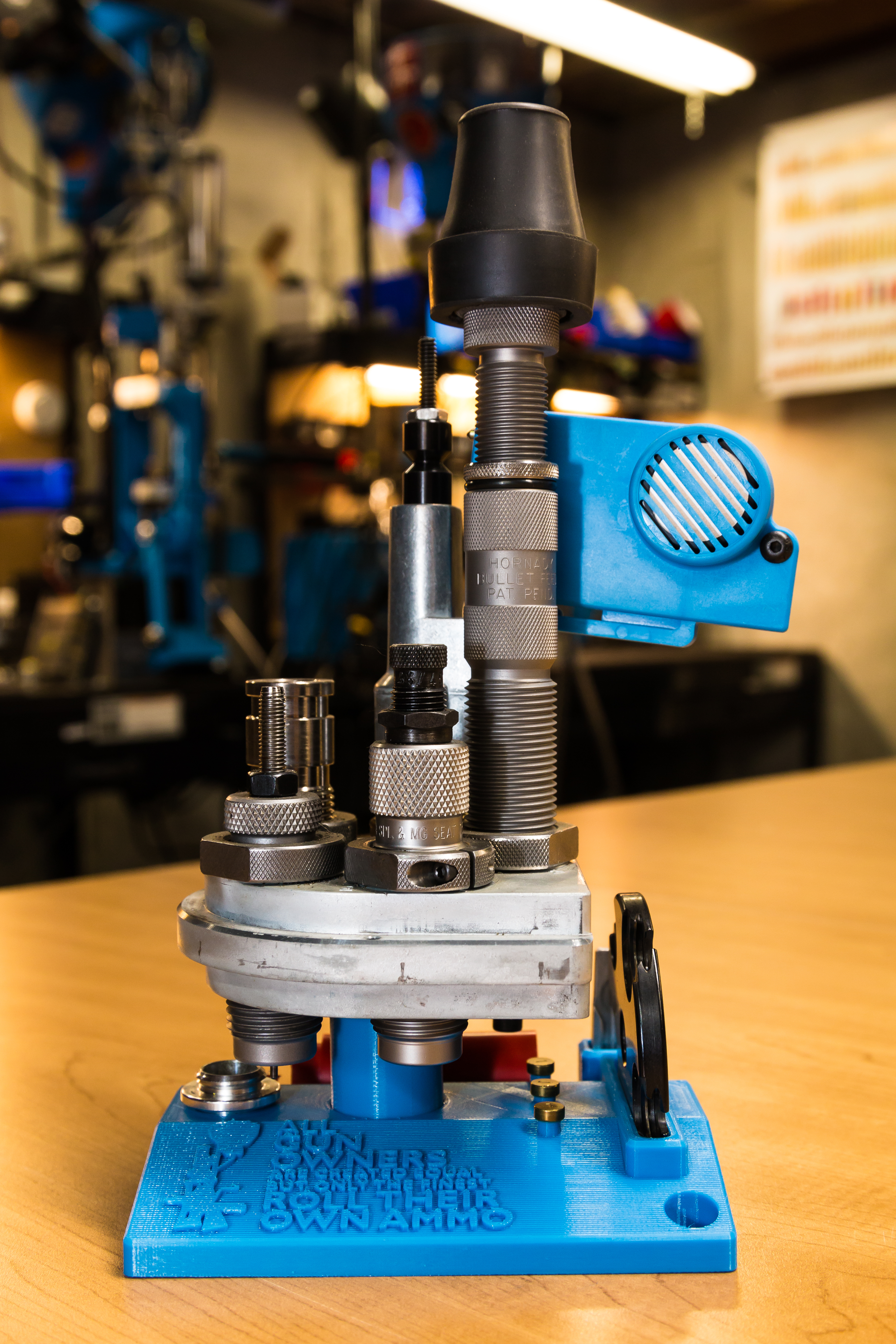

Here are my published designs, with more to come, just a few select pics below.

Ruebarb's Thingiverse Profile

I've recently got into 3D printing, with the emphasis on reloading. We as reloaders are typically making due with what can find and modify off the shelf. 3DP brings an entire new level to having what you want.

From Powder funnels that are a perfect fit, reloading trays, to bullet feeder, Press parts, holders, organizers....

Thingaverse is good place for designs, but unfortunately alot of the designers have no idea how to make something that prints for everybody, so you get alot of Crap.

I've been learning Fusion 360, this is an amazing software, free for us hobbyist.

Fusion 360 | Free Software for Hobbyists, Startups & Makers | Autodesk

I just want to try and kick start any discussion or sharing of ideas, designs, ect.

If you haven't seen it, the openbulletfeeder project is great.

openBulletFeeder - DIY bullet feeder by AmmoMike83

Here are my published designs, with more to come, just a few select pics below.

Ruebarb's Thingiverse Profile