I started off with reloading using an RCBS balance beam scale. I happily purchased one of the earlier digital strain-gauge scales when they become available, an RCBS Model 90 made by Ohaus. This likely was purchased in 1989-1990. Several years later I also bought an RCBS Range Master strain-gauge scale, also made by Ohaus, as I need to weigh 750 grains or more, outside of the Model 90's capabilities. I've used it intermittently, but the Model 90 was my go-to scale for most handloading projects.

I enjoy handloading but begrudge the drudgery of individually weighing powder charges. My usual workflow is to throw a charge near the desired weight using a Redding LR-1000 volumetric measure, then trickle to goal on the Model 90 scale. The newer integrated powder dispenser/scale units were appealing and I have an RCBS Charge Master Lite. Again, this unit utilizes a strain-gauge scale.

Strain-gauge scales have two primary faults, even with high-end units. First, the readings are subject to drift, due to temperature change, EM fields, or any movement (all precision scales will be sensitive to even subtle air currents and often need to be shielded). Also, strain gauge scales are relative slow to come to a final reading (compared to magnetic force restoration scales) and also take longer to adjust to any added tiny weight (such as one or two kernels of H4350, which runs about 0.02 to 0.03 grains/kernel). Magnetic force restoration scales are more expensive, but also can be more accurate and avoid these faults. A good comparison can be found at:

"Magnetic force restoration balance verses strain gauge digital scale."

My beloved RCBS Model 90 has served me well for decades but last year developed worsening drift leaving me untrusting of the results, even if I carefully watched the displayed "negative" weight with the scale pan removed. The Range Master scale (the original model, not the RM 750 or RM 2000) has unfortunately always been more subject to drift than the Model 90. I started looking for a replacement.

A friend of mine better versed in metrology cautioned me, "I have also learned that some scale/balance manufacturers play games with the final readout on their scale digital display. They calibrate with a 50 gram or 100 gram weight but convert the measured weight in grams to the grain equivalent in a lookup table. Depending on how this is carried out it rounds off the actual final (converted to grains) readout is in error by as much as +/- 0.1 grain."

Creedmoor Sports last year introduced their TRX-925 scale, made in China but to impressive specifications and $350 (and also a strain-gauge scale):

They addressed my friend's concern: "Our specialized programming of the TRX-925 sets the Creedmoor Sports TRX-925 apart from other scales in the market. While measuring in grains may seem like the norm, the vast majority of scales on the market utilize grams as their native unit of measure and simply convert the measured weight from grams to grains by using a formula. Unfortunately, this method of behind-the-scenes conversion generates significant rounding errors that can affect the reported weight. With the ability of the TRX-925 to read down to 0.01 grains, eliminating the gram/grain conversion process, making this scale the only reloading scale that offers true +/-.01 grain accuracy and measuring natively in grains was an absolute must to achieve the level of accuracy the Creedmoor Sports TRX-925 demonstrates."

I bought one of these as a replacement for the old RCBS and have been happy with it. The display is easy to read from a variety of angles, the top has plenty of room to place a powder trickler, and it does seem to be quite accurate. It is subject to drift even when warmed up for an hour or three, but is less problematic than my older RCBS scales. Better yet, they include three F1 grade calibration weights of 2, 10, and 50 grams. My older three RCBS scales came with calibration weights, but no class or specification was provided. This is important:

https://labbalances.net/blogs/blog/guide-to-calibration-weights

I mentioned that I dislike the drudgery of weighing individual charges, so I was intrigued by Adam MacDonald's Autotrickler. I have Version 3 which utilizes an A&D FX-120i magnetic force restoration scale. The Autotrickler has sped up my case charging by at least 30-40% and now my back doesn't hurt afterwards in the evening. I am on the pre-order list for an Ingenuity Precision trickler to use with the Autotrickler, but I am utterly happy with the A&D FX-120i scale. This reads to milligram precision, or to 0.02 grains which is one kernel of H4350 and more than sufficient to my needs.

I did find it interesting that the A&D weighs in grains to 0.02 grains while the TRX-925 strain gauge scale claims to weigh to 0.01 grains. But how to evaluate this?

Using those three supplied F-1 grade calibration weights would be a good start, but I thought that more precise weights in a wider range would be a better measure. However, anything more precise than F-1 grade weights gets very expensive quickly. I did stumble across a used lovely set of pristine Troemner calibration weights on eBay for a great price. These were ASTM Class 1, which is a moderately more precise standard than the F-1 weights, and they include a 1, 2, 5, 10, 20, 50 and 100 gram weight (with two each of the 2 and 10 gram weights). The 50 gram weights seemed particularly useful, as I use an Area 419 powder cup. That cup weighs 747 grains and with 40 grains of H4350 the total is quite close to 50 grams (771.62 grains).

With these Class 1 calibration weights available, I thought a scale comparison would be useful. I set up all five scales, warmed them up, and then calibrated each according to its instructions in the respective manual (I am an OCD geek and save manuals!).

Once completed, I took an assortment of weights and weighed them on the five scales. This included the old RCBS 50 gram weights included with the Range Master and Charge Master Lite, and the two 250 grain weights included with the Model 90. I also used the three F-1 class weights included with the TRX-925 scale and the seven different weighs of the Troemner set.

Keep in mind that only the Troemner weights should be considered as "true" to the milligram with the three F-1 weights likely quite close. The RCBS weights were not described as meeting any particular standard and may well have been F-2 or even M-1 grade. Not all of the scales would read in grams, so I did all of the weighing in grain results, and calculated a nominal gram to grain equivalent for all of the tested weights.

Unsurprisingly, the A&D FX-120i was the "gold standard" and correctly read all of the F-1 and ASTM Class 1 weights in grams to precisely the correct reading (to the milligram level of the display, such as 50.000 grams).

The TRX-925 was very good. It does suffer from the inherent strain-gauge limitation of a slow response and will indeed display drift even after three hours of use. That Area 419 cup weighs 747.52 grains and if I note the "empty" weight varying more than 0.05 grains from "-747.52", I re-zero the scale. The other limitation is repeatability. If I take the ASTM Class 1 50 gram weight and put it on and off the A&D scale repeatedly, it always reads 771.62 grains. However, the TRX-925 is inconsistent and will display from 771.60 to 7711.64 grains. The 771.62 is the most frequent reading, but it does vary +/- by 0.02 grains, casting grave doubt on the claimed 0.01 grain accuracy!

The RCBS Charge Master Lite was the top performer of the scales reading to 0.1 grains. If 0.1 grain accuracy is sufficient to your needs, this would be a suitable scale and even better if it will consistently throw an accurate charge to the targeted weight. (Keep in mind that all of this testing involved a sample size of ONE unit each). Again, one must watch for scale drift.

The other two (much older) RCBS scales were sufficiently accurate for almost all reloading tasks unless you are trying to absolutely minimize velocity standard deviation for long range shooting. (The benchrest boys use Harrell volumetric measures with relatively poor consistency, so I think velocity SD is inconsequential for them at 100-300 yards). Having just seen a friend's new Dillon inexpensive strain gauge scale immediately fail, I think one does get what you pay for, and a quality scale like those from Ohaus are worth the coin.

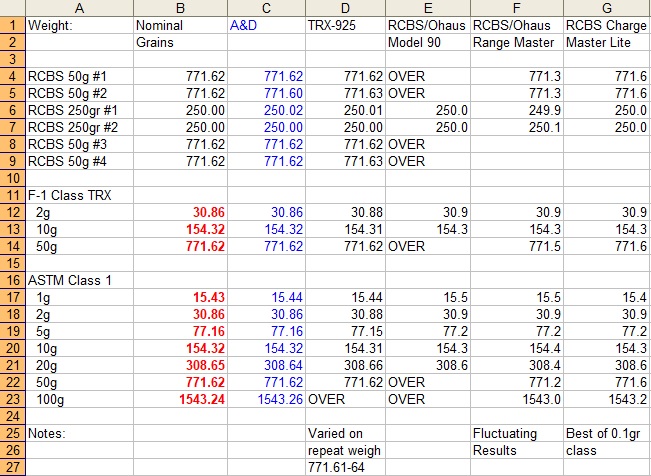

I'm attaching a JPG of an Excel spreadsheet displaying the results.

So what should you get? It depends on what you want to do. If excellent accuracy and precision is required, the A&D FX-120i is a superb scale and available for $550 from CE Products. It also interfaces with the Autotrickler, and using the Autotrickler with a slow-reading strain-gauge scale would be pointless. If you aren't using an Autotrickler, one challenge with the A&D scale is that the scale "top" is not big enough to hold a manual powder trickler. You'd need to make a hole in the breeze shield and find a trickler with a long enough dispensing arm and make a suitable height base.

If you don't plan to use an Autotrickler and don't mind the slower readings and need to watch for drift, the TRX-925 is indeed quite accurate and well designed for a variety of handloading tasks. Mine lives on my reloading bench and gets used frequently.

If your needs are met with about +/- 0.1-0.2 grains accuracy and you'd like an automated device, the RCBS Charge Master Lite works well and is much less expensive then the Autotrickler setup. It also will handle a 100 gram weight. Watch for scale drift!

If you do elect to go with an inexpensive strain gauge scale (say, sub $150), do yourself a favor and go to eBay and buy a few F-1 calibration weights of 2, 10, and 50 grams like those that come with the TRX-925. These are surprisingly inexpensive, but will let you ensure that your scale is being honest. Heck, do this even you buy an more expensive scale. Like Reagan said about the Soviets, "Trust, but verify!"

I enjoy handloading but begrudge the drudgery of individually weighing powder charges. My usual workflow is to throw a charge near the desired weight using a Redding LR-1000 volumetric measure, then trickle to goal on the Model 90 scale. The newer integrated powder dispenser/scale units were appealing and I have an RCBS Charge Master Lite. Again, this unit utilizes a strain-gauge scale.

Strain-gauge scales have two primary faults, even with high-end units. First, the readings are subject to drift, due to temperature change, EM fields, or any movement (all precision scales will be sensitive to even subtle air currents and often need to be shielded). Also, strain gauge scales are relative slow to come to a final reading (compared to magnetic force restoration scales) and also take longer to adjust to any added tiny weight (such as one or two kernels of H4350, which runs about 0.02 to 0.03 grains/kernel). Magnetic force restoration scales are more expensive, but also can be more accurate and avoid these faults. A good comparison can be found at:

"Magnetic force restoration balance verses strain gauge digital scale."

My beloved RCBS Model 90 has served me well for decades but last year developed worsening drift leaving me untrusting of the results, even if I carefully watched the displayed "negative" weight with the scale pan removed. The Range Master scale (the original model, not the RM 750 or RM 2000) has unfortunately always been more subject to drift than the Model 90. I started looking for a replacement.

A friend of mine better versed in metrology cautioned me, "I have also learned that some scale/balance manufacturers play games with the final readout on their scale digital display. They calibrate with a 50 gram or 100 gram weight but convert the measured weight in grams to the grain equivalent in a lookup table. Depending on how this is carried out it rounds off the actual final (converted to grains) readout is in error by as much as +/- 0.1 grain."

Creedmoor Sports last year introduced their TRX-925 scale, made in China but to impressive specifications and $350 (and also a strain-gauge scale):

Creedmoor Sports TRX-925 Precision Reloading Scale

Creedmoor Sports TRX-925 Precision Reloading Scale When every tenth counts, this scale measures to the hundredths. Introducing the TRX-925 precision digital reloading scale by Creedmoor Sports. Our development team set out to create one of the most accurate and precise scales on the...

www.creedmoorsports.com

They addressed my friend's concern: "Our specialized programming of the TRX-925 sets the Creedmoor Sports TRX-925 apart from other scales in the market. While measuring in grains may seem like the norm, the vast majority of scales on the market utilize grams as their native unit of measure and simply convert the measured weight from grams to grains by using a formula. Unfortunately, this method of behind-the-scenes conversion generates significant rounding errors that can affect the reported weight. With the ability of the TRX-925 to read down to 0.01 grains, eliminating the gram/grain conversion process, making this scale the only reloading scale that offers true +/-.01 grain accuracy and measuring natively in grains was an absolute must to achieve the level of accuracy the Creedmoor Sports TRX-925 demonstrates."

I bought one of these as a replacement for the old RCBS and have been happy with it. The display is easy to read from a variety of angles, the top has plenty of room to place a powder trickler, and it does seem to be quite accurate. It is subject to drift even when warmed up for an hour or three, but is less problematic than my older RCBS scales. Better yet, they include three F1 grade calibration weights of 2, 10, and 50 grams. My older three RCBS scales came with calibration weights, but no class or specification was provided. This is important:

https://labbalances.net/blogs/blog/guide-to-calibration-weights

I mentioned that I dislike the drudgery of weighing individual charges, so I was intrigued by Adam MacDonald's Autotrickler. I have Version 3 which utilizes an A&D FX-120i magnetic force restoration scale. The Autotrickler has sped up my case charging by at least 30-40% and now my back doesn't hurt afterwards in the evening. I am on the pre-order list for an Ingenuity Precision trickler to use with the Autotrickler, but I am utterly happy with the A&D FX-120i scale. This reads to milligram precision, or to 0.02 grains which is one kernel of H4350 and more than sufficient to my needs.

I did find it interesting that the A&D weighs in grains to 0.02 grains while the TRX-925 strain gauge scale claims to weigh to 0.01 grains. But how to evaluate this?

Using those three supplied F-1 grade calibration weights would be a good start, but I thought that more precise weights in a wider range would be a better measure. However, anything more precise than F-1 grade weights gets very expensive quickly. I did stumble across a used lovely set of pristine Troemner calibration weights on eBay for a great price. These were ASTM Class 1, which is a moderately more precise standard than the F-1 weights, and they include a 1, 2, 5, 10, 20, 50 and 100 gram weight (with two each of the 2 and 10 gram weights). The 50 gram weights seemed particularly useful, as I use an Area 419 powder cup. That cup weighs 747 grains and with 40 grains of H4350 the total is quite close to 50 grams (771.62 grains).

With these Class 1 calibration weights available, I thought a scale comparison would be useful. I set up all five scales, warmed them up, and then calibrated each according to its instructions in the respective manual (I am an OCD geek and save manuals!).

Once completed, I took an assortment of weights and weighed them on the five scales. This included the old RCBS 50 gram weights included with the Range Master and Charge Master Lite, and the two 250 grain weights included with the Model 90. I also used the three F-1 class weights included with the TRX-925 scale and the seven different weighs of the Troemner set.

Keep in mind that only the Troemner weights should be considered as "true" to the milligram with the three F-1 weights likely quite close. The RCBS weights were not described as meeting any particular standard and may well have been F-2 or even M-1 grade. Not all of the scales would read in grams, so I did all of the weighing in grain results, and calculated a nominal gram to grain equivalent for all of the tested weights.

Unsurprisingly, the A&D FX-120i was the "gold standard" and correctly read all of the F-1 and ASTM Class 1 weights in grams to precisely the correct reading (to the milligram level of the display, such as 50.000 grams).

The TRX-925 was very good. It does suffer from the inherent strain-gauge limitation of a slow response and will indeed display drift even after three hours of use. That Area 419 cup weighs 747.52 grains and if I note the "empty" weight varying more than 0.05 grains from "-747.52", I re-zero the scale. The other limitation is repeatability. If I take the ASTM Class 1 50 gram weight and put it on and off the A&D scale repeatedly, it always reads 771.62 grains. However, the TRX-925 is inconsistent and will display from 771.60 to 7711.64 grains. The 771.62 is the most frequent reading, but it does vary +/- by 0.02 grains, casting grave doubt on the claimed 0.01 grain accuracy!

The RCBS Charge Master Lite was the top performer of the scales reading to 0.1 grains. If 0.1 grain accuracy is sufficient to your needs, this would be a suitable scale and even better if it will consistently throw an accurate charge to the targeted weight. (Keep in mind that all of this testing involved a sample size of ONE unit each). Again, one must watch for scale drift.

The other two (much older) RCBS scales were sufficiently accurate for almost all reloading tasks unless you are trying to absolutely minimize velocity standard deviation for long range shooting. (The benchrest boys use Harrell volumetric measures with relatively poor consistency, so I think velocity SD is inconsequential for them at 100-300 yards). Having just seen a friend's new Dillon inexpensive strain gauge scale immediately fail, I think one does get what you pay for, and a quality scale like those from Ohaus are worth the coin.

I'm attaching a JPG of an Excel spreadsheet displaying the results.

So what should you get? It depends on what you want to do. If excellent accuracy and precision is required, the A&D FX-120i is a superb scale and available for $550 from CE Products. It also interfaces with the Autotrickler, and using the Autotrickler with a slow-reading strain-gauge scale would be pointless. If you aren't using an Autotrickler, one challenge with the A&D scale is that the scale "top" is not big enough to hold a manual powder trickler. You'd need to make a hole in the breeze shield and find a trickler with a long enough dispensing arm and make a suitable height base.

If you don't plan to use an Autotrickler and don't mind the slower readings and need to watch for drift, the TRX-925 is indeed quite accurate and well designed for a variety of handloading tasks. Mine lives on my reloading bench and gets used frequently.

If your needs are met with about +/- 0.1-0.2 grains accuracy and you'd like an automated device, the RCBS Charge Master Lite works well and is much less expensive then the Autotrickler setup. It also will handle a 100 gram weight. Watch for scale drift!

If you do elect to go with an inexpensive strain gauge scale (say, sub $150), do yourself a favor and go to eBay and buy a few F-1 calibration weights of 2, 10, and 50 grams like those that come with the TRX-925. These are surprisingly inexpensive, but will let you ensure that your scale is being honest. Heck, do this even you buy an more expensive scale. Like Reagan said about the Soviets, "Trust, but verify!"