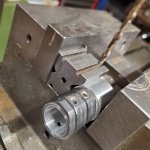

My WOA SPR gas block journal OD is measuring 0.752 and my Geiselle super gas block ID is 0.750. So looking at 0.002 interference.

According to ChatGPT, if I heat the gas block to 450 degrees, and the barrel is in the freezer overnight, it should gain me 0.0021 clearance for a thermal fit.

Yes I understand that I can hone the gas block and polish the journal.

Anyways, am I crazy to be concerned about the gas block constricting the bore once everything comes back to room temperature? Main concern for constricting is the bore would be affecting accuracy and durability.

I know that a lot of folks have done thermal fits with their WOA barrels but wanted to know what level of interference starts being too much. I presume there is a safe limit.

Flame away.

According to ChatGPT, if I heat the gas block to 450 degrees, and the barrel is in the freezer overnight, it should gain me 0.0021 clearance for a thermal fit.

Yes I understand that I can hone the gas block and polish the journal.

Anyways, am I crazy to be concerned about the gas block constricting the bore once everything comes back to room temperature? Main concern for constricting is the bore would be affecting accuracy and durability.

I know that a lot of folks have done thermal fits with their WOA barrels but wanted to know what level of interference starts being too much. I presume there is a safe limit.

Flame away.