- Feb 15, 2017

- 29

- 41

Disclaimer: I don’t post much so apparently I’ve saved up for this one. I put this together during some spare time when home on leave and I won’t be able to refine this for another year. This isn’t a full detailed review of the .277 Fury cartridge, I didn’t have time to do a full Chrono and accuracy, everything I slapped together was AdHoc. SO I admit to not doing a complete job and the errors in my method, I will just post the results for your own determination.

Several months ago, I decided with all of the Washington and Oregon gun control idiocracy against gas-guns I wanted a short, compact bolt gun that wasn’t an NFA stamp’er, a general multipurpose tool. I had a ARC Nucleus Gen 1 that I’ve had since Ted introduced them and never could get it to feel right in a rifle between 25 CM, 6.8 Western, and .284 Win barrels of different lengths. After researching the .277 Fury / 6.8x51mm cartridge (not the SPEAR rifle) from Sig I figured I’d give it a shot for the reported performance in A 16” barrel. I have listened to all of the podcasts and scrubbed the forums for info on shooting the .277 Fury, but all of it was completely speculative information, not from functional use. Even Ron Spomer had a podcast talking about how a .277 Fury might “BLOW UP A RIFLE!!” My opinion, disappointing ignorance in rifle construction, and 80k psi max (hybrid case) cartridge is not going to blow up a bolt rifle rated to 120K+PSI, otherwise SAMMI never would of approved it. If you slapped a .277 Fury barrel on a AR-10 (not the SIG SPEAR), you might have cause for concern, but not a good bolt action, again, in my opinion.

For ~16” barrel cartridge selection, I have a 16” .308 gasser and that has it’s purpose. I looked at the 8.6 CM/Blackout and have serious skepticism about the marketing vs. performance and .375 Raptor was cool, but too boutique. After looking across the expanse of the internet, or just asking Google, I found ammo for an acceptable price and also found someone who offers Savage pre-fits chambered in .277 Fury. Here is the resulting rifle.

Action: ARC Nucleus Gen 1 (30 MOA rail, 19lb striker spring)

Tigger: Huber 2-stage

Barrel: McGowen 16.5”, .277 Fury, 1-7”R twist, Savage Pre-Fit, ARC BARLOC

Stock: Manners TA (Altus Highland Camo), Devcon Pillar bedded

Bottom Metal: Badger M5 Enhanced

Scope: Nightforce NX8 2.5-20x50

Rings: ARC

Muzzle: Silencer Co Single Baffle Break

Can: Silencer Co Harvester 300

Total weight: 10lbs (a bit heavier than I wanted)

AMMO: There are current 3x versions of the .277 Fury ammo on the market from Sig. The 132gr Ball (standard case), the 130gr VENARI Soft Point (standard case), and the 150gr Elite Bonded Poly tip (Hybrid case). These all can be found at online vendors and I was able to secure plenty of rounds of the 132gr Ball and 150gr Hybrid for prices that didn’t make me sick to my stomach, or get scammed by some online F’head.

This is where it gets interesting…

As you can see the box velocity for 16in and 24in barrel lengths for both the standard load and higher pressure “hybrid’ load. Box velocity for the 150gr Hybrid case is 2830fps for a 16” barrel and 3120fps for a 24” barrel! That’s outpacing the .270 Win.

The Gen 1 Nucleus is finally at home and feels right in this compact rifle with it’s short stout bolt throw. The rifle is easy pointing and easy to carry, I am very happy with how it all came together.

For the ammo: The 132gr Ball is soft shooting and really pleasing to shoot in the shorty rifle, recoil on par with 6.5 CM or 6.5x47L. The 150gr Hybrid, is definitely spicer in recoil, but not significantly so. In this rifle set up, this doesn’t shoot like my Dad’s old wood stock 30-06’s where after a few rounds you are picking up a subconscious flinch, it is easy like Sunday morning. The ammo performance to barrel length make for a really pleasing Bolt gun.

This is where my testing/scientific method goes to shit as I was out of time and due to the surrounding environment, did not want to shoot without a can on; I was shooting on our property, but harvest was going on the properties adjacent, no need to spook the Pickers, the bullet reports were enough to unsettle them.

When I finally got the Lab Radar to work with the suppressor on the rifle, I had gone through the 132gr Ball ammo I had with me at the table, so no results to report there, which I regret terribly. But….

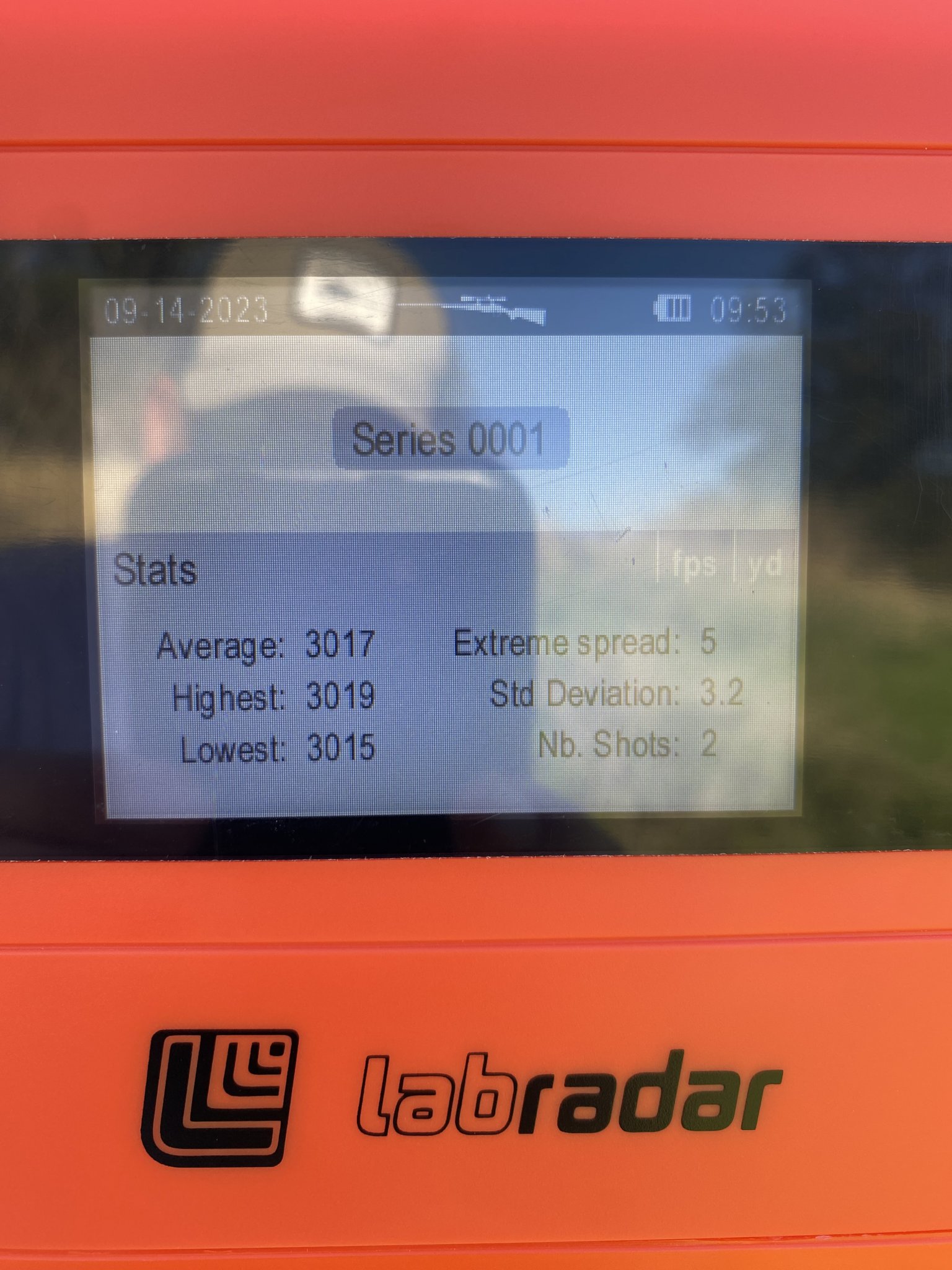

Yeah, that reads right, 3015fps and 3019fps for the 2 of 5 rounds I could get to record on the Lab Radar (yes, I know this isn’t a complete shot spread SD/ES average so take the SD of 3.2 with a health dose of skepticism). This was WITH the Harvester 300 can ON, which is a long suppressor. However I do not believe that increasing box listed velocity from 2830fps to 3017fps is because of the can, ~50fps sure, but not 187fps.

Here is a look at the primers to show signs of pressure. You can definitely see the pressure signs on the Hybrid case primer.

As I stated in the beginning, not a complete report. I would love to group the gun with this off-the-shelf ammo and then take it out to distance. I will say I love the feel of the rifle with the short barrel and it shoots beautifully. I think the .277 Fury has a lot of potential if people can get over the ”new tech” of it, a 150gr bullet moving at 3015fps out of a 16” barrel is significant. We’ll see if I still have rifling in a 1000 rounds through the barrel, but this isn’t a match gun. For perspective, my 6.8 Western with a 24” barrel shoots 162gr Copper Impacts at 2960fps! That is a short mag cartridge with a lot more powder for like performance. Arguably, the 6.8 Western will probably do better with the heavier +170gr .277 bullets than the .277 Fury Hybrid just due to space for slower burning powders. For now the .277 Fury in this shorty rifle worked out a lot better than I expected.

Take what you want from this report, it’s just raw data.

For my Marine brethren, Crayons and Bourbon is in the corner.

For the Trolls, White Claws and lotion is in the other, do what you want, just don’t look us in the eye.

S/F

Elvis

Several months ago, I decided with all of the Washington and Oregon gun control idiocracy against gas-guns I wanted a short, compact bolt gun that wasn’t an NFA stamp’er, a general multipurpose tool. I had a ARC Nucleus Gen 1 that I’ve had since Ted introduced them and never could get it to feel right in a rifle between 25 CM, 6.8 Western, and .284 Win barrels of different lengths. After researching the .277 Fury / 6.8x51mm cartridge (not the SPEAR rifle) from Sig I figured I’d give it a shot for the reported performance in A 16” barrel. I have listened to all of the podcasts and scrubbed the forums for info on shooting the .277 Fury, but all of it was completely speculative information, not from functional use. Even Ron Spomer had a podcast talking about how a .277 Fury might “BLOW UP A RIFLE!!” My opinion, disappointing ignorance in rifle construction, and 80k psi max (hybrid case) cartridge is not going to blow up a bolt rifle rated to 120K+PSI, otherwise SAMMI never would of approved it. If you slapped a .277 Fury barrel on a AR-10 (not the SIG SPEAR), you might have cause for concern, but not a good bolt action, again, in my opinion.

For ~16” barrel cartridge selection, I have a 16” .308 gasser and that has it’s purpose. I looked at the 8.6 CM/Blackout and have serious skepticism about the marketing vs. performance and .375 Raptor was cool, but too boutique. After looking across the expanse of the internet, or just asking Google, I found ammo for an acceptable price and also found someone who offers Savage pre-fits chambered in .277 Fury. Here is the resulting rifle.

Action: ARC Nucleus Gen 1 (30 MOA rail, 19lb striker spring)

Tigger: Huber 2-stage

Barrel: McGowen 16.5”, .277 Fury, 1-7”R twist, Savage Pre-Fit, ARC BARLOC

Stock: Manners TA (Altus Highland Camo), Devcon Pillar bedded

Bottom Metal: Badger M5 Enhanced

Scope: Nightforce NX8 2.5-20x50

Rings: ARC

Muzzle: Silencer Co Single Baffle Break

Can: Silencer Co Harvester 300

Total weight: 10lbs (a bit heavier than I wanted)

AMMO: There are current 3x versions of the .277 Fury ammo on the market from Sig. The 132gr Ball (standard case), the 130gr VENARI Soft Point (standard case), and the 150gr Elite Bonded Poly tip (Hybrid case). These all can be found at online vendors and I was able to secure plenty of rounds of the 132gr Ball and 150gr Hybrid for prices that didn’t make me sick to my stomach, or get scammed by some online F’head.

This is where it gets interesting…

As you can see the box velocity for 16in and 24in barrel lengths for both the standard load and higher pressure “hybrid’ load. Box velocity for the 150gr Hybrid case is 2830fps for a 16” barrel and 3120fps for a 24” barrel! That’s outpacing the .270 Win.

The Gen 1 Nucleus is finally at home and feels right in this compact rifle with it’s short stout bolt throw. The rifle is easy pointing and easy to carry, I am very happy with how it all came together.

For the ammo: The 132gr Ball is soft shooting and really pleasing to shoot in the shorty rifle, recoil on par with 6.5 CM or 6.5x47L. The 150gr Hybrid, is definitely spicer in recoil, but not significantly so. In this rifle set up, this doesn’t shoot like my Dad’s old wood stock 30-06’s where after a few rounds you are picking up a subconscious flinch, it is easy like Sunday morning. The ammo performance to barrel length make for a really pleasing Bolt gun.

This is where my testing/scientific method goes to shit as I was out of time and due to the surrounding environment, did not want to shoot without a can on; I was shooting on our property, but harvest was going on the properties adjacent, no need to spook the Pickers, the bullet reports were enough to unsettle them.

When I finally got the Lab Radar to work with the suppressor on the rifle, I had gone through the 132gr Ball ammo I had with me at the table, so no results to report there, which I regret terribly. But….

Yeah, that reads right, 3015fps and 3019fps for the 2 of 5 rounds I could get to record on the Lab Radar (yes, I know this isn’t a complete shot spread SD/ES average so take the SD of 3.2 with a health dose of skepticism). This was WITH the Harvester 300 can ON, which is a long suppressor. However I do not believe that increasing box listed velocity from 2830fps to 3017fps is because of the can, ~50fps sure, but not 187fps.

Here is a look at the primers to show signs of pressure. You can definitely see the pressure signs on the Hybrid case primer.

As I stated in the beginning, not a complete report. I would love to group the gun with this off-the-shelf ammo and then take it out to distance. I will say I love the feel of the rifle with the short barrel and it shoots beautifully. I think the .277 Fury has a lot of potential if people can get over the ”new tech” of it, a 150gr bullet moving at 3015fps out of a 16” barrel is significant. We’ll see if I still have rifling in a 1000 rounds through the barrel, but this isn’t a match gun. For perspective, my 6.8 Western with a 24” barrel shoots 162gr Copper Impacts at 2960fps! That is a short mag cartridge with a lot more powder for like performance. Arguably, the 6.8 Western will probably do better with the heavier +170gr .277 bullets than the .277 Fury Hybrid just due to space for slower burning powders. For now the .277 Fury in this shorty rifle worked out a lot better than I expected.

Take what you want from this report, it’s just raw data.

For my Marine brethren, Crayons and Bourbon is in the corner.

For the Trolls, White Claws and lotion is in the other, do what you want, just don’t look us in the eye.

S/F

Elvis