Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

45ACP

- Thread starter padom

- Start date

Couple here to get it started

Springfield XD 5"

230gr Hornady XTP HP

Win large pistol primer

mixed brass

7.2gr Power Pistol

1.24" OAL

945 FPS

Springfield Range Officer 5"

200gr Xtreme copper plated Semi wad-cutter

Win large pistol primer

mixed brass

6.3gr Unique

1.25" OAL

963 FPS

Springfield XD 5"

230gr Hornady XTP HP

Win large pistol primer

mixed brass

7.2gr Power Pistol

1.24" OAL

945 FPS

Springfield Range Officer 5"

200gr Xtreme copper plated Semi wad-cutter

Win large pistol primer

mixed brass

6.3gr Unique

1.25" OAL

963 FPS

Springfield 1911 Milspec

Nighthawk custom fit match Threaded barrel

Xtreme 230gr Hollow Point

6.2gr N340

CCI LPP

807fps

Nighthawk custom fit match Threaded barrel

Xtreme 230gr Hollow Point

6.2gr N340

CCI LPP

807fps

Berry's 230gr hybrid hp

7.0 cfe pistol

1000 fps? Need to reconfirm but it's stout

7.0 cfe pistol

1000 fps? Need to reconfirm but it's stout

Do you know the O.A.L.?230 gr FMJ

4.2 gr Titegroup

Winchester LPP

Slow and plinky

Nope. I can measure it tomorrow if you’d like. Though they all plunk in a Dillon no-go gauge and cycle through a various name brand 1911 mags and some tight chambers in Kart barrels reamed by a few custom 1911 smiffs.Do you know the O.A.L.?

This has always got my curiosity up when loading ammo for auto-loading handguns.

I have, in the past , just bought factory loaded ammo but in the last few years been hand loading for my 9's and 45's and the question I have is how hot is to hot concerning slide springs

I've also read about frames cracking and +P loads doing damage if fed a diet of +P.

So this thread should be interesting and anyone posting load info on the hot side should also post , if they know, how their particular weapon is setup.

I just went out a tested my 45 load because I had gone past my book max and wanted to see what it was

The load:

230 gr. FMJ

5.6 gr Tite group

OAL 1.260

858 fps.

In two guns, Para Ordnance w/5" barrel and Springfield xds w/3.1" barrel

Both fired over chronograph at about 8'

I have, in the past , just bought factory loaded ammo but in the last few years been hand loading for my 9's and 45's and the question I have is how hot is to hot concerning slide springs

I've also read about frames cracking and +P loads doing damage if fed a diet of +P.

So this thread should be interesting and anyone posting load info on the hot side should also post , if they know, how their particular weapon is setup.

I just went out a tested my 45 load because I had gone past my book max and wanted to see what it was

The load:

230 gr. FMJ

5.6 gr Tite group

OAL 1.260

858 fps.

In two guns, Para Ordnance w/5" barrel and Springfield xds w/3.1" barrel

Both fired over chronograph at about 8'

45 Auto Mixed HS "Reman" Primed Brass - 500ct

45 Auto Mixed HS "Reman" Primed Brass - 500ct

Might interest some of y’all.

230 FMJ

4.2 Clays

4.8 HTG

185 JHP

4.6 N310

5.7 BE-86

These were all 50 yard accurate in my service pistols.

My favorite is 4.6 N310 with a 185 Zero JHP or Hornady XTP or Nosler JHP. OAL of 1.2”. Starline, Winchester, or Federal brass. Winchester Large Pistol primer.

For lead, 3.9-4.0 of Bullseye with a 200 gr lswc. There are plenty of classic bullseye loads online. I can post more if people want. These are some of the most fun loads you can shoot with a 1911.

4.2 Clays

4.8 HTG

185 JHP

4.6 N310

5.7 BE-86

These were all 50 yard accurate in my service pistols.

My favorite is 4.6 N310 with a 185 Zero JHP or Hornady XTP or Nosler JHP. OAL of 1.2”. Starline, Winchester, or Federal brass. Winchester Large Pistol primer.

For lead, 3.9-4.0 of Bullseye with a 200 gr lswc. There are plenty of classic bullseye loads online. I can post more if people want. These are some of the most fun loads you can shoot with a 1911.

I stopped using Berry's years ago after too many blown matches due to malfunctions. Malfunctions I couldn't track down for about two years. Finally figured out that the occasional undersized bullet was hitting the feed ramp and slowing things down just enough for a stoppage. I switched to the double struck ones and it still happened. Then I swore them off.

My general shooting but still easily makes USPSA Major load is 4.2-4.3 grains of Clays and anyone but Berry' s 230gr bullet.

230gr bullet.

For years it was 4.2 grains of Bullseye and any 200-230gr bullet. But Clays smokes less so I switched.

My general shooting but still easily makes USPSA Major load is 4.2-4.3 grains of Clays and anyone but Berry' s

For years it was 4.2 grains of Bullseye and any 200-230gr bullet. But Clays smokes less so I switched.

I stopped using Berry's years ago after too many blown matches due to malfunctions. Malfunctions I couldn't track down for about two years. Finally figured out that the occasional undersized bullet was hitting the feed ramp and slowing things down just enough for a stoppage. I switched to the double struck ones and it still happened. Then I swore them off.

My general shooting but still easily makes USPSA Major load is 4.2-4.3 grains of Clays and anyone but Berry' s230gr bullet.

For years it was 4.2 grains of Bullseye and any 200-230gr bullet. But Clays smokes less so I switched.

When I deviated from " Normal " .45 acp bullets , 165 185 200 225 ,I began experiencing feeding and going into battery problems .

In MY case it was the Idiot behind the press !. I had neglected to adjust the crimp die ,having set it for Std. 230 Gr. RN Ball .

Way way back , I used to set down and load #100's if not K's of rounds in a session ( younger dumber ) only to find out I'd made a serious error regarding case OAL . Not .45 but 7 mm RM !. So from that day forward I reload a magazine or #6 rounds ,walk out back to MY Range and " FUNCTION TEST THEM " before continuing to reload any additional rounds .

After one sits down and pulls 5-10 boxes ( #50 boxes ) of BAD reloads ,it makes you SMARTER , Hopefully

I once ran 900+ rounds of .37 Spl. through a single stange press about four times seating them deeper each time. Stupid. lol

I've an early 70's Colt Gold Cup and an 80's Officers ACP, they care about OAL. When I started shooting a bunch of SIG P220's and a 245, they didn't seem to care as long as they fit in the magazine. When I eventually went back to shooting the Officer's model again I had issue. "Oh yeah... I forgot this matters."

But really I think it's just my Colts. I load for 7-8 other 45 ACP semi autos and they really don't seem to care. Though I don't think any of them have ever seen a 185gr semi wadcutter.

I've an early 70's Colt Gold Cup and an 80's Officers ACP, they care about OAL. When I started shooting a bunch of SIG P220's and a 245, they didn't seem to care as long as they fit in the magazine. When I eventually went back to shooting the Officer's model again I had issue. "Oh yeah... I forgot this matters."

But really I think it's just my Colts. I load for 7-8 other 45 ACP semi autos and they really don't seem to care. Though I don't think any of them have ever seen a 185gr semi wadcutter.

My Springfield RO SS 5" Target has yet to see a round ,still NIB and I bought it in 90's .

My Colt government 5" and Griffon 5" Combat digest nearly anything but that Nice little Commander carry model was reworked by it's former owner . Retired Gunny Dave Ransberger ( RIP ) ,used to own Cal Customs a LGS in a small town of Fallbrook , CA. not far from back gates of Camp Pendelton Marine Corp base . Knew and dealt with him for decades ,as I did with other long time established LGS owners in SoCal back in the days . Make em right just not too tight

My Colt government 5" and Griffon 5" Combat digest nearly anything but that Nice little Commander carry model was reworked by it's former owner . Retired Gunny Dave Ransberger ( RIP ) ,used to own Cal Customs a LGS in a small town of Fallbrook , CA. not far from back gates of Camp Pendelton Marine Corp base . Knew and dealt with him for decades ,as I did with other long time established LGS owners in SoCal back in the days . Make em right just not too tight

Has anybody seen small primer .45ACP brass? I was going through a coffee can of brass the other day and came across some of these. They're just range pickups so I have no idea how they shot. Does anyone have load data for small pistol primer .45?

I was loading 185gr Hornady XTP

w/ 6.2gr Titegroup

w/WLP Primers to OL of 1.20"

I have not crony'd them but Horndady book says 1,000 fps

They shoot well in my STI Lawman 5"

I was loading 185gr Hornady XTP

w/ 6.2gr Titegroup

w/WLP Primers to OL of 1.20"

I have not crony'd them but Horndady book says 1,000 fps

They shoot well in my STI Lawman 5"

Yep. Pretty sure S&B is all SPP. Found that out the hard way. Went cross-eyed sorting through a 5 gal bucket of cleaned range pickup .45.Has anybody seen small primer .45ACP brass? I was going through a coffee can of brass the other day and came across some of these. They're just range pickups so I have no idea how they shot. Does anyone have load data for small pistol primer .45?

I was loading 185gr Hornady XTP

w/ 6.2gr Titegroup

w/WLP Primers to OL of 1.20"

I have not crony'd them but Horndady book says 1,000 fps

They shoot well in my STI Lawman 5"

For spp increase powder by about 0.1 or 0.2 gr to get same velocity as your lpp load.Has anybody seen small primer .45ACP brass? I was going through a coffee can of brass the other day and came across some of these. They're just range pickups so I have no idea how they shot. Does anyone have load data for small pistol primer .45?

I was loading 185gr Hornady XTP

w/ 6.2gr Titegroup

w/WLP Primers to OL of 1.20"

I have not crony'd them but Horndady book says 1,000 fps

They shoot well in my STI Lawman 5"

I recently cleaned around 2500 .45 cases ,found no less than #22 different head stamps and not a single small primer pocket . All including Foreign cases LPP . Years 50's-2016 . Not a single aluminum or steel case either , normally something odd shows up but in this series, only #2 , 9mm's were mixed in . I've ceased to use SS pin tumbling any longer ,as MY Ultrasonic cleaner with My solution recipe is far superior and so much faster . Example .45 Cal , 3.5 minutes in Ultrasonic verses 2+ hr. pin tumbling ,with less than desired results .

Attachments

So…what’s the secret sauce for the ultrasonic cleaner? Give it up!

This one may be spoken for ,as I submitted samples for formulation production sales . I'm a retired PhD. Chemist and I formulated this one from scratch .

I will say it's acidic based ,so full flushing or neutralization rinse is highly recommended .

I have used a hot water weaker citric acid solution on suppressed brass for about 30-45 minutes with some success, but it seems to ‘etch’ the brass a bit. Be interesting to see how you get it done in 3.5 minutes without hitting the brass too hard.

So what you can't tell what it is?????This one may be spoken for ,as I submitted samples for formulation production sales . I'm a retired PhD. Chemist and I formulated this one from scratch .

I will say it's acidic based ,so full flushing or neutralization rinse is highly recommended .

I've come across maybe a dozen spp since starting to reload and it always happens when I'm in a groove. I had 2 in the last 100 I was working on. Loaded them all with 4.6gr of Titegroup under 230gr pills and my Tisas loved them.

I have used a hot water weaker citric acid solution on suppressed brass for about 30-45 minutes with some success, but it seems to ‘etch’ the brass a bit. Be interesting to see how you get it done in 3.5 minutes without hitting the brass too hard.

So what you can't tell what it is?????

Brass becomes contaminated with Carbon and fusible gas by product ,so the object is to Clean it as efficiently as possible .

HOT water doesn't have to be boiling but temp above 140 Deg. F is Helpful . I make mine 160-170 F.

I prefer commercial Citric acid based cleaners , if one is using acid be sure it's Citric or Vinegar ( acetic acid ) . 4-8% Bottled vinegar is Normal .

It Doesn't require a great deal of acid ,so DON'T go nuts or too long ,otherwise you get Pickled Pink Brass .aka dezincification

Detergents are best for oils ( fingers and gun oil contaminate brass surfaces ) ,so Good ones are Dawn dish soap ,Lemishine if using this cut down amount of acid added too water . I have seen Good results using Orange Lemon based detergents as well aka citric acid .

Typical Gallon solution would be # 2 tbsp or 30.0mL detergent ,#2-3 tbsp acid ,so 30.0- 45.0 mL , Also Borax can be added # 2 tbsp - 30.0 mL .

You can also SAVE the solution by way of filtration ( remove the sediment crud via ceramic or paper coffee filter and funnel ) and use it over and over .

Fyi : This formula works for Ultrasonic ** as well as Pin polishing . IF pin polishing cut or add half clean water to the formula and DON'T HEAT the water . BAD things happen tumbling with heated water .

** There are Different grades as well as frequencies of Ultrasonic cleaners . I use a commercial grade #3 frequency 35 kHz ,55 kHz and 128 kHz ,known as a #3 cycle generator . It cleans FASTER ,as well as Better .

There are also Megasonic generators and generally operate above 350 kHz and beyond 1.5MHz .

The Best advice I can bestow is ; PRE CLEAN Your Brass . #5 gallon bucket , a little Dawn ,Borax dissolved in HOT HOT water and allow to stand 15min. to 1 hour ,agitate bucket #8-10 times and add enough water to Cover cases ,NO more than necessary . Don't bother rinsing IF You're gonna ultrasonic or pin polish afterwards . After ultrasonic or pin polishing , RINSE WELL in clean water ; I use de- ionized as I make it .

I have used a hot water weaker citric acid solution on suppressed brass for about 30-45 minutes with some success, but it seems to ‘etch’ the brass a bit. Be interesting to see how you get it done in 3.5 minutes without hitting the brass too hard.

I , like many of us use a universal de-capper to de-prime cases . After I initially clean MY brass one time ,I do the following after shooting .

I'll run the brass in the universal de-capper pop spent primers ,then place all My cases in a Anchor Hocking bread loaf dish ,set into a bath of de-ionized water . I then pour My cleaning solution directly into the glassware dish with cases in it . I've already preset the heating cycle of the bath water . I ensure the water level is near full ,without either contaminating the other . So solution and cases glass dish is full ,as is the surround water . Turn on unit ( now ) with preset timer 3:30 minutes . End of cycle drain clean bath water ,into a 2.5 gal. plastic jug , I then remove glass dish drain while straining solution . Rinse cases thoroughly put them into My Dillon media separation hopper and lock it ,flip the motor on and around and around the cases flop ,not allowing water to set and drying at same time . As I've yet to build the force dryer ,I'm using a 16" #3 speed fan on #2 setting and it blows directly onto cases . Takes about 20-30 minutes for complete drying .

IF I'm gonna run cases and restore ductility via My modified Annealeez ,I'll cut drying short by 10-15 minutes .

Sometimes IF I want Pretty cases ,I'll either rerun the ultrasonic or simply pin tumble ,so as to remove most if not all the witness marks .

I introduce ductility ( what many refer to as annealing ) after every #3 firing on bottle neck cases .

I'm happy to report I've as of Yesterday gotten #29 firings on 1942-68 LC .30 Cal. cases and I load near top end . Haven't lost a single case nor tore any rims and if anyone has Garands they know that's remarkable in itself . As we all know Gas Guns aren't the most forgiving extractors .

Those original once fired cases had set too the weather for 45-50 + years before I got hold of them and were UGLY ,as in triple bagger UGLY !.

I must have measured perhaps #250 New Lapua cases in various calibers and found something interesting ,from the case mouth south the witness mark is 0.591 down the shoulder towards the body . Once I started duplicating that heat signature , MY cases began sealing as well as lasting longer . Restoring the neck & shoulder ductility most certainly lessons carbon neck shoulder ring as well as gives pretty consistent velocity . So knowing a little more than the average person ,due in large part to Norma . I believe the secret is NOW revealed as to Lapua's Case success .

Fyi: I found by changing frequency of the ultrasonic ,I was able to clean even the rebated rim groove substantially better ,thus giving desired quick cleaning results .

Attachments

What bad things happen? I always pin tumble with as hot of water as I can get. 30 minutes and then rinse.BAD things happen tumbling with heated water .

What bad things happen? I always pin tumble with as hot of water as I can get. 30 minutes and then rinse.

Heat produces pressure as does tumbling which magnifies it and generally speaking liquid soap aided by Non-ionic surfactants ,slips by the rubber sealing gasket . From the limited # of roto-molded polishing drums ,I've seen for reloaders ,their rubber gasket and coarse screw lids aren't the best for pressure vessels . IMO .

Heat produces pressure as does tumbling which magnifies it and generally speaking liquid soap aided by Non-ionic surfactants ,slips by the rubber sealing gasket . From the limited # of roto-molded polishing drums ,I've seen for reloaders ,their rubber gasket and coarse screw lids aren't the best for pressure vessels . IMO .

Yea no.....

With my Rebel rotary I use water warmer than the room temperature. If I use water colder than the room the drum seal will weep until the temps equalize.

I don't understand the science of it but another member wrote about how this works. Ever since I learned this trick no more weeping.

I don't understand the science of it but another member wrote about how this works. Ever since I learned this trick no more weeping.

Favorite .45 ACP reloads:

1.) 4.6/RedDot (or Promo)/230 gr. 230 gr. LEE TC, 800 + 25 f/s

2.) 6.5-7.0/Unique/215 gr. SAECO #58 215 gr. LSWC-PC (same bullet in BOBKE's post #31 on this thread, but polymer coated), 870 + 20 f/s

3.) 7.3/BE-86/200 gr. LSWC, 1073 + 8 (!!!) f/s. (HUNTING LOAD, HOT!!! Work up from 6.5/Unique)

The first load is my practice/competition load, but would certainly work for EDC purposes. The second load IS my EDC load, and tends to penetrate better. The third was my hunting load in .45 ACP, before I obtained my .45 Colt Redhawk. I took a good-sized Oklahoma Whitetail with it at 47 measured steps. The animal bolted a few steps and crumpled.

All these loads were clocked from a 5" SA 1911A1 National Match, with a chronograph 8' from the muzzle. The third load was chronographed with the same pistol, equipped with a shok-buff, higher rate slide spring and a flat-based firing pin stop in place.

Brass cleaning: The least troublesome method I'VE found is to put brass in an empty gallon milk container, up to about halfway (less than this is fine), and add a teaspoon of cream of tartar, and a teaspoon of DAWN dishwashing soap. Add hot tap water to slightly above the level of the to-be-cleaned brass (I use the width of my thumb as a "measure"). Cap the jug and shake it by the integral handle for 30 seconds, then let set. Repeat shaking 2 or more times (or until you get tired of it), then let set for 10-15 minutes.

Rinse three times with cold tap water (filling the jug to the top helps, here), and empty brass onto a bath towel that nobody cares about.

Probably not all of the brass will come out looking factory-shiny, but a majority should.

Repeating the process, omitting the dish soap and using citric acid or vinegar may "shine up" the remainder of the brass. Just repeating the above-described process and letting the more dingey brass set overnight has also worked for me. I recall no "etching" from the cream of tartar (sodium tartrate) when doing this.

One may eventually end up with a handful or two of brass that will not get shiny without tumbling, but the amount should be smaller and more manageable after the treatment I describe.

1.) 4.6/RedDot (or Promo)/230 gr. 230 gr. LEE TC, 800 + 25 f/s

2.) 6.5-7.0/Unique/215 gr. SAECO #58 215 gr. LSWC-PC (same bullet in BOBKE's post #31 on this thread, but polymer coated), 870 + 20 f/s

3.) 7.3/BE-86/200 gr. LSWC, 1073 + 8 (!!!) f/s. (HUNTING LOAD, HOT!!! Work up from 6.5/Unique)

The first load is my practice/competition load, but would certainly work for EDC purposes. The second load IS my EDC load, and tends to penetrate better. The third was my hunting load in .45 ACP, before I obtained my .45 Colt Redhawk. I took a good-sized Oklahoma Whitetail with it at 47 measured steps. The animal bolted a few steps and crumpled.

All these loads were clocked from a 5" SA 1911A1 National Match, with a chronograph 8' from the muzzle. The third load was chronographed with the same pistol, equipped with a shok-buff, higher rate slide spring and a flat-based firing pin stop in place.

Brass cleaning: The least troublesome method I'VE found is to put brass in an empty gallon milk container, up to about halfway (less than this is fine), and add a teaspoon of cream of tartar, and a teaspoon of DAWN dishwashing soap. Add hot tap water to slightly above the level of the to-be-cleaned brass (I use the width of my thumb as a "measure"). Cap the jug and shake it by the integral handle for 30 seconds, then let set. Repeat shaking 2 or more times (or until you get tired of it), then let set for 10-15 minutes.

Rinse three times with cold tap water (filling the jug to the top helps, here), and empty brass onto a bath towel that nobody cares about.

Probably not all of the brass will come out looking factory-shiny, but a majority should.

Repeating the process, omitting the dish soap and using citric acid or vinegar may "shine up" the remainder of the brass. Just repeating the above-described process and letting the more dingey brass set overnight has also worked for me. I recall no "etching" from the cream of tartar (sodium tartrate) when doing this.

One may eventually end up with a handful or two of brass that will not get shiny without tumbling, but the amount should be smaller and more manageable after the treatment I describe.

Last edited:

Anyone loading Lyman 452460 LSWC for 1911?? Lyman manual calls for a coal of 1.161 which is WAY short... it actually starts curling in the case mouth that short..

Every report I see online everyone is loading these in the 1.20-1.25 range.

Anyone loading or have Loaded these and what's your coal???

Every report I see online everyone is loading these in the 1.20-1.25 range.

Anyone loading or have Loaded these and what's your coal???

What kind of length do you get when you seat these bullets so that the driving band is ~1/32" above the case mouth? Invariably, when I use SWCs in .45 ACP, that ends up being o.a.l. that works best for me.

I'm not wondering what works best. I'm asking if anyone has this issue seating these bullets to Lyman manual suggested coal of 1.161"..

I'll tweak seating depth to whatever my gun likes during my load development. Just find this lyman manual suggested coal very short that's why I asked

I'll tweak seating depth to whatever my gun likes during my load development. Just find this lyman manual suggested coal very short that's why I asked

I've never used that projectile, so I'm no help. I will admit that the suggested OAL is a head scratcher. I wonder if it's a typo or an entry error. Could the suggested OAL be 1.261"?

5.8 to 6.0 grains of Unique under any 230 grain projectile works magic for me

Back when dirt and I were young, my first reloading apparatus was a Lee classic loader. The scoop included with it threw 5.8/Unique or very close to it. 5.8/Unique/230 gr. TC was a wonderful load for me, though in some pieces it would not comfortably make "Major". As can also be expected with Unique, it seemed to burn a bit more dirty than was necessary. 6.0/Unique/230 gr. ALWAYS made "Major", with no loss of accuracy, negligible change in control, and far less time spent cleaning brass.5.8 to 6.0 grains of Unique under any 230 grain projectile works magic for me

I also discovered that 5.8/Unique/255 gr. Speer LSWC made a superb load for bowling pins competitions. It might have been a bit more powerful than was really needed, but it certainly made the pins clear the table when I did MY part.

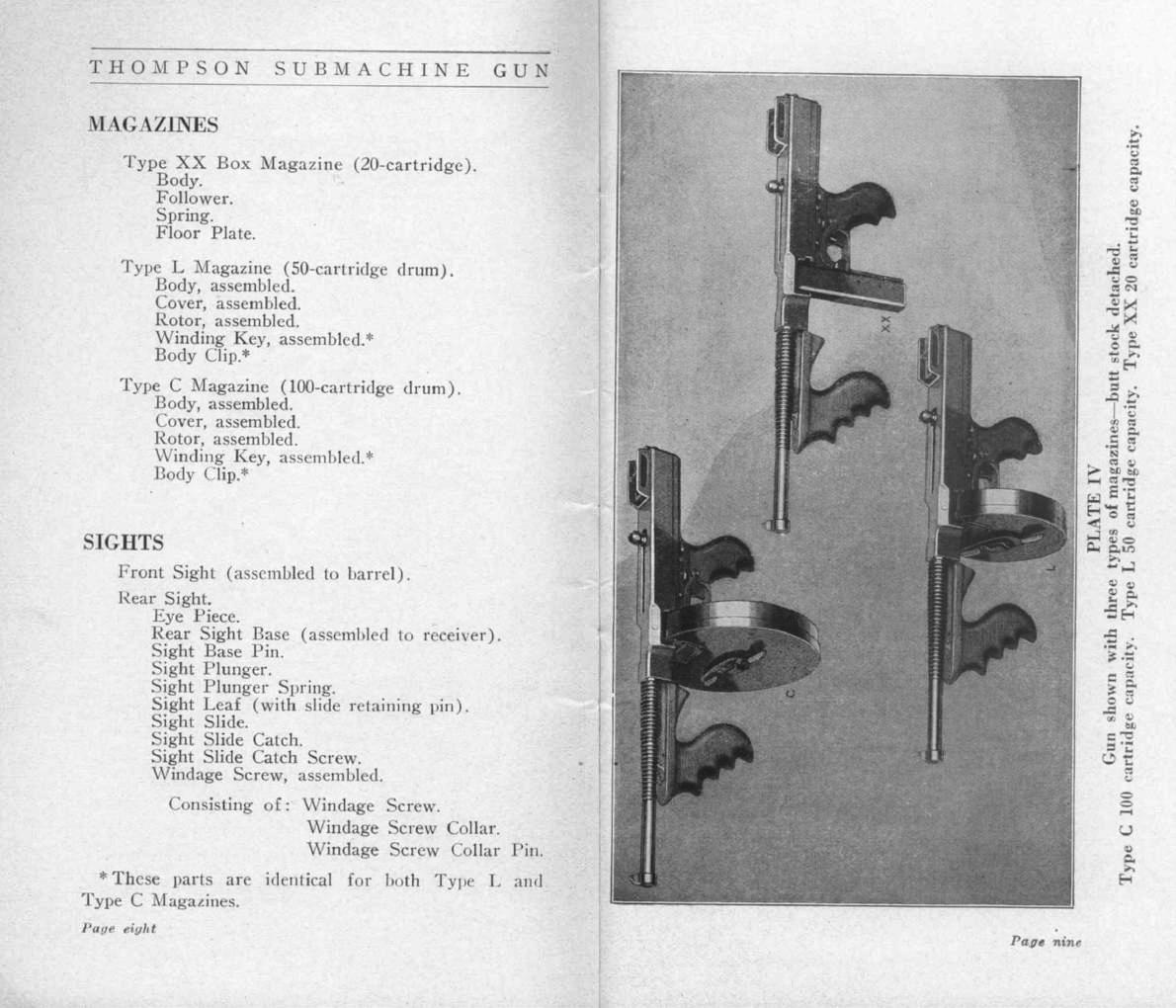

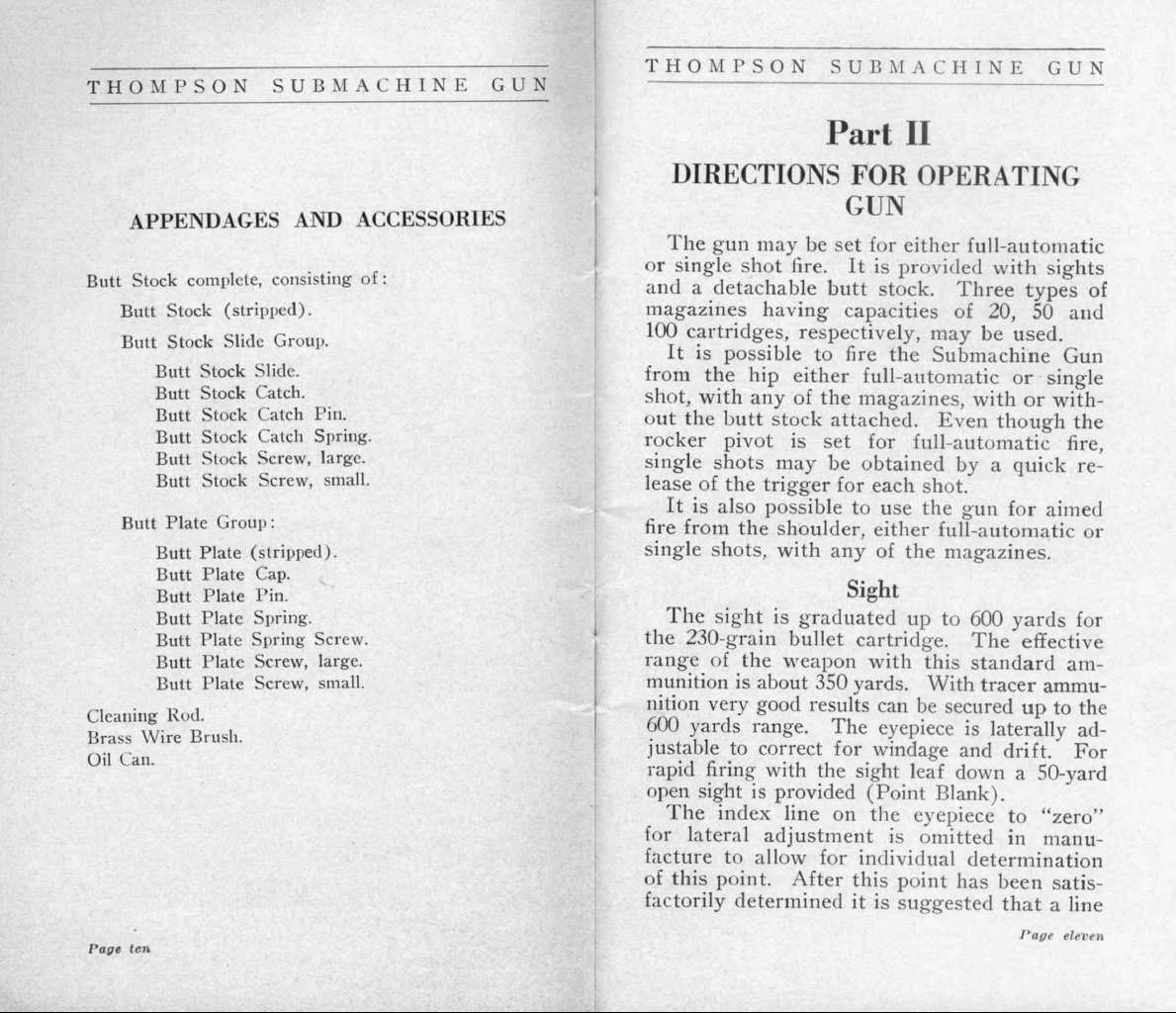

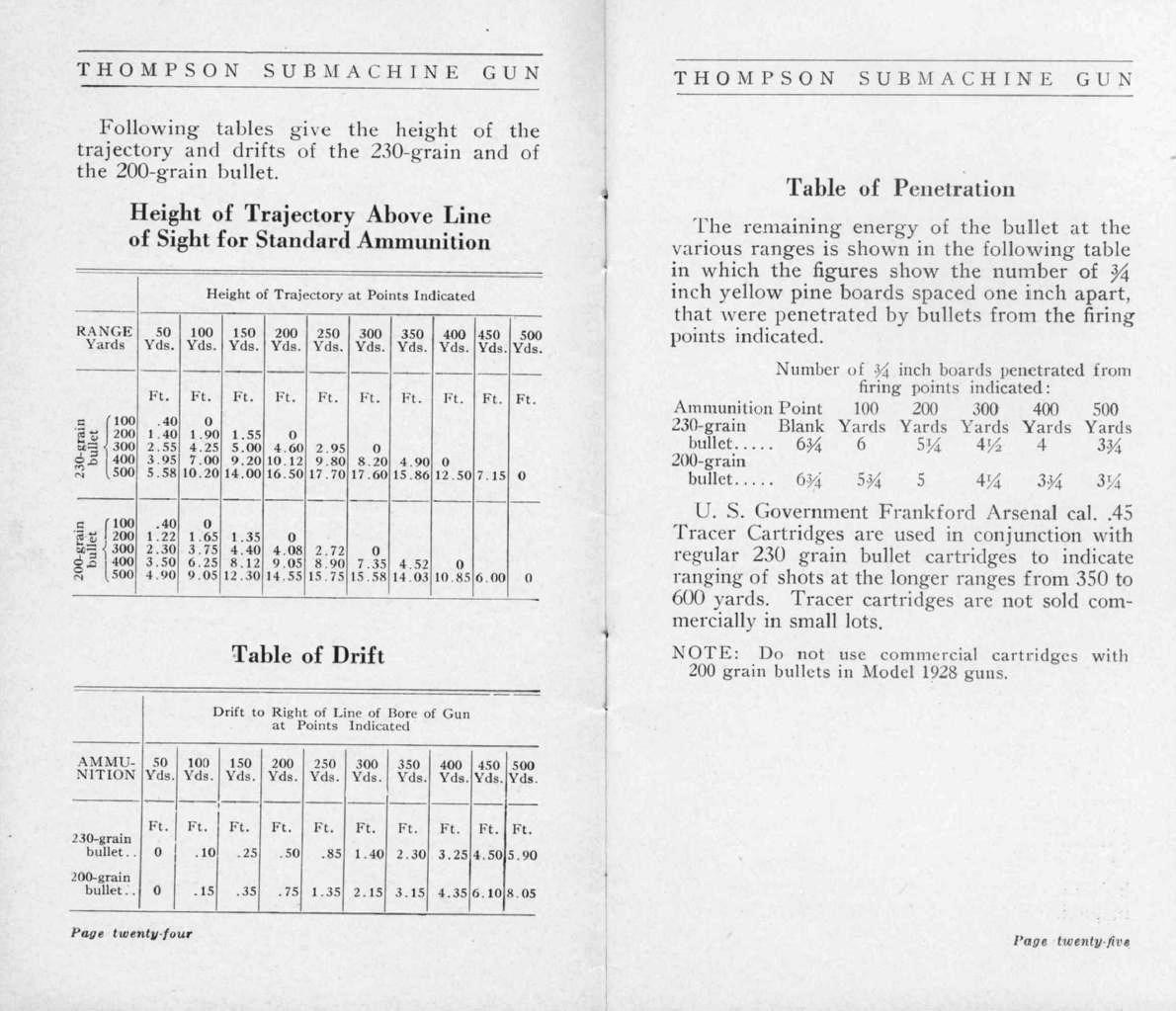

Ballistics for standard 200 gr and 230 gr military balls fired from Tommy gun (original manual from 1929):

With a .45 Acp pistol Colt Gov. model zeroed at 25Yd. using a 230 gr. bullet ,the trajectory drop would be 14.8" at 100 Yd. right ?

Said bullet penetrates 3" of wood at 500 Yd. ,maybe balsa wood . There's Not enough energy left to penetrate 2" of wood IMO .

Highly doubtful I could even hit a piece of wood at 500 Yd. using MY .45's . Mine are OK from 0-75 yd. but after that I'd be praying ,not much of a sight radius on 5" ,let alone holdover reference . Of course I Don't own a Thompson either !.

Said bullet penetrates 3" of wood at 500 Yd. ,maybe balsa wood . There's Not enough energy left to penetrate 2" of wood IMO .

Highly doubtful I could even hit a piece of wood at 500 Yd. using MY .45's . Mine are OK from 0-75 yd. but after that I'd be praying ,not much of a sight radius on 5" ,let alone holdover reference . Of course I Don't own a Thompson either !.

Military used to use 3/4" thick boards made of soft pine (separated by 1" gaps) for the penetration tests. Thus 3.75"*0.75 ≈ 2.8" at 500 yards according to their data. Interesting, the trajectory tables data (above up to 500yd) are obtained/confirmed by series of actual firing tests, and not just calculated.

Zero 230gr FMJ

5grs WST

WLP

1.275” COAL

775 FPS average from a 5” SA Custom Shop 1911.

Soft recoil, cycles nice with a 16lb spring. Shoots half-inch at 15 yards from a rest. It is important to keep the coal long because if you shorten it lower than 1.270” then groups open up.

5grs WST

WLP

1.275” COAL

775 FPS average from a 5” SA Custom Shop 1911.

Soft recoil, cycles nice with a 16lb spring. Shoots half-inch at 15 yards from a rest. It is important to keep the coal long because if you shorten it lower than 1.270” then groups open up.

Similar threads

Reloading Equipment

Dillon 650/750 Caliber Conversions

- Replies

- 1

- Views

- 89

Reloading Equipment

WTS: Hornady Custom and DAA Seater / Crimp dies

- Replies

- 2

- Views

- 92

Reloading Equipment

Dillon 650xl with extras

- Replies

- 10

- Views

- 775