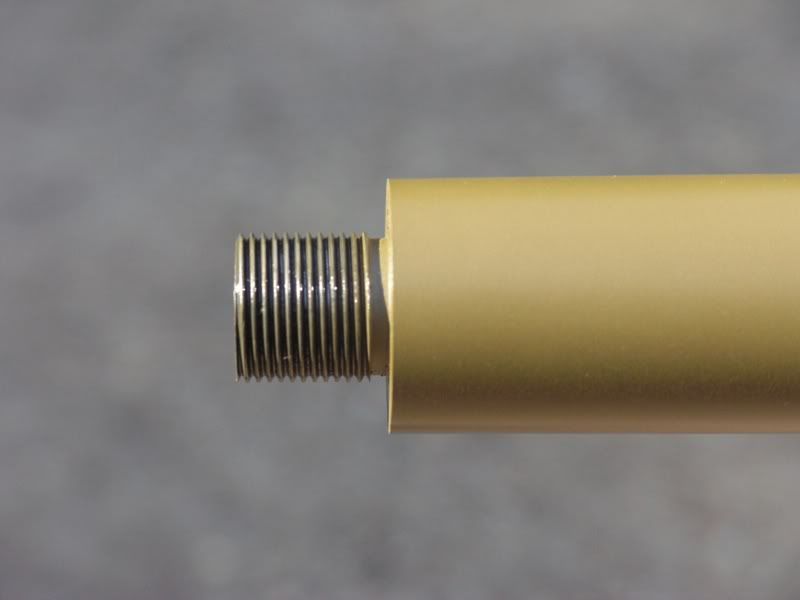

Sorry for the long story but.......I need some advice, I bought a supressor and I'm waiting on the paperwork, I don't want to start a debate so I won't mention the brand, it is a direct thread .30 cal can. I took my rifle to the dealer to test fit the can. The can would thread on about halfway and stop. My buddy's can (different brand) did the same thing. I did not want to damage the threads on the can so I did not force it. I read the company's website info they advise the 5/8 x 24 threads need to be .625 in diameter (the total diameter of the tops of the threads. The threads on my rifle measure .627

I talked to the gunsmith who threaded my barrel, he was strongly recommended here on the hide. His advice was to use "never seez" and work the muzzle device back and forth until it fit. I certainly dont want to damage the can and or the threads on my rifle. The Ops inc brake he installed, 5/8 x 24 fits perfectly, but the yankee hill thread protector i bought, also 5/8 x 24 wont even thread on one turn. What do I do? Any gunsmiths out there please chime in. Would running a 5/8 x 24 die on my threads cut the tops down to size? My buddy said I could sand the tops down but that seems risky... any advise would be appreciated.

I talked to the gunsmith who threaded my barrel, he was strongly recommended here on the hide. His advice was to use "never seez" and work the muzzle device back and forth until it fit. I certainly dont want to damage the can and or the threads on my rifle. The Ops inc brake he installed, 5/8 x 24 fits perfectly, but the yankee hill thread protector i bought, also 5/8 x 24 wont even thread on one turn. What do I do? Any gunsmiths out there please chime in. Would running a 5/8 x 24 die on my threads cut the tops down to size? My buddy said I could sand the tops down but that seems risky... any advise would be appreciated.