All,

So this is the 2nd round of me trying to develop a decent load for my Daniel Defense DD5v5 20" AR-10. The 2nd round rendered a significant improvement in tighter groupings over the 1st round of development. Unfortunately, I did run into some issues that I need some advice on. Before addressing the details of this 2nd round of load development and its issues, below are the details concerning my 1st attempt during the week previously:

1st Attempt was Document Here:

https://www.snipershide.com/shootin...y-1st-6-5cm-load-development-results.7019204/

Lessons Learned from 1st Attempt:

-Increment your loads by .2-.3 grains for each string (I previously made too big of a jump)

-Don't use the Magnetospeed when testing for accuracy, but only for testing velocity

-allow the barrel to cool down significantly between strings

2nd Attempt

The goal of this session was to bring the lessons learned from the 1st attempt and grab better data for load development.

-Ladder load test by .2 grains for each increment using RE17 from 38.0 grains to 41.2grains

-Again shooting 140gr SMK bullets

-WLR primers

-Range temperature was about 74 degrees.

-Shooting 3 rounds per string at a range of 100 yards

-Used Magnetospeed to gather 1 shot velocity reading, provided that the 4th round loaded for the given charge wasn't used to compensate for a flier shot.

-Used "The Original Barrel Cooler" once the barrel became too hot to the touch. This was usually done between each string in most case, but only done as needed.

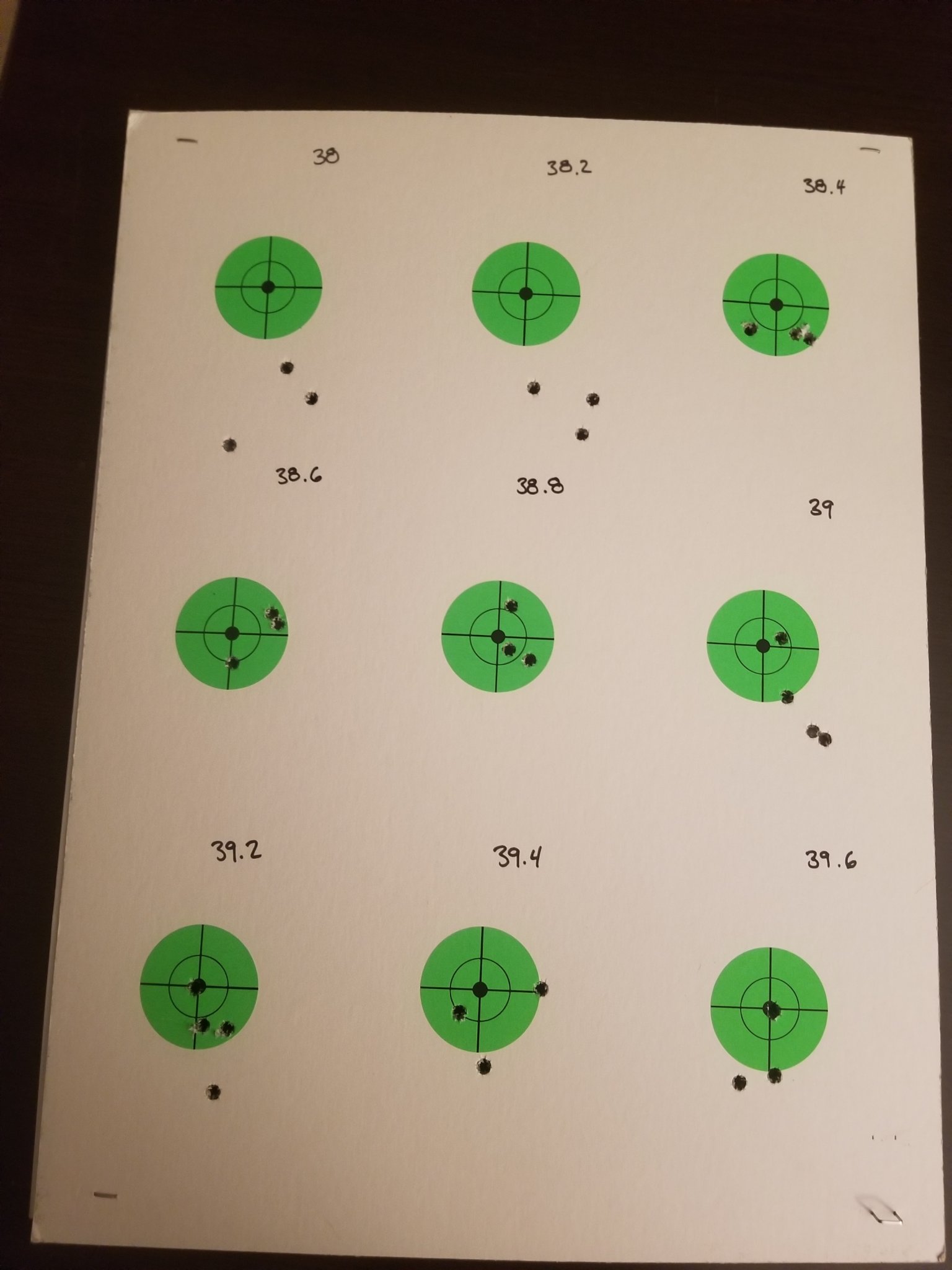

Shot Groups:

(sorry no measurements posted yet, the green target sticker is 2". I'll post update measurements tonight with fliers x'd out)

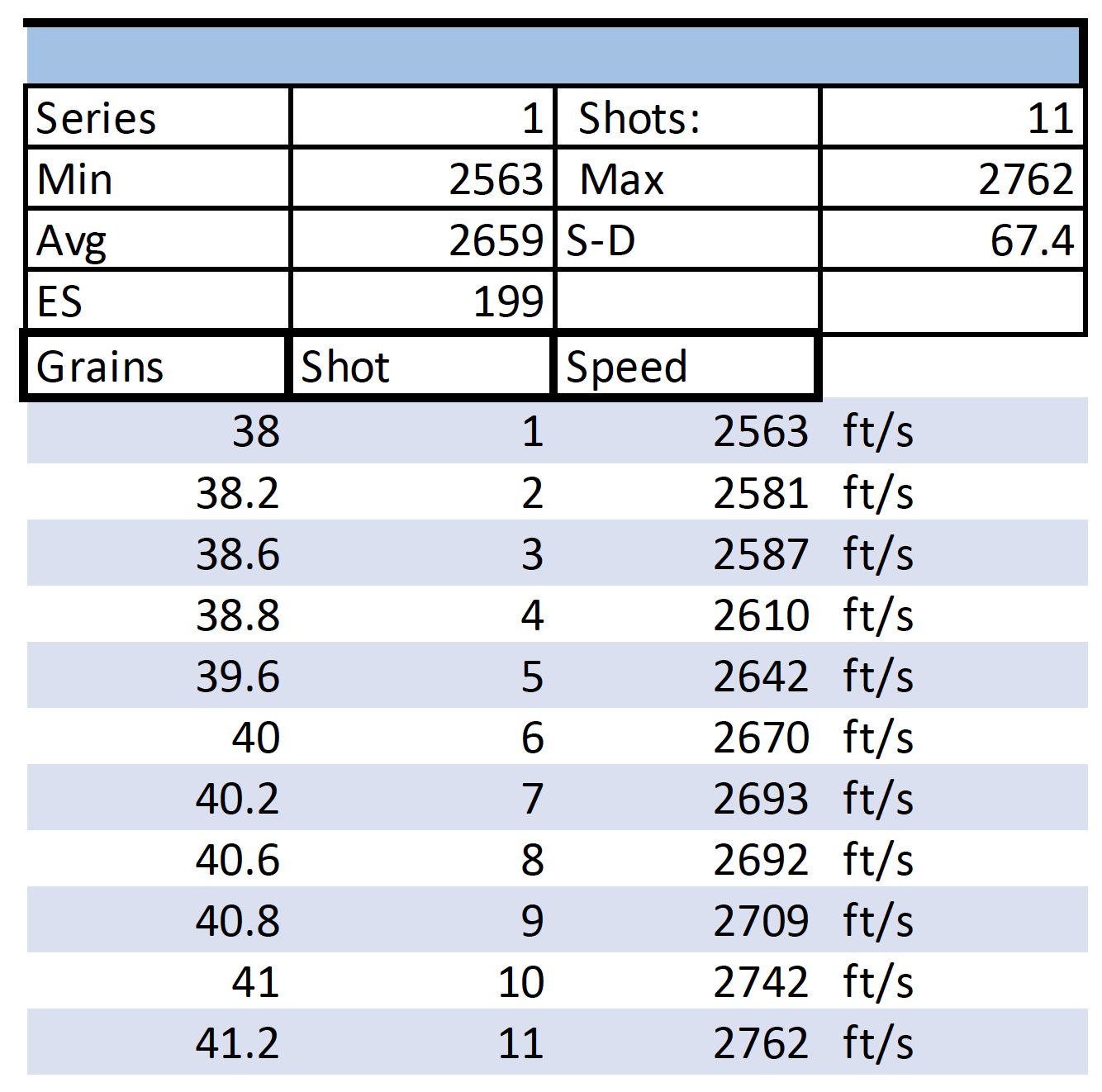

Chrono Data:

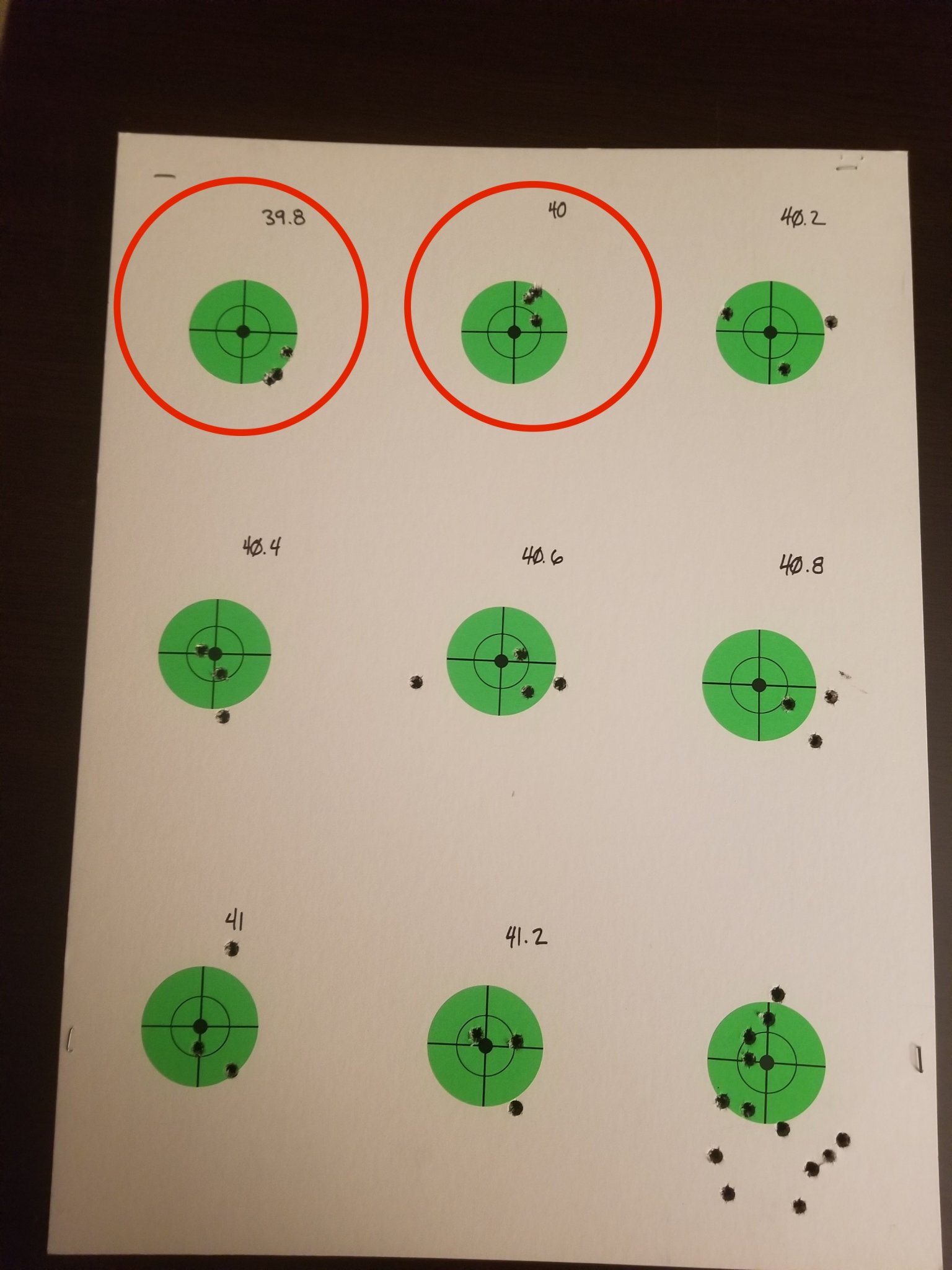

I chose to identify 39.8 and 40 grains as shooting the tightest groups

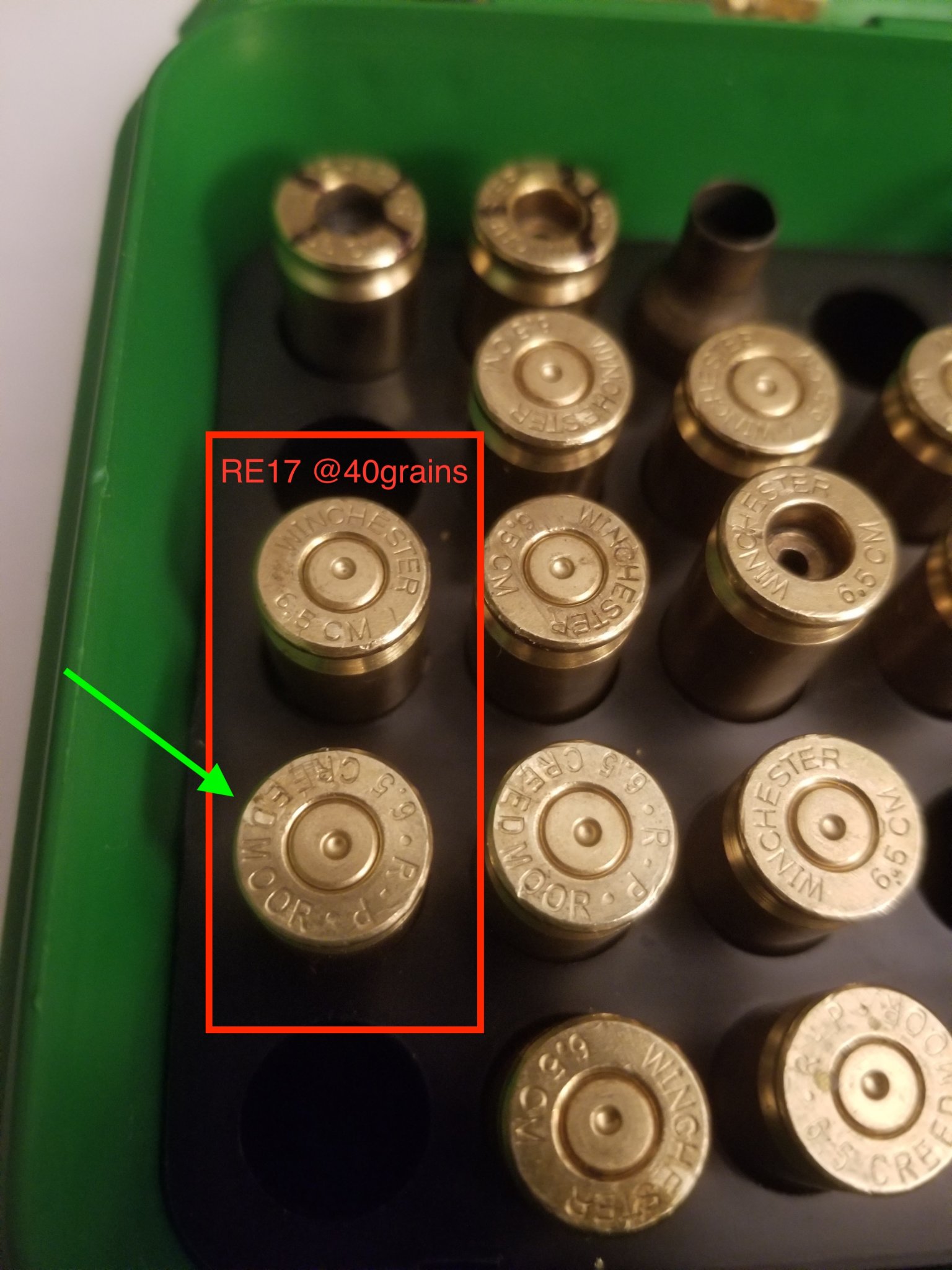

Condition of Brass from Tight Groups:

**Green arrow is pointing to some ejector pin marks noted**

**Green arrow is pointing to some ejector pin marks noted**

**Green arrow is pointing to some ejector pin marks noted**

**Green arrow is pointing to some ejector pin marks noted**

**Green arrow is pointing to some ejector pin marks noted**

**Green arrow is pointing to some ejector pin marks noted**

As mentioned above, I identified the RE17 charge of 39.8-40grains giving the tightest groupings. I am having difficulty making a judgement call on the pressure indicators of the spent brass at those charges. I have identified some ejector pin rub marks. At the same time though, the WLR primers aren't appearing flatten nor are there signs of cratering around the firing pin. What should I make of these pressure signs? The Magnetospeed is clocking the velocity of these rounds at approx. 2650-2670fps, which doesn't sound like I'm really pushing it.

Issues During Range Visit:

Unfortunately, I developed a new issue during this 2nd attempt range, and oddly enough it didn't occur during my 1st attempt. I experienced 3 rounds fail to chamber correctly. The rounds appeared make it most of the way out of the magazine and wedged themselves somewhere between the barrel extension and the chamber. The BCG completely smashed these rounds, in some cases, causing the primers to pop out. Below are some of the examples of the aftermath:

After measuring my my max COL after fitting my handholds into the AR-10 P-mags, I noted that it was less than the max COL as noted in my two reloading manuals. I did decide to come back a few thousandths from the max COL as allowed from my magazine. What could be causing this issue and where should I look? I will provide the specific measurements later tonight, as they are in my reloading record book at home. I personally feel that it might be an issue related to length, but I'm not experienced enough to be certain. All my brass was full-length resized -.003 from fire-formed.

Thanks for any and all help that you can provide!

So this is the 2nd round of me trying to develop a decent load for my Daniel Defense DD5v5 20" AR-10. The 2nd round rendered a significant improvement in tighter groupings over the 1st round of development. Unfortunately, I did run into some issues that I need some advice on. Before addressing the details of this 2nd round of load development and its issues, below are the details concerning my 1st attempt during the week previously:

1st Attempt was Document Here:

https://www.snipershide.com/shootin...y-1st-6-5cm-load-development-results.7019204/

Lessons Learned from 1st Attempt:

-Increment your loads by .2-.3 grains for each string (I previously made too big of a jump)

-Don't use the Magnetospeed when testing for accuracy, but only for testing velocity

-allow the barrel to cool down significantly between strings

2nd Attempt

The goal of this session was to bring the lessons learned from the 1st attempt and grab better data for load development.

-Ladder load test by .2 grains for each increment using RE17 from 38.0 grains to 41.2grains

-Again shooting 140gr SMK bullets

-WLR primers

-Range temperature was about 74 degrees.

-Shooting 3 rounds per string at a range of 100 yards

-Used Magnetospeed to gather 1 shot velocity reading, provided that the 4th round loaded for the given charge wasn't used to compensate for a flier shot.

-Used "The Original Barrel Cooler" once the barrel became too hot to the touch. This was usually done between each string in most case, but only done as needed.

Shot Groups:

(sorry no measurements posted yet, the green target sticker is 2". I'll post update measurements tonight with fliers x'd out)

Chrono Data:

I chose to identify 39.8 and 40 grains as shooting the tightest groups

Condition of Brass from Tight Groups:

As mentioned above, I identified the RE17 charge of 39.8-40grains giving the tightest groupings. I am having difficulty making a judgement call on the pressure indicators of the spent brass at those charges. I have identified some ejector pin rub marks. At the same time though, the WLR primers aren't appearing flatten nor are there signs of cratering around the firing pin. What should I make of these pressure signs? The Magnetospeed is clocking the velocity of these rounds at approx. 2650-2670fps, which doesn't sound like I'm really pushing it.

Issues During Range Visit:

Unfortunately, I developed a new issue during this 2nd attempt range, and oddly enough it didn't occur during my 1st attempt. I experienced 3 rounds fail to chamber correctly. The rounds appeared make it most of the way out of the magazine and wedged themselves somewhere between the barrel extension and the chamber. The BCG completely smashed these rounds, in some cases, causing the primers to pop out. Below are some of the examples of the aftermath:

After measuring my my max COL after fitting my handholds into the AR-10 P-mags, I noted that it was less than the max COL as noted in my two reloading manuals. I did decide to come back a few thousandths from the max COL as allowed from my magazine. What could be causing this issue and where should I look? I will provide the specific measurements later tonight, as they are in my reloading record book at home. I personally feel that it might be an issue related to length, but I'm not experienced enough to be certain. All my brass was full-length resized -.003 from fire-formed.

Thanks for any and all help that you can provide!

Attachments

Last edited: