Just got me a new Proof SS barrel in 6 Dasher all mounted up this past week. The brass i have for it is used and has actually been used in 2 other barrels. In preparation for the new barrel I bought a ring sizer die to whip the head/web area into shape. The rounds chamber fine, no resistance to speak of. I can load and eject the rounds just fine. When they are fired they will absolutely not come out of the chamber. I fired 15 shots and had to use a cleaning rod to gently tap each one out. Stuck enough that it was taking shavings off the rim if I pulled the bolt enough. Brass doesn't have any obvious markings on it. Not sure where to go next.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Online Training Rescheduled: Join Us Next Week And Get 25% Off Access

Use code FRIDAY25 and SATURDAY25 to get 25% off access to Frank’s online training. Want a better deal? Subscribe to get 50% off.

Get Access Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6 Dasher stuck case issue

- Thread starter jsimonh

- Start date

You able to measure sized vs fired dimensions at the .200 line with the new chamber? Just wondering if that ring die got it enough.

Getting your hands on a piece of new brass would be another good test to see if it was the old brass causing the issue or perhaps something in the chamber (though you did check for marks on the brass).

Getting your hands on a piece of new brass would be another good test to see if it was the old brass causing the issue or perhaps something in the chamber (though you did check for marks on the brass).

So the area you asked about is .468 on both fired and resized brass. About .1 below the shoulder neck junction the fired stuff measures .460 and the unfired stuff measures .457. Cases are all the same length and measure right at 1.541. I dont have any new brass but I did have some just once fired brass that I've just had laying around and tried a couple of pieces of them with basically the same result. The once fired stuff wasn't sized with the ring die, and came out of the chamber but it was a struggle. Here is a pic of that brass.

I am having this same issue with a new BRA barrel. Old barrel worked fine, new barrel has clickers and is much harder to extract. Small base sizing marginally helped. Going to try a small batch of virgin and see if I run into these issues after a couple firings on the new barrel. If I do, it’s rechamber time.

If your fired and resized brass both measure .468” then your chamber is too tight or your sizing die is too loose to work with that brass. Get new brass and you might get away with it but what you got won’t work.

Here are a couple if pics after coloring with a sharpie and firing. The line about a 1/3 up the case measures .466 my other brass that wasn't ran through a ring die measures the same in that spot. Any input is greatly appreciated.

Your fired brass is coming out the same size as your resized brass. Aka, it’s not getting sized enough. That’s what all of your measurements are telling you as well as the other people in here.

You either need to get a new die or a new chamber from what you’re saying. If different brass from multiple places all don’t fit in this new chamber then I’m guessing it’s this new chamber. Or maybe new brass without the other barrels larger chamber engrained in it will be enough... but maybe not for the die you are using with it.

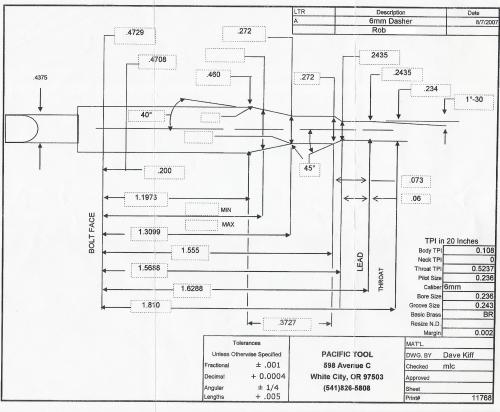

Here is the first google result reamer print

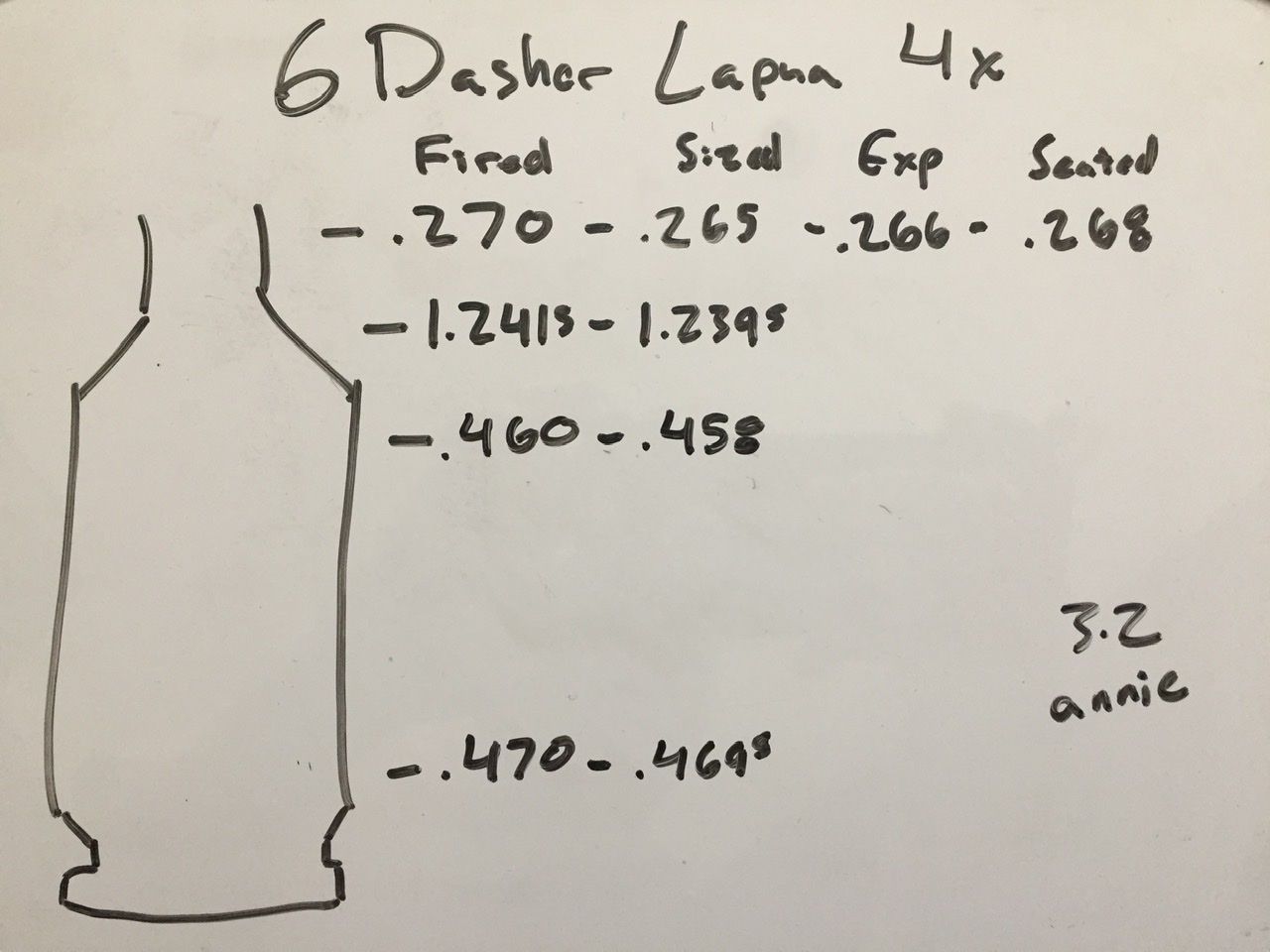

Here is my dasher fired/sized specs

In both cases the base of the chamber and fired brass is .470 something... not .468

You either need to get a new die or a new chamber from what you’re saying. If different brass from multiple places all don’t fit in this new chamber then I’m guessing it’s this new chamber. Or maybe new brass without the other barrels larger chamber engrained in it will be enough... but maybe not for the die you are using with it.

Here is the first google result reamer print

Here is my dasher fired/sized specs

In both cases the base of the chamber and fired brass is .470 something... not .468

Last edited:

Thanks guys. I'm getting new brass headed this way.

I took some one time fired brass and did the sharpie treatment. Its from a different lot and hasn't had the ring die treatment or anything. Same issue.

I took some one time fired brass and did the sharpie treatment. Its from a different lot and hasn't had the ring die treatment or anything. Same issue.

Your fired brass is coming out the same size as your resized brass. Aka, it’s not getting sized enough. That’s what all of your measurements are telling you as well as the other people in here.

You either need to get a new die or a new chamber from what you’re saying. If different brass from multiple places all don’t fit in this new chamber then I’m guessing it’s this new chamber. Or maybe new brass without the other barrels larger chamber engrained in it will be enough... but maybe not for the die you are using with it.

Thanks for the video, very informative!

One other piece of info for context, I’ve gone with chambers that are sized .4715 at the base so that sizing dies match up and provide adequate sizing. I had a chamber that was .4708 at the base and it was small, had a hard time finding dies. If your chamber is actually .468 it’s wicked small and you’ll have a heck of a time. I might call Harrels and ask them for their smallest D5 Dasher die and see if that will work. Even if you run virgin brass you’re eventually going to run into issues with a chamber that small.

One other piece of info for context, I’ve gone with chambers that are sized .4715 at the base so that sizing dies match up and provide adequate sizing. I had a chamber that was .4708 at the base and it was small, had a hard time finding dies. If your chamber is actually .468 it’s wicked small and you’ll have a heck of a time. I might call Harrels and ask them for their smallest D5 Dasher die and see if that will work. Even if you run virgin brass you’re eventually going to run into issues with a chamber that small.

Thats what I afraid of. Over on accurate shooter the general consensus is that I need new brass and im fine with that. BUT if this chamber is as tight as it appears I feel like I may just be kicking the can down the road with new brass. I will check on the die you suggested, I have been searching a lot and saw the D4 recommended for a similar issue for someone else.

Still waiting on new Lapua 6br brass to show up but I did find a piece of BR brass to mess with. I false shouldered it and have fired it 5 times resizing it with my new Harrels die without much issue. After I get the new stuff I'm going to get it going and see what it'll do. I'll definitely follow up here.

On a side note I'm a little confused about measuring the shoulder. Using the bump gauge that was included with my Whidden dies I can measure and bump the shoulder from 1.244 to 1.242. If i take the included Harrels measuring bushing it goes from 1.666 to 1.653. This is me measuring a single piece of brass with both gauges using the same calipers, sizing it and measuring again. If I set the die to only bump .002 using only the Harrels gauge the brass has a little resistance when closing the bolt. Is there a different measurement i should be looking for when using the Harrels?

Sorry for the long post! And thanks in advance!

On a side note I'm a little confused about measuring the shoulder. Using the bump gauge that was included with my Whidden dies I can measure and bump the shoulder from 1.244 to 1.242. If i take the included Harrels measuring bushing it goes from 1.666 to 1.653. This is me measuring a single piece of brass with both gauges using the same calipers, sizing it and measuring again. If I set the die to only bump .002 using only the Harrels gauge the brass has a little resistance when closing the bolt. Is there a different measurement i should be looking for when using the Harrels?

Sorry for the long post! And thanks in advance!

Similar threads

- Replies

- 26

- Views

- 751

- Replies

- 11

- Views

- 1K

- Replies

- 2

- Views

- 109

- Replies

- 0

- Views

- 129

- Replies

- 2

- Views

- 230