All,

I've just built 6mm ARC upper with 18" Shaw barrel and Sons of Liberty Gun Works SOLGW 6.5 Grendel/6mm ARC Bolt Carrier Group and an adjustable gas block. I adjusted gas down to get reliable ejection and empty mag lockup, ejection is going at around 4 o'clock. The rifle shoots sub-MOA 5 round groups on 100 yards with Hornady Black 105gn and just over 1MOA with Hornady Match 108gn. This is all good.

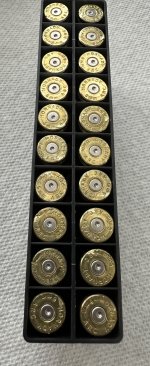

Now what concerns me is that I get ejector marks on most of the casings (see pics), there is lot of brass residue on the bolt face, and the throat on about half of the brass that has throat flat on one side. I understand that sharp edges on the bolt extractor and ejector could be causing marks on the brass and brass residue on the bolt. What could be causing flat throat on the brass?

Also, velocity is about 2520fps for Hornady Black 105gn and about 2480fps for Hornady Match 108gn, I have only about 80 rounds through this barrel so it may speed up little but. I was expecting little bit more velocity from 18" barrel.

Thank you for your help!

Dan

I've just built 6mm ARC upper with 18" Shaw barrel and Sons of Liberty Gun Works SOLGW 6.5 Grendel/6mm ARC Bolt Carrier Group and an adjustable gas block. I adjusted gas down to get reliable ejection and empty mag lockup, ejection is going at around 4 o'clock. The rifle shoots sub-MOA 5 round groups on 100 yards with Hornady Black 105gn and just over 1MOA with Hornady Match 108gn. This is all good.

Now what concerns me is that I get ejector marks on most of the casings (see pics), there is lot of brass residue on the bolt face, and the throat on about half of the brass that has throat flat on one side. I understand that sharp edges on the bolt extractor and ejector could be causing marks on the brass and brass residue on the bolt. What could be causing flat throat on the brass?

Also, velocity is about 2520fps for Hornady Black 105gn and about 2480fps for Hornady Match 108gn, I have only about 80 rounds through this barrel so it may speed up little but. I was expecting little bit more velocity from 18" barrel.

Thank you for your help!

Dan