Thanks. This excites me. Built a few 300prc, may have to get a 7prc and have an experiment to get some data. Would be nice with 180gr Berger @ 300 zillion fps.7lrm has quite a bit more taper and a longer neck. The 7lrm has 87gr powder capacity, whereas the 7-300prc is closer to 94. The prc will still have a 300" long neck.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7-300 PRC Initial Results - Winner

- Thread starter flounderv2

- Start date

Both use the 375 Ruger as parent case I think, it's why I asked.Well I thought it was the 375 ruger? Would be more capacity in the 7-300prc.

7LRM looks to be it's own creation from Gunwerks.Both use the 375 Ruger as parent case I think, it's why I asked.

If I can bump a couple of month old thread, what’s the consensus? Been reading all I can about the 28 Sherman, the 7/300prc, the 7lrm with adg brass, and 28 nos with 400mod bb barrel ideas.. I’m brand new to reloading so I can’t take in 100% of the convo but unless hornady makes the 7prc. This might be the route I go down one day since it seems easier than some others! Almost forget the 7 blaser mag! How do some of you guys feel this 7/300(7prc) stacks up now that you have time under your belt?

Last edited:

I'm with youIf I can bump a couple of month old thread, what’s the consensus? Been reading all I can about the 28 Sherman, the 7/300prc, the 7lrm with ash brass, and 28 nos with 400mod bb barrel ideas.. I’m brand new to reloading so I can’t take in 100% of the convo but unless hornady makes the 7prc. This might be the route I go down one day since it seems easier than some others! Almost forget the 7 blaser mag! How do some of you guys feel this 7/300(7prc) stacks up now that you have time under your belt?

I'd love to hear some feedback on this round in 20-22" barrels

Well the point of having available brass and a small case change makes it winner for 7mm-300 PRC. I already have a wildcat better than what's listed, but I don't like the pain of getting brass and fl sizing.

It's an easy do and if criterian or Shilen can be motivated to make prefit barrels. I run 1:8 twist which is no good for the eldm 180gr. My plan of using 197gr SMKs is also not going well (they need jump or get random spikes in pressure).

Once I start playing with it again AND Berger bullets come available, I work the rifle again.

It's an easy do and if criterian or Shilen can be motivated to make prefit barrels. I run 1:8 twist which is no good for the eldm 180gr. My plan of using 197gr SMKs is also not going well (they need jump or get random spikes in pressure).

Once I start playing with it again AND Berger bullets come available, I work the rifle again.

I just had a customer bring me a 7-300prc reamer and a barrel to fit up.

Will be interesting to see how it goes, I'm super keen to do a spare barrel for myself, but don't have dies to use with it (no bushing 300prc dies currently).

Will be interesting to see how it goes, I'm super keen to do a spare barrel for myself, but don't have dies to use with it (no bushing 300prc dies currently).

Might as well. I’ve been known to have spare engines and transmission that are ready to run, but no project car for them to go in.. yet!I just had a customer bring me a 7-300prc reamer and a barrel to fit up.

Will be interesting to see how it goes, I'm super keen to do a spare barrel for myself, but don't have dies to use with it (no bushing 300prc dies currently).

I used my 7wsm fl bushing die to size a couple 300 prc cases down with a 315 bushing.I have lapua 300 PRC brass, which bushing size do I need to step down to 7mm?

It was just for fun to see how it'd turn out, and it actually worked really well.

One thing I'll say about sizing down with bushings is that the entire neck won't get sized uniformly, you'll end up with a greater neck diameter of approx .005 or more near the shoulder junction.

Also reducing neck diameter more than .006 at a time will cause issues with runout

personally I'd get a cheap FL 7 saum die and use that for your initial sizing.

I'd neck turn after sizing down to take the donut off.

After you've loaded a few rounds measure the neck diameter and subtract .002 for the correct bushing size.

One thing I'd also do is measure the diameter of a fired case and make sure you're getting .004-.006 neck expansion.

If its too tight turn more off the necks

Here's a case I sized down with the 7 wsm die

Shit I saw your post after writing mine...I'd do it in two steps to prevent a bunch of runout. When I did mine I used a 322 bushing, then ran it into a 7 saum neck sizing die to get it sized down all the way to the shoulder then ran a 282 mandrel to neck it back up for seating. This worked well as there was 2-4k runout after all said and done. Bushings will not size it all the way to base of neck/shoulder junction. And this may prevent chambering depending on how tight the headspace is to normal 300prc dimensions.

Good advice

What’s a good neck turning equipment without going to crazy with the priceI used my 7wsm fl bushing die to size a couple 300 prc cases down with a 315 bushing.

It was just for fun to see how it'd turn out, and it actually worked really well.

One thing I'll say about sizing down with bushings is that the entire neck won't get sized uniformly, you'll end up with a greater neck diameter of approx .005 or more near the shoulder junction.

Also reducing neck diameter more than .006 at a time will cause issues with runout

personally I'd get a cheap FL 7 saum die and use that for your initial sizing.

I'd neck turn after sizing down to take the donut off.

After you've loaded a few rounds measure the neck diameter and subtract .002 for the correct bushing size.

One thing I'd also do is measure the diameter of a fired case and make sure you're getting .004-.006 neck expansion.

If its too tight turn more off the necks

Here's a case I sized down with the 7 wsm die

View attachment 7655453

I use a k&m turner with a power adapter to use with a drill, pretty cheap and easy to use.What’s a good neck turning equipment without going to crazy with the price

You'll want a 7mm pilot mandrel for the turner, and a lee auto-prime magnum shell holder.

Before you neck turn you'll need to run each case through a .284 expander mandrel, then set your cutting depth and get to turning.

Make sure to lube the pilot or case necks with imperial sizing wax

I use 21st century mandrels and die cuz they're available in .001 increments for neck expanding, after sizing down with whichever bushing you end up using you can select an expander that's .001-.002 under bullet diameter.

https://21stcenturyinnovation.com/

https://www.precisionreloading.com/cart.php#!c=188

After initial neck sizing(7saum), which full length sizer would be good for follow up reloads?I used my 7wsm fl bushing die to size a couple 300 prc cases down with a 315 bushing.

It was just for fun to see how it'd turn out, and it actually worked really well.

One thing I'll say about sizing down with bushings is that the entire neck won't get sized uniformly, you'll end up with a greater neck diameter of approx .005 or more near the shoulder junction.

Also reducing neck diameter more than .006 at a time will cause issues with runout

personally I'd get a cheap FL 7 saum die and use that for your initial sizing.

I'd neck turn after sizing down to take the donut off.

After you've loaded a few rounds measure the neck diameter and subtract .002 for the correct bushing size.

One thing I'd also do is measure the diameter of a fired case and make sure you're getting .004-.006 neck expansion.

If its too tight turn more off the necks

Here's a case I sized down with the 7 wsm die

View attachment 7655453

I'd use a 300 prc fl bushing die with the appropriate bushing that's. 002 less than your loaded neck diameterAfter initial neck sizing(7saum), which full length sizer would be good for follow up reloads?

I’m going to have Forster hone one of their FL 7 saum sizers, what neck diameter should I specify to neck Lapua 300 prc brass.I'd use a 300 prc fl bushing die with the appropriate bushing that's. 002 less than your loaded neck diameter

This is for initial sizing

Hmm thats kind of a tough one since the brass will become thicker after sizing down.I’m going to have Forster hone one of their FL 7 saum sizers, what neck diameter should I specify to neck Lapua 300 prc brass.

This is for initial sizing

I'd think .315 would be a safe bet, that's what my necked down Hornady case measures with a bullet seated.

What you could do is neck a case down then run a .284 expander through it and see what you get for a diameter

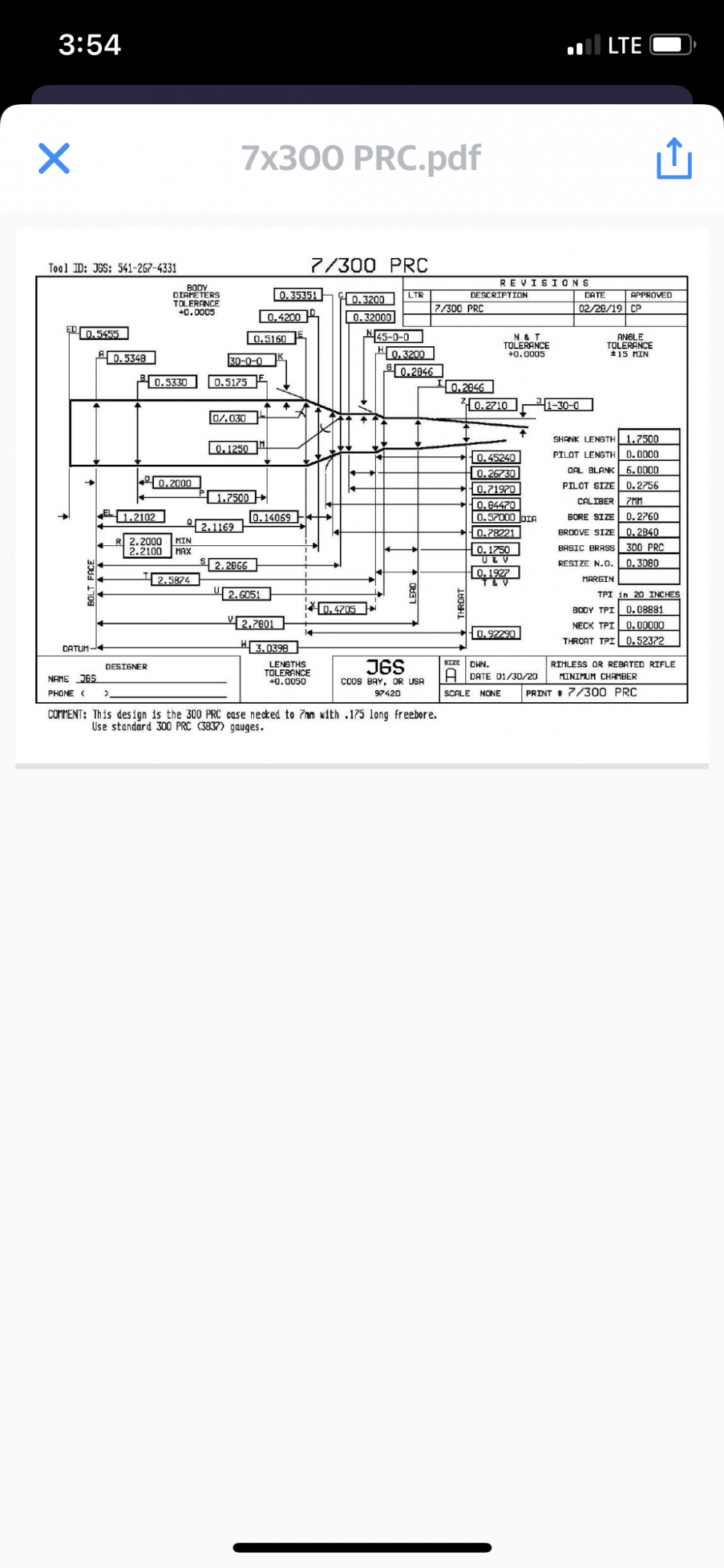

Here is a generic version JGS came up with for my reamer print. I have never made a custom reamer which is why I am posting here. Could you gents critic this reamer version and give me suggestions.

gun info:

Single shot and I will be using the 184 + eight 7mm bullets. 8 twist.

reamer wish list:

1.I would like the bullet to seat appropriately in the neck to avoid donut and still chase lands as needed. it’s fine if it’s a long coal.

2.the body dimensions to remain as parent 300 prc

3. I don’t want a tight neck, something appropriate, I have lapua 300 prc brass to use for this project. While using some calipers I am getting .015 neck thickness reading. I know it’s not the most scientific way but it’s all I have.

gun info:

Single shot and I will be using the 184 + eight 7mm bullets. 8 twist.

reamer wish list:

1.I would like the bullet to seat appropriately in the neck to avoid donut and still chase lands as needed. it’s fine if it’s a long coal.

2.the body dimensions to remain as parent 300 prc

3. I don’t want a tight neck, something appropriate, I have lapua 300 prc brass to use for this project. While using some calipers I am getting .015 neck thickness reading. I know it’s not the most scientific way but it’s all I have.

D

Deleted member 110994

Guest

What are you seeing for velocity with the 195? And what length barrel are you running?My freebore is 240k for 190/195s.

D

Deleted member 110994

Guest

With this setup, is the bullet seated at the neck/shoulder junction? And how much jump/jam is that?My freebore is 240k for 190/195s.

D

Deleted member 110994

Guest

Where did you get your reamer?My freebore is 240k for 190/195s

Hello Gentleman,

I have reached out to PTG and JGS. Both have quoted long lead times on a reamer. Anyone willing to sell, rent or loan their reamer? I’ve got my barrel on the way and don’t really care to wait 3 months.

Thanks in advance.

I have reached out to PTG and JGS. Both have quoted long lead times on a reamer. Anyone willing to sell, rent or loan their reamer? I’ve got my barrel on the way and don’t really care to wait 3 months.

Thanks in advance.

What freebore is your reamer?I'll be doing most updates on my FB page so feel free to follow there but I've also copied all the initial data below.

Some of you may know that I had a reamer made to neck down the new 300PRC to 7mm to see what it would do. I.e. A 7-300prc . I got it back from Alamo Precision Rifles on Friday and was able to put about 30 rounds on it so far and the results are impressive. The case shape and length provides some added benefits over the 28 nosler imo. Speed wise it seems to me that it can easily match or beat the 28 nosler with less effort and lower pressure loads. The 28 nosler advertises it can run a 175 around 3125 and but I'm hearing guys say 195s at 3140-3150 with faster powders and in sure this is a warm if not hot load. I'm curently pushing 184 bergers at 3175 with a slow powder and zero pressure and the Barrel isnt even broken in yet. At these speeds it should already run a 195 at 3140-3150 and also no pressure.I played with it a bit over the weekend using retumbo and 8133 and with 82gn 8133 which is a slightly compressed load, Im at 3173 avg with an SD of 4.5 with 184 hybrid. Barrel is a 28" Hawk Hill CustomNo pressure even with water test. For those that dont know, the water test is pouring water on the case to simulate shooting in rain and if you have a hot load you'll blow primers and get a locked up or hard to open bolt in a heartbeat. I had zero issues and it opened like a normal round. Retumbo is a bit faster still no pressure. This thing is stupid light recoil for the speeds. My original goal with this was to push a 180 pill at a mild 3100-3150 with a powder that gave me almost full case fill and no pressure and it seems to be working spot on for that. Ill post more as I keep testing. brass life test with the same load made it to 7 firings before I had indications of loose primer and thinning case web. I think with something like RL26 or H1000 you could probably push a 180 in the high 3200s to mid 3300s or a 195 around 3200 without being too hot of a load.

Update 1 - 7x firings with 81.4 of 8133 was averaging 3155 with the 184. Everything felt good until the last resize and primer went in pretty easy. Checked the case and saw the faint line of death around the base. Checked the inside and you can feel it getting thin. I wouldnt push it past 5 to be safe depending on your load.

Also realized the Hornady 300 PRC sizing dies are no good. They dont size far enough to the base at all even if you push a piece back to factory dimensions. Hornady you better check your PRC dies or you're going to have a lot of people pissed off they have a sticky bolt on any reloads because your dies arent sizing enough. They arent even changing the dimensions of the case anywhete close to the base from a fired piece to resized . I thought they were sizing way to easy for such a large case and now we know why. They need fixed ASAP.

Update 2 - Between the seating die being a bad design imo which also doesnt work with a Forester Co-AX without chopping down the seating stem, the fact that the sizer doesnt size properly or that the hole diameter for the bushing is massively oversized and causes crazy amounts of neck runout unless you teflon tape the bushing, I'm done with the Hornady "Match Grade" dies. Unfortunately they were the only ones making PRC dies when I needed to get them. I'll probably give them away at some point or maybe do something really silly with them out of frustration. I spoke to Dan Warner today at Warner Tool Company and I'm going to have him make me a set of custom dies. If you havent seen their custom dies, they truly are a work of art with no comparison. I've been considering a set of his dies for a while now and finally going to pull the trigger.

With the 195s will they fit in a CIP magazine?

Trying to get some information on the 7/300PRC:

I have a Savage action that I built into a 300PRC a couple of years ago. Has a Proof pre-fit and it shoots well. When I originally built it, I had plans to use it for hunting but it's fairly heavy and I changed plans and built one on an Origin action with a lighter 10tw barrel. Anyway, I'd like to rebarrel this with a PVA 7/300PRC 28" barrel and use it for ELR. I saw that Redding makes a Neck bushing die for 300PRC and I've already sent PVA a question about their reamer in relation to not having to case neck turn after sizing down. I am not well versed in 7mm and I'm curious if anyone has any thoughts on bushing size for the neck die vs reamer dimensions for the cartridge?

EDITED: I have new Lapua Brass

Looking to reload the 195EOL's.

Appreciate it.

I have a Savage action that I built into a 300PRC a couple of years ago. Has a Proof pre-fit and it shoots well. When I originally built it, I had plans to use it for hunting but it's fairly heavy and I changed plans and built one on an Origin action with a lighter 10tw barrel. Anyway, I'd like to rebarrel this with a PVA 7/300PRC 28" barrel and use it for ELR. I saw that Redding makes a Neck bushing die for 300PRC and I've already sent PVA a question about their reamer in relation to not having to case neck turn after sizing down. I am not well versed in 7mm and I'm curious if anyone has any thoughts on bushing size for the neck die vs reamer dimensions for the cartridge?

EDITED: I have new Lapua Brass

Looking to reload the 195EOL's.

Appreciate it.

If you still have questions please feel free to message me. I have one that I'm using Redding bushing dies with and both Redding and SAC bushings. I have been doing a fair amount of load development and keeping chronograph and strain gauge data logging on everything. Happy to help if I can.Trying to get some information on the 7/300PRC:

I have a Savage action that I built into a 300PRC a couple of years ago. Has a Proof pre-fit and it shoots well. When I originally built it, I had plans to use it for hunting but it's fairly heavy and I changed plans and built one on an Origin action with a lighter 10tw barrel. Anyway, I'd like to rebarrel this with a PVA 7/300PRC 28" barrel and use it for ELR. I saw that Redding makes a Neck bushing die for 300PRC and I've already sent PVA a question about their reamer in relation to not having to case neck turn after sizing down. I am not well versed in 7mm and I'm curious if anyone has any thoughts on bushing size for the neck die vs reamer dimensions for the cartridge?

EDITED: I have new Lapua Brass

Looking to reload the 195EOL's.

Appreciate it.

What bullets are you using? any info on barrel length, velocity, round count, throat erosion (if you've established some way to measure that) would be good to hear about.If you still have questions please feel free to message me. I have one that I'm using Redding bushing dies with and both Redding and SAC bushings. I have been doing a fair amount of load development and keeping chronograph and strain gauge data logging on everything. Happy to help if I can.

I'm running Berger 190 grain Long Range Hybrid Targets.

Krieger 30" Marksman contour (1.20-.90) 8.750 twist with MB&M 4 port brake.

Through all the load development I'm averaging around 3170-3190 fps and I'm currently around 400 rounds or so. I just had an order of more powder and bullets arrive today. I havent been monitoring the throat erosion to be honest, but I guess I could try and check and see what I come up with. So far Ive tried H1000, Win Sta-ball HD, N570, and my new shipment is N565. Happy to keep updating if people are interested.

Krieger 30" Marksman contour (1.20-.90) 8.750 twist with MB&M 4 port brake.

Through all the load development I'm averaging around 3170-3190 fps and I'm currently around 400 rounds or so. I just had an order of more powder and bullets arrive today. I havent been monitoring the throat erosion to be honest, but I guess I could try and check and see what I come up with. So far Ive tried H1000, Win Sta-ball HD, N570, and my new shipment is N565. Happy to keep updating if people are interested.

Have you run any burn analysis say in Gordon’s Reloading tool or Quickloads?I'm running Berger 190 grain Long Range Hybrid Targets.

Krieger 30" Marksman contour (1.20-.90) 8.750 twist with MB&M 4 port brake.

Through all the load development I'm averaging around 3170-3190 fps and I'm currently around 400 rounds or so. I just had an order of more powder and bullets arrive today. I havent been monitoring the throat erosion to be honest, but I guess I could try and check and see what I come up with. So far Ive tried H1000, Win Sta-ball HD, N570, and my new shipment is N565. Happy to keep updating if people are interested.

Yes. I'm using Gordon's along with a Magneto speed, and, a Pressure Trace strain gauge. I'm having a little difficulty modifying the the curve on Gordon's, but the strain gauge results are matching up to the profile curves for the most part.Have you run any burn analysis say in Gordon’s Reloading tool or Quickloads?

Good stuff manI'm running Berger 190 grain Long Range Hybrid Targets.

Krieger 30" Marksman contour (1.20-.90) 8.750 twist with MB&M 4 port brake.

Through all the load development I'm averaging around 3170-3190 fps and I'm currently around 400 rounds or so. I just had an order of more powder and bullets arrive today. I havent been monitoring the throat erosion to be honest, but I guess I could try and check and see what I come up with. So far Ive tried H1000, Win Sta-ball HD, N570, and my new shipment is N565. Happy to keep updating if people are interested.

Keep the updates coming

8-16 update

Yesterday morning I ran a charge weight test with my new shipment of N565 which I have been wanting to try for a while now. I loaded half grain variations from 71-75.5 still running 190 LRHT Berger and magnum primers, all bullets seated the same at 20 thou off. I found really good results with this powder and shot my best groups on average overall compared to all the other powders I've tried. I have found what I would consider the low node for my gun. It's definitely at these charges a slower velocity than what I was seeing with the N570, but the consistency and accuracy over all of the other powders was very spot on. At 75.5 I could definitely feel the pressure starting to come on, but I didn't run into any pressure indicators that would prevent me from creeping up further looking for a higher node. But with what I was seeing it almost didn't seem worth it. The loads stayed very stable almost all the way from 71-73.5 grains along with the accuracy, and even in the upper charges they still shot very well in my opinion.

This is all charge weights shot at the same target. There are 9 shots here and I'm missing the 72 grain shot

Next is the 71 grain load. (Left)

SD 7.6 ES 18

pressure SD 449 psi

avg velocity 3000fps

71.5 grain load

SD 1.4 ES 2

pressure SD 165.9 psi

avg velocity 3008fps

72 grain

SD 4.2 ES 6

pressure SD 165.9 psi

avg velocity 3014 fps

72.5 grain

SD 9.3 ES 22

pressure SD 322 psi

avg velocity 3040

73 grain

SD 10.1 ES 21

pressure SD 39.1 psi

avg velocity 3062 fps

73.5 grain

SD 7.1 ES 14

pressure SD 488.5 psi

avg velocity 3077.3 fps

I have more data available and the strain gauge information including barrel exit times, time under pressure, burn efficiency etc. Planning to go out today again or tomorrow morning and play around with two or three charges and more rounds per charge in the 71.5- 73.5 range and see how things pan out.

Yesterday morning I ran a charge weight test with my new shipment of N565 which I have been wanting to try for a while now. I loaded half grain variations from 71-75.5 still running 190 LRHT Berger and magnum primers, all bullets seated the same at 20 thou off. I found really good results with this powder and shot my best groups on average overall compared to all the other powders I've tried. I have found what I would consider the low node for my gun. It's definitely at these charges a slower velocity than what I was seeing with the N570, but the consistency and accuracy over all of the other powders was very spot on. At 75.5 I could definitely feel the pressure starting to come on, but I didn't run into any pressure indicators that would prevent me from creeping up further looking for a higher node. But with what I was seeing it almost didn't seem worth it. The loads stayed very stable almost all the way from 71-73.5 grains along with the accuracy, and even in the upper charges they still shot very well in my opinion.

This is all charge weights shot at the same target. There are 9 shots here and I'm missing the 72 grain shot

Next is the 71 grain load. (Left)

SD 7.6 ES 18

pressure SD 449 psi

avg velocity 3000fps

71.5 grain load

SD 1.4 ES 2

pressure SD 165.9 psi

avg velocity 3008fps

72 grain

SD 4.2 ES 6

pressure SD 165.9 psi

avg velocity 3014 fps

72.5 grain

SD 9.3 ES 22

pressure SD 322 psi

avg velocity 3040

73 grain

SD 10.1 ES 21

pressure SD 39.1 psi

avg velocity 3062 fps

73.5 grain

SD 7.1 ES 14

pressure SD 488.5 psi

avg velocity 3077.3 fps

I have more data available and the strain gauge information including barrel exit times, time under pressure, burn efficiency etc. Planning to go out today again or tomorrow morning and play around with two or three charges and more rounds per charge in the 71.5- 73.5 range and see how things pan out.

Before I go down this 7-300 PRC rabbit hole what are your guy's COL and bullet type and weight? My press's opening is 3.75" and I want to mock up and see if I can tilt the bullet in, push it up into the die before seating it. Much appreciated

The case is roughly 2.60 and the bullet is 1.60 so it should be a non issue. I have less clearance for my elr ammo to load With the 190lr hybrid seated to have the baring surface/boatail at the neck/shoulder should be in the 3.665-3.7 range depending on where the neck/shoulder moves to when necked down to 7mm.Before I go down this 7-300 PRC rabbit hole what are your guy's COL and bullet type and weight? My press's opening is 3.75" and I want to mock up and see if I can tilt the bullet in, push it up into the die before seating it. Much appreciated.

Also... I think I'm pushing the end of my barrel life on this barrel, so I think I might be close to having some insight into approximate barrel life.

Where are you at with round count?Also... I think I'm pushing the end of my barrel life on this barrel, so I think I might be close to having some insight into approximate barrel life.

ROUGHLY.. Around 1k. Give or take 150. My current throat erosion is about .048k so far from my first measurement that I took around 150ish. Still shooting great, with no spread opening up yet. And there was a fair amount of loads that were way over... Last trip out I was confirming a light node load that ran an SD of 10 over 20 consecutive rounds. And held roughly .6 so I'm trying to see how long I can push it without trying to set the land speed record.

Those are mostly off the top of my head, but I'm happy to check all my notes and confirm.

Those are mostly off the top of my head, but I'm happy to check all my notes and confirm.

Assuming this is a heavy gun, what lenght are you running, do you believe performance is worth the life haircut over running straight 7PRC in a long barrel? I guess it helps being in the US you can actually get the Berger projectiles you want, I'm thinking if I had much more go than the 32 inch 7PRC I have had spun up will likely give me running Hornady projectiles I would have to go to Sierra or something else to avoid blowing them up.

I'm running a 30" Krieger with 8.75 twist. 4 groove and the finish taper at the crown is .90 . I have been running 190 LRHT almost exclusively, minus a box of 184 f-open due to availability. I'm up at altitude (6k) and I'm seeing mostly from 3100 to just under 3300 fps with the 190's. Currently I have a load that I really like with 72.9gr of N565 (ADG brass) running right at 3100 and very reasonable chamber pressure. Ballistic calculator (trued) for where I shoot puts most of my loads supersonic to around 2600-2700.

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 10

- Views

- 606

- Replies

- 25

- Views

- 2K