Re: 7mm-08 "heart transplant"

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Skyking</div><div class="ubbcode-body">Chad love the builds. I have yet to see how any other these shot. Would love to see how some of your guns shoot. Keep us posted. </div></div>

The 7mm-08 is a chooter. We were pressed for time this afternoon as I thought I had Dad duty with picking up the girly from school. I didn't grab the target.

The first 5 were shoot/clean shots. Each cold bore/clean bore shot produced a five shot group that we guessed at around .6" at 100 yards.

Nothing earth shattering but definitely encouraging.

Follow up groups were ok. Around 1/2" inch. For the record I completely suck Suck SUck SUCk SUCK at bench shooting.

I'm betting with the right optics and someone more qualified it'll be a tagger.

Here's a few: (of course no one posts the bad responses. . .

)

Right after moving into the new shop:

http://www.snipershide.com/forum/ubbthre...368#Post2539368

One customer who's very, very satisfied. . .

(hysterical IMHO)

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/GhxqIITtTtU&feature=player_embedded"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/GhxqIITtTtU&feature=player_embedded" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

From this build. . .:

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2287936&#Post2287936

<span style="font-weight: bold">Sent today:</span>

<span style="font-style: italic">Chief,

Hope all is well...

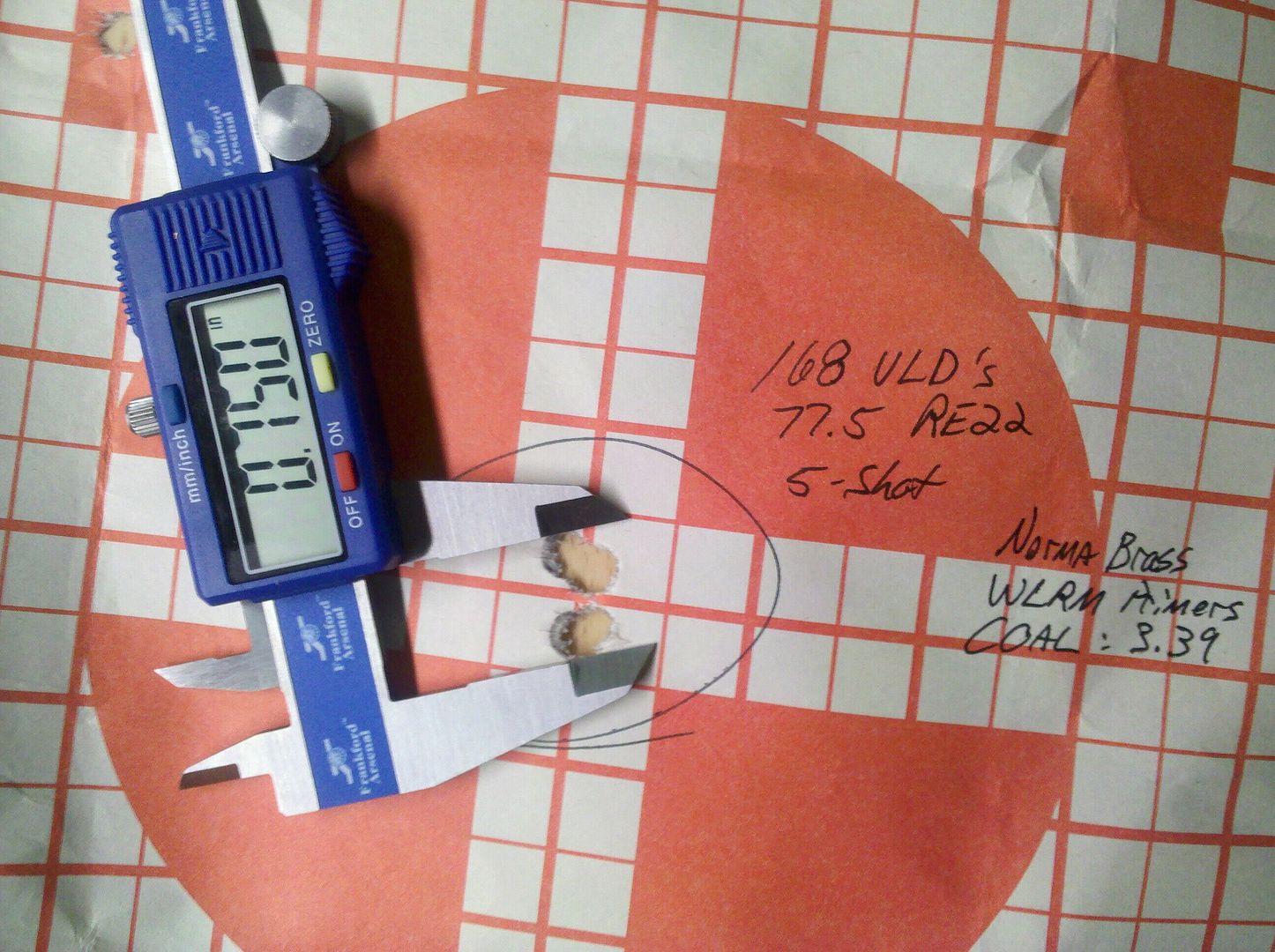

Been whittling down a few different loads and have finally shot a damn good group for me. You're wise beyond your years, my friend. 168 VLD's. .750 at the outside of a 5 shot string. Reloader 22 at 77.5 grains. COAL is 3.39. Berger says they'd like to see 1800 fps to whack a critter which ends this load at 910 yards by my calc at the conditions I shot this tonight. These were shot out the barrel at about round count 40 or so since last cleaning. No pressure concerns on the cases or primer and the avg. vel. was 3357 fps. Berger says the MAX is 77.6 gr. with their 168's.

I jumped up from 76 grains to 77.5 and didn't shoot a 76.5 or a 77.... I know, Boss, .5 grain increment, but I'm inside of 40 days before an Oryx goes down in NM... The 76 grains at the same COAL shot 3229 avg. and wasn't a terrible group, counting the flyer was right at an inch to inch 1/4.

Safe to assume I'll try 78 and see if the group spreads and I'll check the velocity's and the look for pressure problems.

Love this thing... You've hooked me.

My wife hates my new "hobby"... I may miss her... someday...

Jensen</span>

From Email sent 7.21.11:

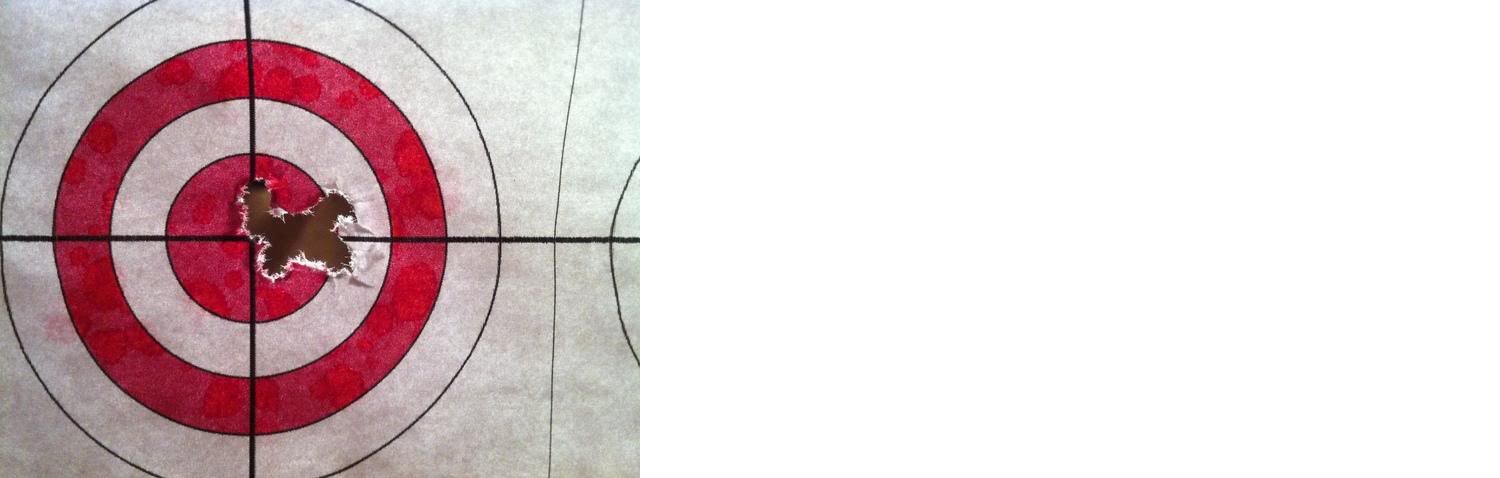

. . . I warmed the barrel up and fouled the bore a little with two 190 SMK's at a rock the size of a car hood at 1034 yards before I shot this group. PDA said 24.75 MOA. First warmup hit right below the rock because I only put in 24.25... Gave it three more clicks up to 25.0 and smoked it right in the middle where I held the crosshairs. I waited about 20 minutes, got set up at 100 yards and shot these five with about 5 minutes between shots.

I've got 77 gr. of RE-22 to try next with the 168's. Still below recommended Max Load by Berger. Absolutely no concerns with the gun, scope, etc.

Lovin' this thing...

Thanks, MAN!

GJ

From This thread:

http://bulletin.accurateshooter.com/2010/11/pride-joy-palma-rifle-in-turkish-walnut/

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2287936&#Post2287936

<span style="font-style: italic">Not much wind. Temps. about 75 in the morning 82 by afternoon. Rain storm blew in and out quick during the last string.

1st. string: 198-14 Fireform loads Berger 105 VLD

2nd. string 198-10 Fireform loads Berger 105 non VLD. Never had much luck with this bullet but had 25 of them laying around so I used them up.

3rd. string 198-10 Match loads Berger 115 VLD. Wind had come up and the light was very bad .

I took 2nd. place overall. Nice to see 2 guy shooting sling and irons in all 3 matches take first and second. Glass in allowed in two of the three matches at this club. I am going to explore the Berger 105 VLD's a bit more. All in all I am very happy with how the gun shot, all 9's were my fault.

John</span>

From Jay C. here on the Hide:

<span style="font-style: italic">

Hi Chad-

Thought you might like to see your chambering job in action as I finally remembered to take a photo to show you. This was a 10-shot string @ 600 yards this morning. I broke one bad shot (a '10' @ 11 o'clock). This is a 600 yard F-Class target (3" X-ring), turned around for visibility with a 3" target dot over the X-ring. You can see the 10 and 9 rings showing through the backside. In scoring parlance, you could call it a 100-8X I guess...

This particular load is holding up very well so far. It's been somewhat difficult zero'ing in on the right load since a 8.5 twist is a bit slow for the 140 Berger VLD and if the velocity drops, it gets pretty wild, but obviously, it still shoots pretty well when your loading practice is sound.

Regards-

Jay Christopherson</span>

Trevor A. Here on the Hide:

Hey Chad, finally got a break in the weather the other day and got out to shoot the .22-250. Seems to shoot everything that I fed it pretty good but settled on a load that grouped fairly small. I included some pics of the 10 shot group at 100 yds that I shot with my final go to load. Thanks again man.

Also I started a thread on SH about the build and the results along with some kind words in regard to you and LRI.

http://snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2590752#Post2590752

Nevermind the hyperventilating phone call from a guy down in LA that Kalli answered. .916" 5 shot center/center spread at 1k yards.

Honest injun!

Nice to have a good day now and again.

Hope this answers your question.

Have a great night.

C.