That’s what I kinda figured I’d have to do soon with Lincoln logs570 in the 338 I’m putting together.You can manually dump charges and let the AutoTrickler finish them off for you. When I load with N570 it clogs the auto throw so this is exactly what I do...manually throw a charge with a Lee scoop and then trickle up. Just disable auto throw in the app.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

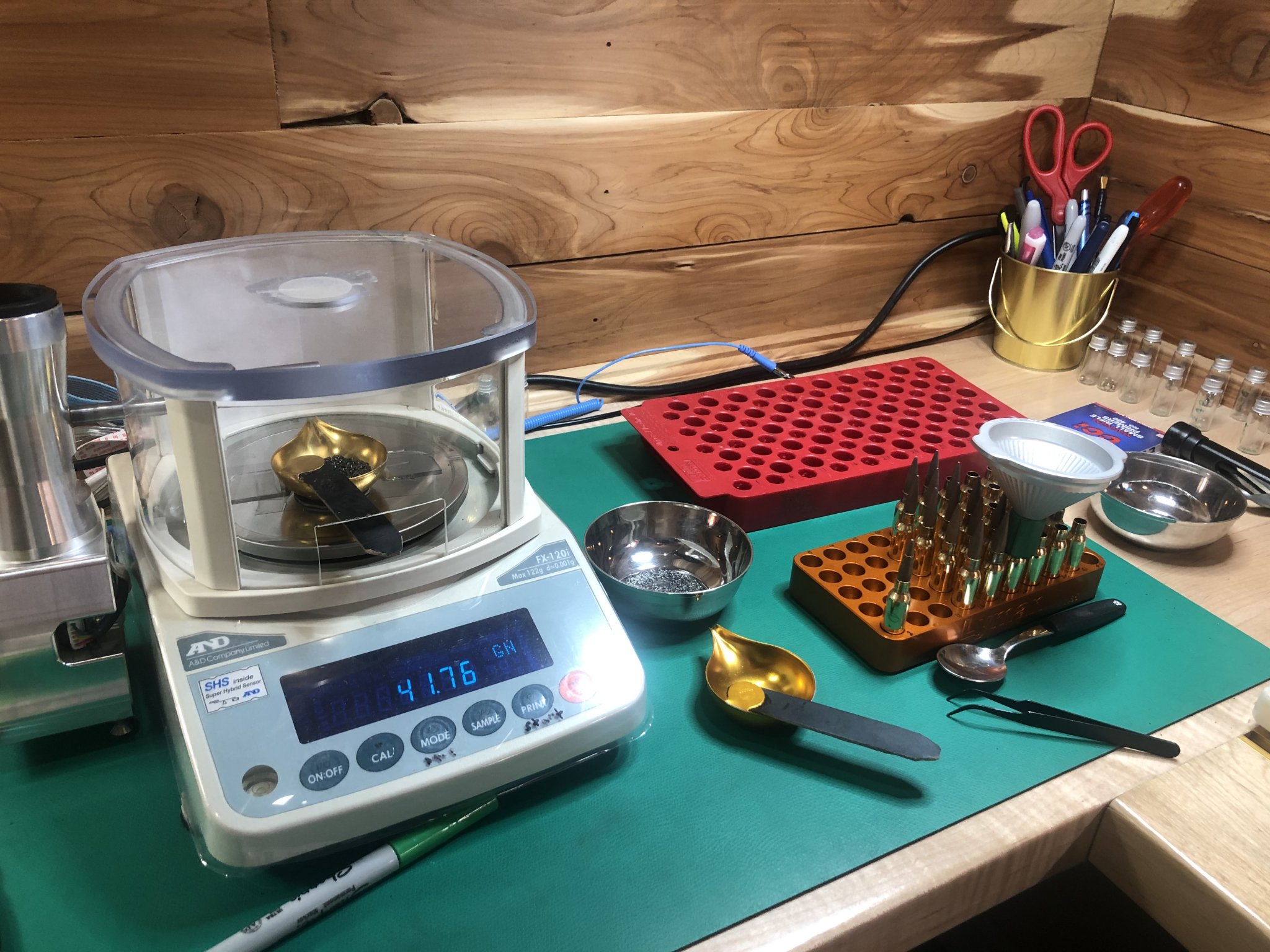

A&D FX-120i

- Thread starter mbeavers1

- Start date

Adam told me some people don’t have a problem with N570 but I’ve never gotten it to work. He said he would try to think of a solution.

FYI - N570 has worked great for me with both 285 ELDM’s and 300 SMK’s.

FYI - N570 has worked great for me with both 285 ELDM’s and 300 SMK’s.

How do you contact adam, I've been emailing him with no luck.Adam told me some people don’t have a problem with N570 but I’ve never gotten it to work. He said he would try to think of a solution.

FYI - N570 has worked great for me with both 285 ELDM’s and 300 SMK’s.

I’ve always just emailed him. He’s been very responsive for both AutoTrickler and Shot Marker questions.

I think the autothrow needs the scale to read 0.02 or less to automatically start — by dropping a pan already close you would need to manually start the autothrow trickler

I do not have the autothrow setup but I did just recieve the fx scale this afternoon — ordered it Tuesday, delivered today (friday) — less than 96 hours from order to delivery — I’m in NJ

I was thinking of just ordering the auto trickler — I already have a 3br powder measure bought back in the 90’s — well made and works great

Thinking out loud here but why not drop the empty pan on the scale, get the trickler running, then drop a short charge out of the 3br into a pan — have a funnel, of the proper length, dropping through the hole in the windscreen of the FX and into the pan thats getting charged by the auto trickler — drop the charge in the pan from the manual measure through the funnel and into the pan on the scale

I just don’t see this method taking much more time and it doesn’t make my redding 3br obsolete

I haven’t tested the limits of when the autothrower triggers but I have set the thrower to high and dump a little powder back in the trickler, place the partial charge back on the scale and it will trickle up to the set weight or if it overthrows by a little instead of dumping all of the powder do the same thing ( dump a grain out or so) and the autothrower doesn’t throw again.

I made a mount for a cheap Lee powder measure so it drops directly into the pan on the scales. It's very quick to throw a few grains under and let it trickle up, I just need to throw it manually once it starts trickling. Saying that, I did just order the autothrow portion as well which will be nice.How many folks are under throwing charges "by hand" (with a manual powder throw) to get close, then tossing the pan into the V3 to auto trickle up to the desired throw?

That seems like it could potentially be as fast as using the full AT V3 set up, no? Or darn close once you have the manual powder thrower dialed in.

Last edited:

Full package deals are usually cheaper.Am I looking at the website wrong or is it more money to buy the trickler and the auto throw separately?

Yep, it's more expensive to buy both separately. I only wanted the trickler to begin with but changed my mind and have ended up paying a bit more for both.Am I looking at the website wrong or is it more money to buy the trickler and the auto throw separately?

Does anyone else see their FX react a little slow or sluggish at times and cause overshooting? I see this from time to time, maybe I don't have something adjusted quite right, as far as fine tuning.. Any suggestions from you fellas that's had your setup for a while? Thanks

Does anyone else see their FX react a little slow or sluggish at times and cause overshooting? I see this from time to time, maybe I don't have something adjusted quite right, as far as fine tuning.. Any suggestions from you fellas that's had your setup for a while? Thanks

No, never. Try recalibrating it? Have calibration weights?

I've seen that, but always attributed it to the autotrickler slowing way down as it got close to target weight. It would keep slowly turning, but not drop any kernels of powder and then eventually drop two or three at once and go over target. I've cured this by using a smaller restrictor nozzle at the end of the autotrickler straw. The nozzle gives a more even powder feed one kernel at a time. I've only gone over target weight twice in the last 200 trickles and only by .02 grains at that.Does anyone else see their FX react a little slow or sluggish at times and cause overshooting? I see this from time to time, maybe I don't have something adjusted quite right, as far as fine tuning.. Any suggestions from you fellas that's had your setup for a while? Thanks

A

A nice shiny picture of what your using would be a nice touch, I really appreciate it. You could PM it to me if you dont want everyone to see your straw.I've seen that, but always attributed it to the autotrickler slowing way down as it got close to target weight. It would keep slowly turning, but not drop any kernels of powder and then eventually drop two or three at once and go over target. I've cured this by using a smaller restrictor nozzle at the end of the autotrickler straw. The nozzle gives a more even powder feed one kernel at a time. I've only gone over target weight twice in the last 200 trickles and only by .02 grains at that.

Oh no... Please don't show us your straw!! We're too bashful!

A

A nice shiny picture of what your using would be a nice touch, I really appreciate it. You could PM it to me if you dont want everyone to see your straw.

Hahahaha..... Some of us are self confident about our straws damn it.... LolOh no... Please don't show us your straw!! We're too bashful!

This is the one I bought, but just because I could get it delivered in one day. There are a ton of them with M6 threads though and just about any of them will work. You'll need to drill it out with a 1/8" drill bit.

Mine after drilling it out. Sorry no straw pics!

Mine after drilling it out. Sorry no straw pics!

Awesome, thank you, so I need the 0.6mm correct?This is the one I bought, but just because I could get it delivered in one day. There are a ton of them with M6 threads though and just about any of them will work. You'll need to drill it out with a 1/8" drill bit.

Mine after drilling it out. Sorry no straw pics!

View attachment 7556685View attachment 7556689

That would work, but any of them would work since that is just the internal nozzle diameter which you will drill out anyway. The important spec is the M6 threads since that is what fits the autotrickler straw.Awesome, thank you, so I need the 0.6mm correct?

Ok, I got ya now... excuse my ignorance...That would work, but any of them would work since that is just the internal nozzle diameter which you will drill out anyway. The important spec is the M6 threads since that is what fits the autotrickler straw.

Does anyone else see their FX react a little slow or sluggish at times and cause overshooting? I see this from time to time, maybe I don't have something adjusted quite right, as far as fine tuning.. Any suggestions from you fellas that's had your setup for a while? Thanks

Old thread i know - i see this mostly when powder is left in the autotrickler overnight and the kernels absorb moisture, and then clump together the next day.

Try turning the trickler one “click” at a time by hand, and you will see clumps coming out once every 10 or 15 “clicks”. Lesson learned! Trick is to clean out the hopper after reloading every time and put it back in the plastic bottle. I also run a large electric dehumidifier in my reloading room, and keep a desiccant inside my ammo storage chest. Humidity stays fairly constant.

In my experience, if you load to within 0.04 gn (two large kernels), you are fine. Yes you can do slightly better but it makes no practical difference to ES or to group size on paper.

Actually, that piece that Hemi suggested above helped alot, keeps it from piling up and a bunch falling out all at one time. I'm sure your point is also valid so thanks...Old thread i know - i see this mostly when powder is left in the autotrickler overnight and the kernels absorb moisture, and then clump together the next day.

Try turning the trickler one “click” at a time by hand, and you will see clumps coming out once every 10 or 15 “clicks”. Lesson learned! Trick is to clean out the hopper after reloading every time and put it back in the plastic bottle. I also run a large electric dehumidifier in my reloading room, and keep a desiccant inside my ammo storage chest. Humidity stays fairly constant.

In my experience, if you load to within 0.04 gn (two large kernels), you are fine. Yes you can do slightly better but it makes no practical difference to ES or to group size on paper.

Actually, that piece that Hemi suggested above helped alot, keeps it from piling up and a bunch falling out all at one time. I'm sure your point is also valid so thanks...

I will also try the mod Hemi suggested. Order placed!

Last edited:

I will also try the mod Hemi suggested. Order placed!

Arrived within 24 hours, and got it installed today. Works well. System is slightly slower but overthrows are far less than before.

@HemiPowrd: Good modification, thanks for posting this!

YeaOld thread i know - i see this mostly when powder is left in the autotrickler overnight and the kernels absorb moisture, and then clump together the next day.

Try turning the trickler one “click” at a time by hand, and you will see clumps coming out once every 10 or 15 “clicks”. Lesson learned! Trick is to clean out the hopper after reloading every time and put it back in the plastic bottle. I also run a large electric dehumidifier in my reloading room, and keep a desiccant inside my ammo storage chest. Humidity stays fairly constant.

In my experience, if you load to within 0.04 gn (two large kernels), you are fine. Yes you can do slightly better but it makes no practical difference to ES or to group size on paper.

I always empty mine out.

I still giggle a bit when I use mine.

It really is a slick system.

Even tossing 90+ grains of N565 and having to trickle 2+ grains it’s still super fast.

I can't take credit for this mod. I've seen Elfster and a few others mention it. I was having trouble finding out where to order one and figured out the thread pitch was the same as the 3D printer nozzles. Tons of those available so it's easy to acquire one.Arrived within 24 hours, and got it installed today. Works well. System is slightly slower but overthrows are far less than before.

@HemiPowrd: Good modification, thanks for posting this!

I found mine was slower after adding the restrictor nozzle, but made two adjustments to get the speed back.

1. Changed the angle of the autotrickler straw so it was slightly lower over the cup (more positive angle). This speeds the feed back up slightly.

2. Moved the lever on the back of the scale all the way to the right (as viewed from the front of scale). This lets the trickler feed powder at the faster rate for a slightly longer period so it gets closer to the final programmed weight before it starts to slow down.

You'll have to play around with the above adjustments as they interact with each other, but once you get it right it works really well.

I've also considered drilling out the orifice to a slightly larger size, but with the above adjustments it wasn't needed. With larger extruded powders it might still help speed things up.

Last edited:

I can't take credit for this mod. I've seen Elfster and a few others mention it. I was having trouble finding out where to order one and figured out the thread pitch was the same as the 3D printer nozzles. Tons of those available so it's easy to acquire one.

I found mine was slower after adding the restrictor nozzle, but made two adjustments to get the speed back.

1. Changed the angle of the autotrickler straw so it was slightly lower over the cup (more positive angle). This speeds the feed back up slightly.

2. Moved the lever on the back of the scale all the way to the right (as viewed from the front of scale). This lets the trickler feed powder at the faster rate for a slightly longer period so it gets closer to the final programmed weight before it starts to slow down.

You'll have to play around with the above adjustments as they interact with each other, but once you get it right it works really well.

I've also considered drilling out the orifice to a slightly larger size, but with the above adjustments it wasn't needed. With larger extruded powders it might still help speed things up.

Good info. Have already done item 2, and it helped a lot to get some/most of the speed back. Will now try item 1 as well, should help too.

Actually ordered two nozzles (in case i messed up the first one!) and then drilled different size holes: 0.125” and 0.178”. Still running the nozzle with the smaller 1/8’th hole. Currently using RL-17, which has variable kernel size, some are quite long (some fused together) compared to say H4350.

Guess the bigger hole diameter becomes option 3.

Last edited:

BTW: Did a “drift test” the past 2 weeks: With a plastic cup being used to zero the setup and then writing down the negative weight nr 3x per day. Max deviation i got was 0.04 gn, and that happened only twice in 2 weeks, usually the error is zero (90% of the time, sometimes for days at a time), while only a few days showed a 0.02 gn max error, which is tiny. Left the scale on all the time.

Also modified a yellow beam scale metal pan by adding a long stem made from cardboard attached with Gorilla glue. This pan had 0.12 gn variations while the plastic pan usually had none! It seems the paper-like cardboard material absorbs water vapor and changes weight, and quite a lot too. Glue was applied 6 months ago, so probably not “off-gassing” anymore. That was a surprise.

Also modified a yellow beam scale metal pan by adding a long stem made from cardboard attached with Gorilla glue. This pan had 0.12 gn variations while the plastic pan usually had none! It seems the paper-like cardboard material absorbs water vapor and changes weight, and quite a lot too. Glue was applied 6 months ago, so probably not “off-gassing” anymore. That was a surprise.

Last edited:

Ha! Have you been in my garage snooping?You are correct that the FX120 is a major upgrade compared to any scale with a 0.1 gn resolution. I have a V1 Autotrickler system, and i love it! Will probably at some point upgrade to the V3.

Even though superb, the FX120 does not always deliver 0.02 accuracy over 100 rounds, as it can occasionally drift. This is fairly rare, but it can happen if ambient conditions change. You have to preheat the scale for at least 15 minutes before use or there will be substantial drift. I just keep it on for days at a time.

Also, you can load very good ammo with 0.04 gn resolution, because other factors like neck tension differences, bullet and primer weight variations and progressive barrel fouling dominate once you load to two kernel accuracy. In my experience, 2 kernel accuracy is the point of diminishing returns.

My FX120 scale runs on a high end power filter/surge suppressor, and is sitting on an anti-static mat which is properly earthed to avoid static buildup, no fluorescent lights anywhere.

A stray kernel can accidentally get onto your scale tray and go unnoticed for a while. You really have to keep an eye on the negative number every time you remove the pan. Train yourself to look at it before you dump the powder into the case. Once or twice in a loading session you will see that “something” has happened.

Have run the experiment where i loaded 50 rounds as best i can, tweezer in hand, then carefully put bullets upside down in each case to prevent spillage, waited a few hours, and then weighed them all a second time, being super careful. ES was 0.06 gn (2-3 kernel accuracy) and SD was 0.016 gn. Good but not perfect. [Btw: This testing method is flawed: Ideally we should use a Sartorius GD503 or equivalent scale that has 0.001 gn resolution. Since i don’t own one me did the best me could.]

Yes - by all means get one, it is superb, just learn how to use it well: It is sensitive to drafts, so turn off the AC and close the door. I cut a small rectangular hole in the bottom of the front screen and made it slightly larger than the pan, and cut a round hole in the side screen for the trickler spout. Note: If you remove one of the screens, your measurement error will double to 0.07 gn or more. If you use it with no screens, accuracy is less than 0.1 gn and you have wasted your money. If you don’t believe me, try it both ways.

Also: It needs to be mounted on a stable flat surface, and no milligram scale likes vibration, like a truck passing in the street, or the user bumping the table. A granite slab helps. Just mark the position of the feet on the mat and mark the position of the mat on the table so you can pick up if anything got bumped or moved, and recalibrate the scale.

My SDs came down from 12 fps to 6-9 fps range when switching from a 0.1 scale to a 0.02 scale. But understand that in reality it is closer to a 0.05 gn scale. And neck tension differences have a bigger impact than 2 kernels of powder. [Buying a scale capable of 0.001 gn (1/10’th of a kernel of powder) is overkill IMHO (unless you plan to split kernels with a carpet knife???), but if budget is no constraint, go for it. If you are in the BR game and weight sort your primers, you will appreciate the extra resolution.]

Good luck!

I started with a CM1500 that I got brand new off CL for cheap, but found that it wasn't dead nuts consistent like I wanted so bought the V1 setup, then upgraded the plate, cup and hopper from Area 419, then finally bought the V3 upgrade which hopefully will allow me to use it with spherical powder, unlike that Lee thrower that spewed powder everywhere. I too have mine on a granite surface plate and a Trip Lite line conditioner

Attachments

Last edited:

I will say that my CM1500 with discharge insert throws Alliant Power Pro Varmint like a boss. +/- .02g is standard, whereas with extruded RL16 or H4350 I have to set it for .1 under weight and trickle the rest in. So it's the FX120 for extruded and the CM1500 for spherical.

Code seems to be expired, fair enough after the significant time frame passsing. Anyone have an update on the most economical way to purchase an FX120i? TIA

Its still CE products, only now they dont have msrp listed price restrictions from the manufacturer anymore so they can post a lower price by default and not require you enter a coupon at checkout to take the money off.Code seems to be expired, fair enough after the significant time frame passsing. Anyone have an update on the most economical way to purchase an FX120i? TIA

That said, shit has gotten more expensive the last two years, the days of sub500 fx120is is over.

I would check data weighing systems. They were quick to get me a quote and was 5-10 cheaper then CE when I bought mine a couple years ago. They are also in the states so shipping was quicker and I'm not patient.Code seems to be expired, fair enough after the significant time frame passsing. Anyone have an update on the most economical way to purchase an FX120i? TIA

I know this is a old thread but I wanted to thank you for sharing the file. Printed it and used it for the 1st time last nice. Very nice!I made a mount for a cheap Lee powder measure so it drops directly into the pan on the scales. It's very quick to throw a few grains under and let it trickle up, I just need to throw it manually once it starts trickling. Saying that, I did just order the autothrow portion as well which will be nice.

View attachment 7556034

Your lid looks different then my stock one. Did you print that as well?

Hope your active and you see this. Thanks again!

Similar threads

- Replies

- 14

- Views

- 1K