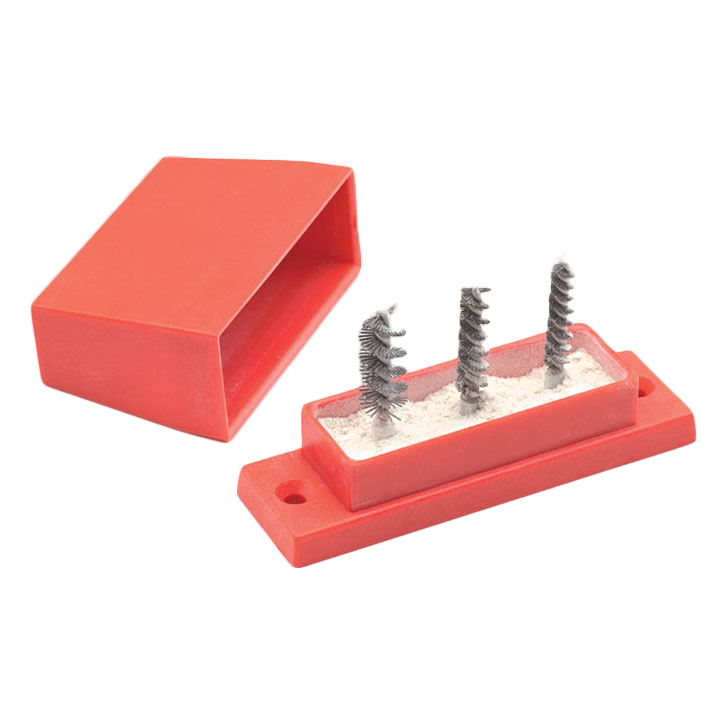

Is there a way to correct galling in the necks of cases due to the use of ss media and tumbling or ultrasonic cleaning? I know that you can lube to help mitigate the galling, but just wondered if there is a way to polish it out.

What is the best practice to prevent the galling in the first place? Tumbling with soapy water?

What is the best practice to prevent the galling in the first place? Tumbling with soapy water?