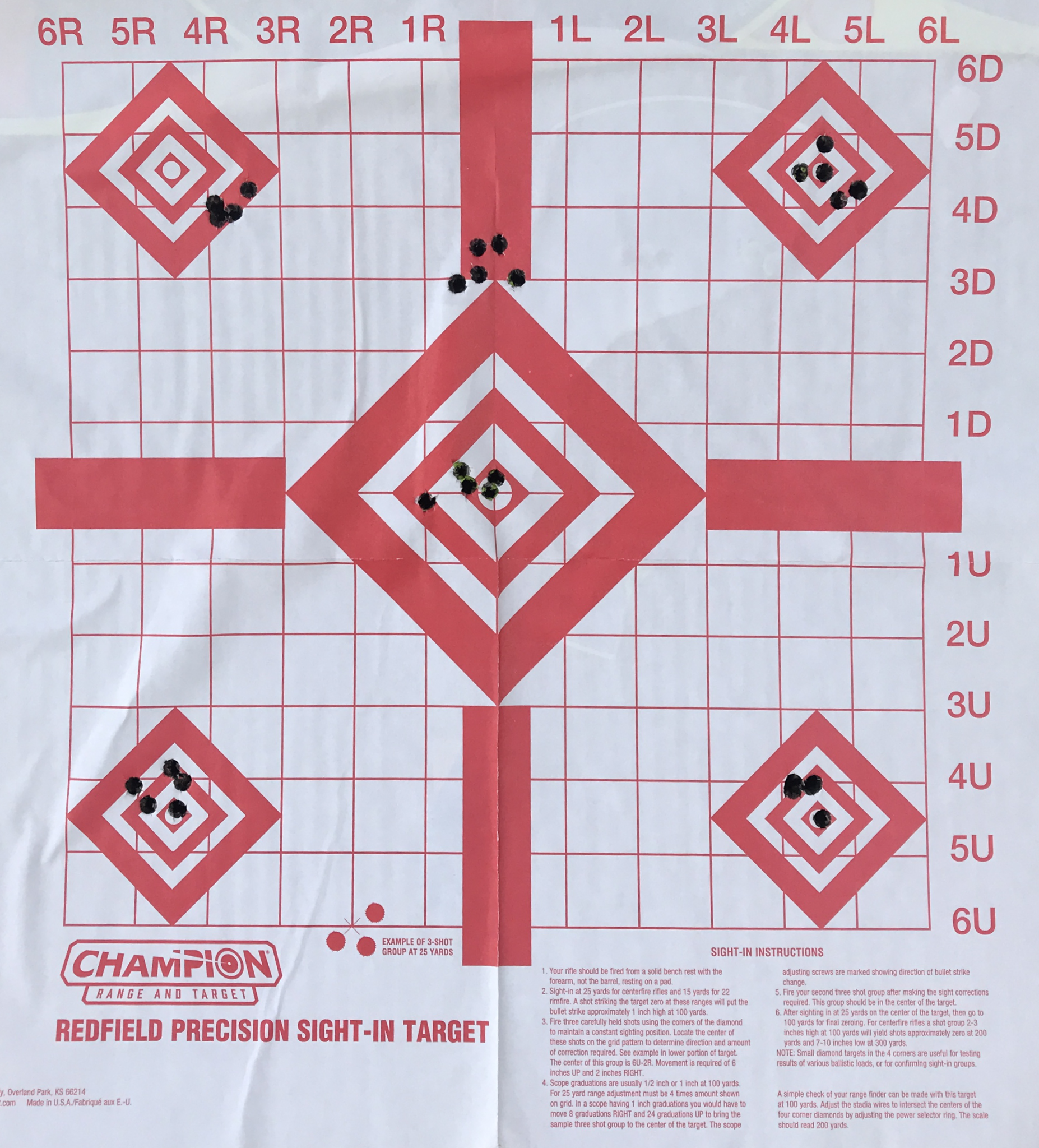

Thats how my 1500 shot ELD bullets. Shot nice clover leafs with FGMM 168. How long are you loading your rounds and what mag are you using? I just got some 155 SMKs to try. I have heard of some Howas not shooting well. I think they have a long throat.I have a HOWA 1500 HS Precision in 308 with a 26" 1:10 twist semi heavy barrel. I have between trying to work up a load that shoots well in the gun but what I'm typically getting is about 1.5" 5-shot groups at 100 yards...See representative groups below. I have tried 168 grain SMK BTHPs and 175 grain SMK BTHPs using IMR 4064 and IMR 3031 but the below is about as far as I've gotten which is far from impressive.

One thing I have noticed is that my HS Precision Stock has rub marks inside the barrel channel. It is actually my 2nd HS Precision stock. The first one straight up contacted the barrel channel and HS Precision sent me a second one for free which at least would pass a piece of paper between the barrel and barrel channel. Another thing I have noticed is that even when following HS Precision's stock installation instructions to the letter and torquing the action screws to 65 inch lbs, I can move the barrel relative to the barrel channel with fairly minimal hand force and putting pressure on the stock reduces the gap between the barrel and barrel channel.

Anyway, I've heard a lot of good things about HOWA 1500s, the action looks very solid, the trigger is great too (for a factory trigger) but what I'm seeing so far is pretty underwhelming. I'm thinking it might be the stock that's the culprit but I'm not looking to drop $100s in a new stock to try to find out if that's the case. I am considering just putting some business cards under the barrel at the end of the stock to create some pressure on the barrel. This is what the Weatherby S2 stock does in the Vanguard series with a similar barrel profile, as I understand it.

Any thoughts would be appreciated. It just sucks that I can't seem to get this one to shoot.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Accuracy Issues with HOWA 1500 HS Precision

- Thread starter mikehill85

- Start date

I’ve needed to skim bed the entire inlet on an HS 700 inlet. The action would rock on the bedding block. I’d definitely start with skim bedding and relieving the barrel channel for a good free float.

I'm loading them about 30 thousandth off the lands. Today I actually had a really good 4-shot group with a 175 grain SMK BTHPs. 0.4" at 100 yards. I'm going to reload a few and try that load again tomorrow and see if it was a fluke or not. How far off the lands are you loading yours? I had thought about going deeper into the case to get extra friction on the bullet (which might lead to more consistent groups). As for the magazine, I am just using the bottom metal that came with the rifle. Loading into the lands isn't an option if you want to use the magazine given how long the throat is.Thats how my 1500 shot ELD bullets. Shot nice clover leafs with FGMM 168. How long are you loading your rounds and what mag are you using? I just got some 155 SMKs to try. I have heard of some Howas not shooting well. I think they have a long throat.

I wouldn't get down in the mouth if the rifle doesn't group 0.4" every time. Being that it's not a purpose built BR rifle, it is perfectly normal for it to shoot groups ranging 2 to 3 times that size, at least.I'm loading them about 30 thousandth off the lands. Today I actually had a really good 4-shot group with a 175 grain SMK BTHPs. 0.4" at 100 yards. I'm going to reload a few and try that load again tomorrow and see if it was a fluke or not. How far off the lands are you loading yours? I had thought about going deeper into the case to get extra friction on the bullet (which might lead to more consistent groups). As for the magazine, I am just using the bottom metal that came with the rifle. Loading into the lands isn't an option if you want to use the magazine given how long the throat is.

Anyhow, if you can get a good zero POI sorted, it's really only the mean radius that matters a damn anyway. It's the mean radius around the POI which tells the real tale.

I couldn't agree more on mean radius. There's a very interesting article called "Statistical Measures of Accuracy for Riflemen and Missile Engineers" that goes into why extreme spread which everyone uses (and why I mention it) is one of the worst possible measures of a rifle's precision. It throws out the data about every shot except for two...Mean Radius has data about the coordinates of every shot built in and is less prone to being ruined by "flyers". Mean radius is a much more efficient measure of a rifle's precision and a much more meaningful metric.I wouldn't get down in the mouth if the rifle doesn't group 0.4" every time. Being that it's not a purpose built BR rifle, it is perfectly normal for it to shoot groups ranging 2 to 3 times that size, at least.

Anyhow, if you can get a good zero POI sorted, it's really only the mean radius that matters a damn anyway. It's the mean radius around the POI which tells the real tale.

Last edited:

There was another issue I had with my rifle that I found not long ago.I couldn't agree more on mean radius. There's a very interesting article called "Statistical Measures of Accuracy for Riflemen and Missile Engineers" that goes into why extreme spread which everyone uses (and why I mention it) is one of the worst possible measures of a rifle's precision. It throws out the data about every shot except for two...Mean Radius has data about the coordinates of every shot built in and is less prone to being ruined by "flyers". Mean radius is a much more efficient measure of a rifle's precision and a much more meaningful metric.

When I bought my scope I purchased a pair of MDT elite scope ring/ bases which, I think are excellent value for the money.

During load development, I'd notice these stringing shots that always seemed to move up & left or up & right. This didn't happen every time I shot but I have quite a few targets with this same shot stringing.

Anyhow, long story short, instead of the usual square pic rail cross pins, they have round double scalloped pins which must be orientated in one direction only. Since I need reading glasses, I didn't see this & have been mounting the scope on the pic rail with the cross pins the wrong way about or worse, one correct & the other upside down. Initially I did notice that the cross pins were round & thought that was unusual because all my other pic rail mounts have square cross pins. Not wearing my glasses though, I couldn't see any detail so just thought they were round & I suppose both pins must have been 180 deg out so both looked the same. I simply assumed the pins were round.

Since mounting the scope properly, no more stringing & the shots seem more evenly dispersed.

Thought it worthwhile mentioning. Might be something else to check while you're going.

I had a similar issue once with my scope ring base screws. The part that holds the rings to the base had an oblong hole and could be mounted in two different ways (with gravity forcing it into the wrong orientation if you weren't careful. My scope was visibly canted to one side and eventually I figured out the problem.There was another issue I had with my rifle that I found not long ago.

When I bought my scope I purchased a pair of MDT elite scope ring/ bases which, I think are excellent value for the money.

During load development, I'd notice these stringing shots that always seemed to move up & left or up & right. This didn't happen every time I shot but I have quite a few targets with this same shot stringing.

Anyhow, long story short, instead of the usual square pic rail cross pins, they have round double scalloped pins which must be orientated in one direction only. Since I need reading glasses, I didn't see this & have been mounting the scope on the pic rail with the cross pins the wrong way about or worse, one correct & the other upside down. Initially I did notice that the cross pins were round & thought that was unusual because all my other pic rail mounts have square cross pins. Not wearing my glasses though, I couldn't see any detail so just thought they were round & I suppose both pins must have been 180 deg out so both looked the same. I simply assumed the pins were round.

Since mounting the scope properly, no more stringing & the shots seem more evenly dispersed.

Thought it worthwhile mentioning. Might be something else to check while you're going.

BTW. I went shooting again today using one of my best loads. Since I'm shooting off a bipod on a concrete surface and have no muzzle brake I was getting some bipod bounce and decided to use some c-clamps to clamp a board across the bench to give me something to lean into. The first group I shot leaning into the board is the below 5-shot group. I couldn't be happier. That's a 0.3" group with a mean radius of 0.124". I think she's a shooter. I may just bed the action, float the barrel, and call it a day.

Last edited:

Yeah. The average of the groups I did using pushing into the board was 0.75" for 5-shot groups, which is still considerably better than HOWA's 1 MOA guarantee for 3-shot groups and about half the size of the groups I was shooting before. The 0.3" group I posted also by far the best group I've shot in my life. Not impressive for most people on here, I'm sure, but I'm pleased with it.Seems very good.

Not every group will be like that though.

Last edited:

I've been utilizing the GRT program with very excellent results. All my load development since using powder charges to align with OBT has been 100% so far.Yeah. The average of the groups I did using pushing into the board was 0.75" for 5-shot groups, which is still considerably better than HOWA's 1 MOA guarantee for 3-shot groups. This is also by far the best group I've shot in my life. Not impressive for most people on here, I'm sure, but I'm pleased with it.

Loads that I'd worked up prior to using OBT which were my best groupers have all agreed with the GRT OBT velocities. The 1st thing I did was to input all data from my good performing loads & run comparisons in the GRT program & I was astounded at how they've all aligned very closely with actual charge weights & velocities.

Thanks for the tip. I downloaded it today. It seems very useful.I've been utilizing the GRT program with very excellent results. All my load development since using powder charges to align with OBT has been 100% so far.

Loads that I'd worked up prior to using OBT which were my best groupers have all agreed with the GRT OBT velocities. The 1st thing I did was to input all data from my good performing loads & run comparisons in the GRT program & I was astounded at how they've all aligned very closely with actual charge weights & velocities.

So far I've found it to be very good, especially when I initially compared the OBT loads to previously tested loads.Thanks for the tip. I downloaded it today. It seems very useful.

You will have to take some H20 volume measurements to input into the column on the left. That's easy enough. I used Blue Tac to block the flash hole & fill the primer pocket & a small syringe bottle to fill the cases.

If you load a new cartridge into the program, it will come up with it's own velocity which can be close at times.

The best way is to use some previous velocity data or load new cartridges with an initial load near max charge, to get some velocity data to input into GRT. This is important because it sets a real world value so GRT can compensate the powder burn characteristics to agree with the measured velocity data.

It can be a bit tricky to know how to use it. If you need a hand give me a shout.

Update: I bedding and opened up the forend to get proper clearance. I thought I'd need to repaint inside the forend. It turns out that the black inside the stock is carbon fiber or something similar and it is black all the way through and I didn't even have to paint it. I just took a large socket and opened up the channel with some sand paper. It really couldn't have been easier.

I most certainly will. Thanks so much for your time and advice.So far I've found it to be very good, especially when I initially compared the OBT loads to previously tested loads.

You will have to take some H20 volume measurements to input into the column on the left. That's easy enough. I used Blue Tac to block the flash hole & fill the primer pocket & a small syringe bottle to fill the cases.

If you load a new cartridge into the program, it will come up with it's own velocity which can be close at times.

The best way is to use some previous velocity data or load new cartridges with an initial load near max charge, to get some velocity data to input into GRT. This is important because it sets a real world value so GRT can compensate the powder burn characteristics to agree with the measured velocity data.

It can be a bit tricky to know how to use it. If you need a hand give me a shout.

Sounds like you've got it under control.Update: I bedding and opened up the forend to get proper clearance. I thought I'd need to repaint inside the forend. It turns out that the black inside the stock is carbon fiber or something similar and it is black all the way through and I didn't even have to paint it. I just took a large socket and opened up the channel with some sand paper. It really couldn't have been easier.

A few things I've done is to coat the rear of the bolt lugs with bearing/Prussian blue or, you can use a texter/ felt tip marker to check the amount & consistency of mating surface of the bolt lugs. Same thing with the recoil lug in the stock. That's the major reason why I bedded the ACC. The recoil lug was touching mainly on the left side & I believe the reason why it would kick so violently to the left. That improved by 90% after bedding.

You may as well check those things while you're going.

Yeah. I have some Prussian blue so I’ll give it a try. I think bedding it should help (I bedded the entire length of the action). I used to be able to pull the barrel from side to side with my fingers even when it was torqued to 65 inch lbs. I can’t seem to do that now. I also don't think the HS Precision stock "pro-center technology" which is just two set screws touching the recoil lugs on the left and right side is a good idea. They don't make much contact with the recoil lug and they probably put uneven stresses on it. The aluminum part of the bedding block is visible so I believe I am getting good contact with back of the recoil lug and the bedding block but I will check with Prussian blue.Sounds like you've got it under control.

A few things I've done is to coat the rear of the bolt lugs with bearing/Prussian blue or, you can use a texter/ felt tip marker to check the amount & consistency of mating surface of the bolt lugs. Same thing with the recoil lug in the stock. That's the major reason why I bedded the ACC. The recoil lug was touching mainly on the left side & I believe the reason why it would kick so violently to the left. That improved by 90% after bedding.

You may as well check those things while you're going.

This was my first time bedding an action and I nearly had a disaster with epoxy getting under my painters tape onto the stock. Luckily I noticed this before it set completely and was able to use some alcohol to clean it up. Whew!

Yes, it's risky stuff. I used JB weld & read some advice on Snipers Hide about a good reliable release agent to ensure it wouldn't stick where it wasn't wanted. The release agent I used was Silicon spray which worked very well however, when it came time to remove the action after bedding, I couldn't move the action at all. My 1st thoughts were "sheeeeyiiit". Turned out the Silicon had done it's job but, because I had completely enclosed the recoil lug, front & rear, as well as the action tang, the action must be worked out of the chassis by keeping it parallel. It fits in there snug as a bug. I can turn the rifle upside down & shake it & it doesn't move a millimetre.Yeah. I have some Prussian blue so I’ll give it a try. I think bedding it should help (I bedded the entire length of the action). I used to be able to pull the barrel from side to side with my fingers even when it was torqued to 65 inch lbs. I can’t seem to do that now. The aluminum part of the bedding block is visible so I believe I am getting good contact with back of the recoil lug and the bedding block but I will check with Prussian blue.

This was my first time bedding an action and I nearly had a disaster with export getting under my painters tape into the stock. Luckily I noticed this before it set completely and was able to use some alcohol to clean it up. Whew!

Since you've bedded the action, it's probably fine but, I spose it wouldn't hurt to check.

Lets hope these mods do the trick.

Fingers crossed. I had the same "Oh sheeeyiiit!" moment with my rifle. It didn't seem to want to come out but pulling it straight up did the trick. All I can say is there's really no way these modifications can hurt. Other than that, I just need to shoot it and find out, which I'll probably try this weekend.Yes, it's risky stuff. I used JB weld & read some advice on Snipers Hide about a good reliable release agent to ensure it wouldn't stick where it wasn't wanted. The release agent I used was Silicon spray which worked very well however, when it came time to remove the action after bedding, I couldn't move the action at all. My 1st thoughts were "sheeeeyiiit". Turned out the Silicon had done it's job but, because I had completely enclosed the recoil lug, front & rear, as well as the action tang, the action must be worked out of the chassis by keeping it parallel. It fits in there snug as a bug. I can turn the rifle upside down & shake it & it doesn't move a millimetre.

Since you've bedded the action, it's probably fine but, I spose it wouldn't hurt to check.

Lets hope these mods do the trick.

Update: For anyone interested, HS Precision responded today to my inquiry about the suitability of the PSS139 for HOWA 1500 rifles with a No. 4. contour barrel. I have posted their response below. My takeaway is that the stock wasn't really designed for the No. 4 barrel contour and if you have a HOWA 1500 HS precision with a No. 4 barrel contour and are getting groups larger than you expected, you might want to check the barrel channel for rub marks. If you have rub marks, it seems they are recommending you sand/inlet the stock to you heart's content.

"The PSS139 stock you have was actually designed initially for the Howa #2 contour, but we also have seen that stock install on the larger sporter barrels as well. Even though it free-floats initially, with the wear marks you are seeing, it is making contact when the round is fired. The PSV140 is designed for the #6 Howa contour and would work for your barrel, but you would have a rather large gap (free-float) around the barrel.

What I would do....I would take some 120 grit sandpaper and wrap it around a dowel or hard tubing (that is about the size of your barrel) and sand out (inlet) the barrel channel wherever there are rub marks. You will not change the structural integrity of the stock and you will not contact the aluminum block in the forend. Once you have removed the amount you want, re-install the barreled action and shoot it several times. Remove the stock and see if there are any more rub marks showing. If so, remove more material until no rub marks appear.

Hopefully that will tighten up those groups.

Thank you and have a good day!"

"The PSS139 stock you have was actually designed initially for the Howa #2 contour, but we also have seen that stock install on the larger sporter barrels as well. Even though it free-floats initially, with the wear marks you are seeing, it is making contact when the round is fired. The PSV140 is designed for the #6 Howa contour and would work for your barrel, but you would have a rather large gap (free-float) around the barrel.

What I would do....I would take some 120 grit sandpaper and wrap it around a dowel or hard tubing (that is about the size of your barrel) and sand out (inlet) the barrel channel wherever there are rub marks. You will not change the structural integrity of the stock and you will not contact the aluminum block in the forend. Once you have removed the amount you want, re-install the barreled action and shoot it several times. Remove the stock and see if there are any more rub marks showing. If so, remove more material until no rub marks appear.

Hopefully that will tighten up those groups.

Thank you and have a good day!"

Last edited:

Hey Mike, any updates?Update: For anyone interested, HS Precision responded today to my inquiry about the suitability of the PSS139 for HOWA 1500 rifles with a No. 4. contour barrel. I have posted their response below. My takeaway is that the stock wasn't really designed for the No. 4 barrel contour and if you have a HOWA 1500 HS precision with a No. 4 barrel contour and are getting groups larger than you expected, you might want to check the barrel channel for rub marks. If you have rub marks, it seems they are recommending you sand/inlet the stock to you heart's content.

"The PSS139 stock you have was actually designed initially for the Howa #2 contour, but we also have seen that stock install on the larger sporter barrels as well. Even though it free-floats initially, with the wear marks you are seeing, it is making contact when the round is fired. The PSV140 is designed for the #6 Howa contour and would work for your barrel, but you would have a rather large gap (free-float) around the barrel.

What I would do....I would take some 120 grit sandpaper and wrap it around a dowel or hard tubing (that is about the size of your barrel) and sand out (inlet) the barrel channel wherever there are rub marks. You will not change the structural integrity of the stock and you will not contact the aluminum block in the forend. Once you have removed the amount you want, re-install the barreled action and shoot it several times. Remove the stock and see if there are any more rub marks showing. If so, remove more material until no rub marks appear.

Hopefully that will tighten up those groups.

Thank you and have a good day!"

How'd it go?

Hey Mike, any updates?

How'd it go?

Yes. Since I opened up the barrel channel and bedded the action the 5-shot groups I was getting have shrunk considerably. I am getting 5-shot groups that are around 0.3-0.5" smaller than before with the same powder charge and same bullet. My 5-shot group size right now is right around 1" at 100 yards which is better than the 3-shot 1 MOA guarantee. So I'm pretty happy. I really think the problem was the fact that the HOWA HS Precision with a 26" barrel is a semi-heavy barrel in a stock designed for a sporter barrel profile and it just didn't have enough clearance to be truly free-floated. I will be testing out some flat base bullets soon (before I was just shooting BTHPs) and we'll see how the rifle likes those. Some say they find they are more accurate at short range than BTHPs.

Last edited:

You could saved so much time if you had done what we suggested from the start, which is the same thing HS ended up telling you to do.Yes. Since I opened up the barrel channel and bedding the action the 5-shot groups I was getting have shrunk considerably. I am getting 5-shot groups that are around 0.3-0.5" smaller than before with the same powder charge and same bullet. My 5-shot group size right now is right around 1" at 100 yards which is better than the 3-shot 1 MOA guarantee. So I'm pretty happy. I really think the problem was the fact that the HOWA HS Precision with a 26" barrel is a semi-heavy barrel in a stock designed for a sporter barrel profile and it just didn't have enough clearance to be truly free-floated. I will be testing out some flat base bullets soon (before I was just shooting BTHPs) and we'll see how the rifle likes those. Some say they find they are more accurate at short ranges than BTHPs.

That's true Pirate but I did do what you guys suggested after you suggested it and I have only been a firearms owner for about 3 years so I didn't have the experience to know what the best thing to do was, which was why I asked. Unfortunately I wasn't born with an innate knowledge of firearms like yourself.You could saved so much time if you had done what we suggested from the start, which is the same thing HS ended up telling you to do.

The major reason I reached out to HS Precision was so I wouldn't void the warranty on a stock that retails for around $500 and was, by all accounts, likely the main contributor to the accuracy problems I was having. Maybe $500 isn't much to some but to me it is a lot of money to potentially lose.

Last edited:

Don't mind old 308Pirate, I've been assured he's an old softy at heart with some mommy issues.That's true Pirate but I did do what you guys suggested after you suggested it and I have only been a firearms owner for about 3 years so I didn't have the experience to know what the best thing to do was, which was why I asked. Unfortunately I wasn't born with an innate knowledge of firearms like yourself.

The major reason I reached out to HS Precision was so I wouldn't void the warranty on a stock that retails for around $500 and was, by all accounts, likely the main contributor to the accuracy problems I was having. Maybe $500 isn't much to some but to me it is a lot of money to potentially lose.

Give him some leeway on account of his adult diaper causes occasional irritation to his Prince Albert piercing which puts him in a foul mood.

Update: I kept on trying different things to get the gun to shoot to the sub-MOA guarantee but couldn't get it to do so consistently. It would sometimes print incredible groups (e.g. a 0.3 MOA 5-shot group) but then shoot a 1.5 MOA group with the same ammo. I eventually just decided to sent it in to Legacy Sports in December to see if the could figure it out.

They gave me hell for bedding the action and it took nearly 5 months, but the gunsmith tested it with an unmodified version of the same stock and was getting about 1.5 MOA groups with it. So they sending me a brand new gun. Fingers crossed this one is better. I'll let you guys know how it goes.

They gave me hell for bedding the action and it took nearly 5 months, but the gunsmith tested it with an unmodified version of the same stock and was getting about 1.5 MOA groups with it. So they sending me a brand new gun. Fingers crossed this one is better. I'll let you guys know how it goes.

Last edited:

Chances are it is a shooter. Most people rave about them, including really experienced shooters. I think I just had bad luck. It happens with any manufacturer and I'm not going to hold how long it took against them. The gun industry is crazy right now. At least they tested it properly and are giving me a new gun. That's the best I could have hoped for in terms of an outcome.Haven't shot my 6.5creed yet. Hopefully it's a shooter with no issues.

Hope this new one shoots. There's a lot to like about the HOWA 1500 action. It has a lot of solid features that aren't found on guns that cost several times more.

Last edited:

I bought the new flag painted version that came complete with scope and bipod from Cabelas using my Cabela Bucks I have been saving. I watched Frank's review on YouTube when he 1st posted it and that sealed the deal. While they did change a couple things on it since his review I hope it still performs the same. Either way I didn't have to spend any direct out of pocket money to get it.Chances are it is a shooter. Most people rave about them, including really experienced shooters. I think I just had bad luck. It happens with any manufacturer and I'm not going to hold how long it took against them. The gun industry is crazy right now. At least they tested it properly and are giving me a new gun. That's the best I could have hoped for in terms of an outcome.

Hope this new one shoots. There's a lot to like about the HOWA 1500 action. It has a lot of solid features that aren't found on guns that cost several times more.

1st thing I'm doing before I shoot it is get it painted I don't care for the flag design.

Nice. Free is a good price! I really like the HOWA 1500. It has a 3 position safety, a very good trigger (I would say much better than my other rifle which is a Bergara B14 HMR), bolt and bolt handle machined from a single piece of metal (not welded on), recoil lug integral to the receiver (i.e. the recoil lug isn't a separate piece like on most rifles). It even has the front action screw go right through the front recoil lug which is a really smart idea. It even has the ability to take the firing pin out for cleaning without an tools in about 5 seconds.I bought the new flag painted version that came complete with scope and bipod from Cabelas using my Cabela Bucks I have been saving. I watched Frank's review on YouTube when he 1st posted it and that sealed the deal. While they did change a couple things on it since his review I hope it still performs the same. Either way I didn't have to spend any direct out of pocket money to get it.

1st thing I'm doing before I shoot it is get it painted I don't care for the flag design.

As far as the rifle action goes, the 1500 is the best overall factory action of any design in the world at the moment.Nice. Free is a good price! I really like the HOWA 1500. It has a 3 position safety, a very good trigger (I would say much better than my other rifle which is a Bergara B14 HMR), bolt and bolt handle machined from a single piece of metal (not welded on), recoil lug integral to the receiver (i.e. the recoil lug isn't a separate piece like on most rifles). It even has the front action screw go right through the front recoil lug which is a really smart idea. It even has the ability to take the firing pin out for cleaning without an tools in about 5 seconds.

I know a lot of guys are going to laugh but, they are simple, well made, smooth & cycle flawlessly every time. As long as I don't short stroke the bolt, my Howa absolutely never fails to cycle properly in demanding field conditions. For a hunting rifle, the 1500 is perfectly adequate & most guys wouldn't notice any issues. The one short coming of the Howa is or can be the factory hammer forged barrel. Hammer forged barrels give excellent durability but they just don't seem to do as well as buttoned or cut rifled barrels when tightest repeatability is wanted. Although they usually perform perfectly adequately for the most part, they normally aren't the fabled 1/2 MOA that guys believe is something all rifles can & should be straight off the gun store shelf.

As with most factory rifles, if you're chasing the best accuracy, you generally find the greatest gains if the factory barrel is swapped out for a good quality cut or buttoned unit.

I have my 1500 mounted in an MDT ACC. I'm using the poly-metal mags which have performed flawlessly from the start. If I were to change to a custom action, I simply wouldn't see any benefit from a functional perspective as the 1500 action functions at 100% all the time. Now that I have a heavy contoured target barrel, the rifle repeatability has improved markedly from the small sample numbers so far. I haven't had a chance to undertake any solid testing as yet but, that will come however, the initial samples I have shot are under 1/2 MOA but nowhere near the sample numbers to make a solid determination on the true repeatability.

The accuracy or repeatability of nearly all factory rifles is virtually never going to be less than 1 MOA on an ongoing average basis so, I really wouldn't get too tied up about the odd 1.5" group. If you're getting 1 MOA average with 5 or more shot groups, be content because according to those guys who test shoot rifles for a living, 1 to 1.5 MOA is the reality regardless of what the crowd says.

Bergara was the other one I was looking into also but went for the Howa.Nice. Free is a good price! I really like the HOWA 1500. It has a 3 position safety, a very good trigger (I would say much better than my other rifle which is a Bergara B14 HMR), bolt and bolt handle machined from a single piece of metal (not welded on), recoil lug integral to the receiver (i.e. the recoil lug isn't a separate piece like on most rifles). It even has the front action screw go right through the front recoil lug which is a really smart idea. It even has the ability to take the firing pin out for cleaning without an tools in about 5 seconds.

If I was going for absolute groups I would grab the other one. I just really wanted to see how well this one does.

Attachments

Last edited:

Looks like a nice rifle setup! Yeah. I doubt you'll be displeased with the HOWA. They are great actions like I said. The best I've seen in an off-the-shelf mass-produced rifle. Let me know how she shoots. Mine seemed to like Sierra BTHPs but my rifle was in 308.Bergara was the other one I was looking into also but went for the Howa.

If I was going for absolute groups I would grab the other one. I just really wanted to see how well this one does.

I would agree. I got my HOWA 1500 HS Precision in 308 for $650 too. A steal of a deal when you consider that the stock alone has an MSRP of about $500. Quite frankly with all the machining involved I don't know how they sold them so cheaply. For example the recoil lug is integral to the receiver and the bolt handle is integral to the bolt body. Most companies have a bolt body and weld on the handle. Tikka has a little tab in the stock for a recoil lug, it's a separate part on the Remington 700 action too. Anyway, it's a really bomb-proof no-compromises action design and for the price it's hard to go wrong.As far as the rifle action goes, the 1500 is the best overall factory action of any design in the world at the moment.

I know a lot of guys are going to laugh but, they are simple, well made, smooth & cycle flawlessly every time. As long as I don't short stroke the bolt, my Howa absolutely never fails to cycle properly in demanding field conditions. For a hunting rifle, the 1500 is perfectly adequate & most guys wouldn't notice any issues. The one short coming of the Howa is or can be the factory hammer forged barrel. Hammer forged barrels give excellent durability but they just don't seem to do as well as buttoned or cut rifled barrels when tightest repeatability is wanted. Although they usually perform perfectly adequately for the most part, they normally aren't the fabled 1/2 MOA that guys believe is something all rifles can & should be straight off the gun store shelf.

As with most factory rifles, if you're chasing the best accuracy, you generally find the greatest gains if the factory barrel is swapped out for a good quality cut or buttoned unit.

I have my 1500 mounted in an MDT ACC. I'm using the poly-metal mags which have performed flawlessly from the start. If I were to change to a custom action, I simply wouldn't see any benefit from a functional perspective as the 1500 action functions at 100% all the time. Now that I have a heavy contoured target barrel, the rifle repeatability has improved markedly from the small sample numbers so far. I haven't had a chance to undertake any solid testing as yet but, that will come however, the initial samples I have shot are under 1/2 MOA but nowhere near the sample numbers to make a solid determination on the true repeatability.

The accuracy or repeatability of nearly all factory rifles is virtually never going to be less than 1 MOA on an ongoing average basis so, I really wouldn't get too tied up about the odd 1.5" group. If you're getting 1 MOA average with 5 or more shot groups, be content because according to those guys who test shoot rifles for a living, 1 to 1.5 MOA is the reality regardless of what the crowd says.

Sure mine shot around 1.5 MOA but for most people using it for hunting or plinking that's no problem, especially for the price. Like you said, it's hard to find a stock factory rifle that shoots well under an MOA. 1.5 is fine for most people. I was just interested in shooting as small groups as I possibly could which is why I sent it back to Legacy Sports to have it looked at. At least they are replacing it and making it right.

That's a very good point. Thanks for sharing. The throat was quite long on my HOWA. I just sucked it up and usually single loaded them (because they were too long to seat in the internal magazine)...Obviously not ideal. In an case it didn't make enough of difference in my case to meet their 1 MOA guarantee. That said, I suppose if the throat is long enough you may need to seat so far out that you don't get a good "grip" on the bullet and get inconsistent velocities...Interesting...It has been my experince with Howa's and Ruger's if they just wont shoot and my handloads are not working it is a throat issue. Normaly what I find is that the throat is too long.

Rechambering solves the issue. If the magazine is long enough that is not an issue

Your experience being a sample size of one?It has been my experince with Howa's and Ruger's if they just wont shoot and my handloads are not working it is a throat issue. Normaly what I find is that the throat is too long.

Rechambering solves the issue. If the magazine is long enough that is not an issue

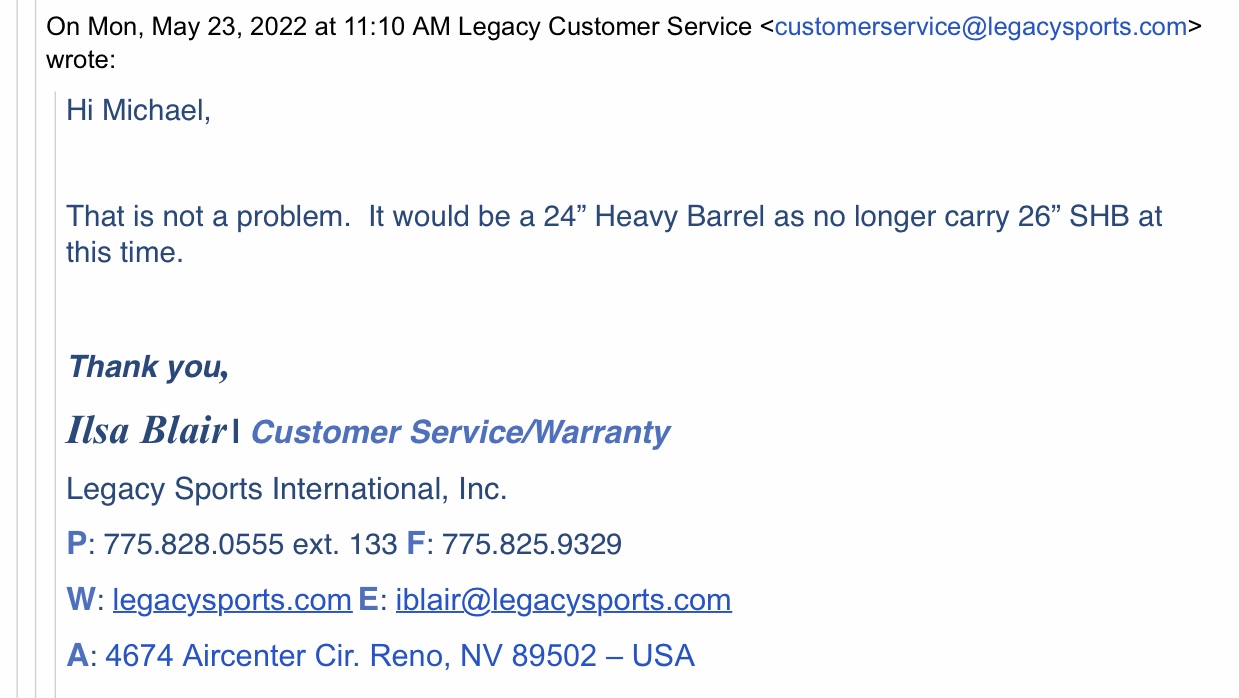

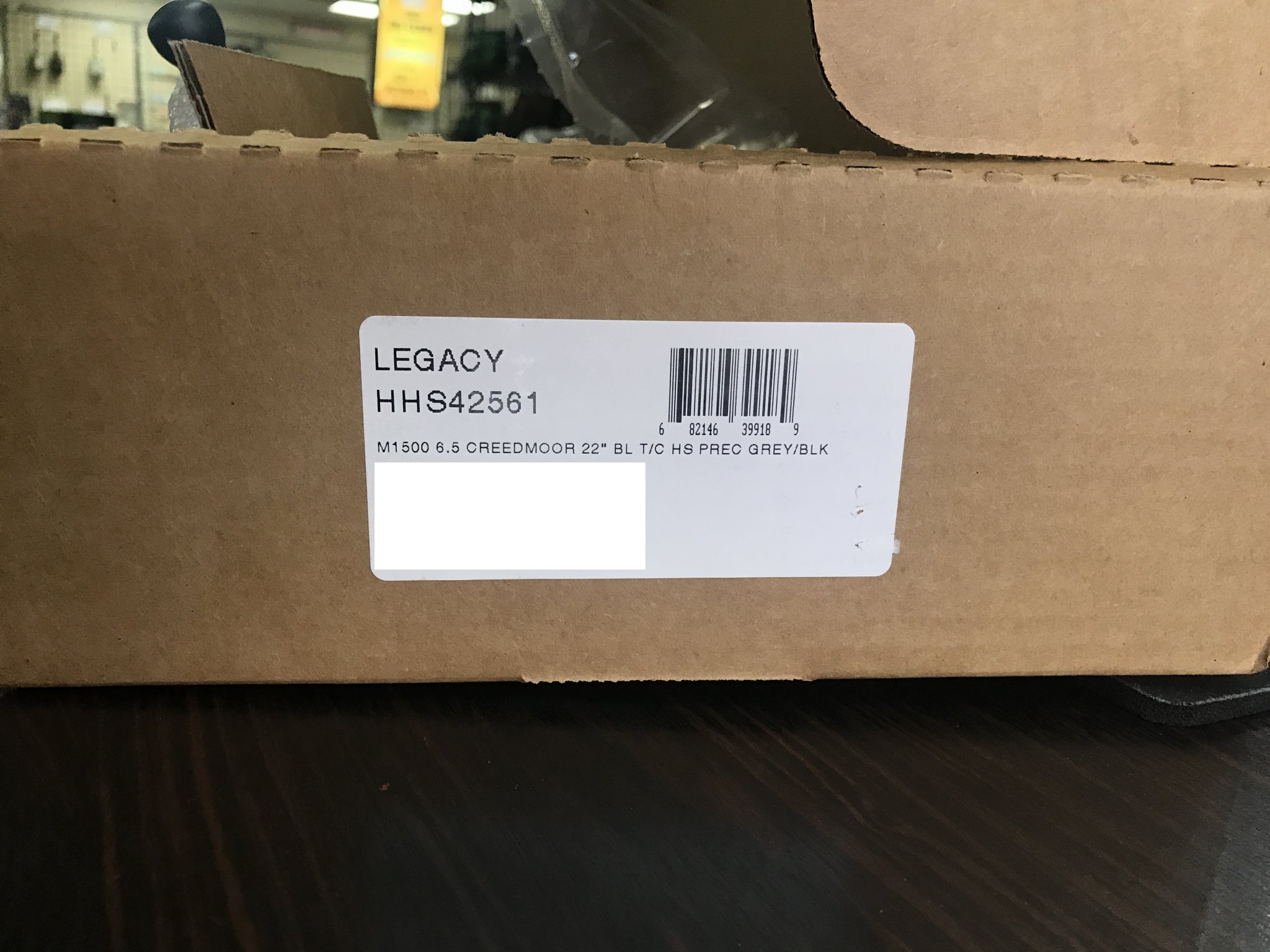

Update: The drama continues. Today I got a call from my FFL that the gun had arrived and was ready to be picked up. Turns out the sent the wrong gun. Legacy Sports told me they were sending me a rifle with a 24" Heavy Barrel because they no longer produce the 26" Semi-Heavy barrel variant they were replacing. I said fine because it's as close as I could get to what I had before. The one I received had a 22" standard barrel. LOL. It took them 5 months to even look at the thing (they said the wind had been too bad to do accuracy testing...For 5 months...Right...I was born at night but it wasn't last night...) and then they sent me the wrong gun. It's not the end of the world though. I realized it wasn't what we agreed on and I didn't accept it. My FFL said they will hold to for me (up to 30 days) while I work it out with them. When I got home I e-mailed them about it. I'll update this thread with what happens next.

What they said they were sending...

What they actually sent (Serial Number Redacted)...

What they said they were sending...

What they actually sent (Serial Number Redacted)...

Last edited:

Update: I told Legacy Sports about the issue. They apologized and admitted they had made a mistake. I asked them if they could give me a HOWA Oryx in an MDT chassis instead of the HOWA HS Precision they sent because the HOWA Oryx comes with a heavy barrel (the HS Precision models no longer come in anything but a standard barrel). They agreed to do it if I paid the price difference between the two models (about $200). That was fair in my book due to the price difference (though not ideal), and I agreed to do it. I would have been much happier if they didn't nickel and dime me here (especially since it took them 5 months to even test the gun and to add insult to injury they sent something completely different from what they told me they were sending). As long as they actually send me the correct model this time that should be the end of this saga.

P.S. The woman handling sending me the new gun seemed like a nice enough person (I spoke to her on the phone) but she said she was new to the company and firearms generally. I can't say that comes as a shock given that she thought a 22" standard profile barrel is effectively the same thing as a 24" heavy profile barrel. I had noticed that their 2022 catalog didn't have the model she was talking about but I figured it must either be an older or newer model because one would assume the sole distributor of this product line in the Country would actually know what they were talking about...Apparently not...Anyway, that's my way of saying that hopefully this is an isolated incident and other people's customer service experience won't be the same.

P.S. The woman handling sending me the new gun seemed like a nice enough person (I spoke to her on the phone) but she said she was new to the company and firearms generally. I can't say that comes as a shock given that she thought a 22" standard profile barrel is effectively the same thing as a 24" heavy profile barrel. I had noticed that their 2022 catalog didn't have the model she was talking about but I figured it must either be an older or newer model because one would assume the sole distributor of this product line in the Country would actually know what they were talking about...Apparently not...Anyway, that's my way of saying that hopefully this is an isolated incident and other people's customer service experience won't be the same.

Last edited:

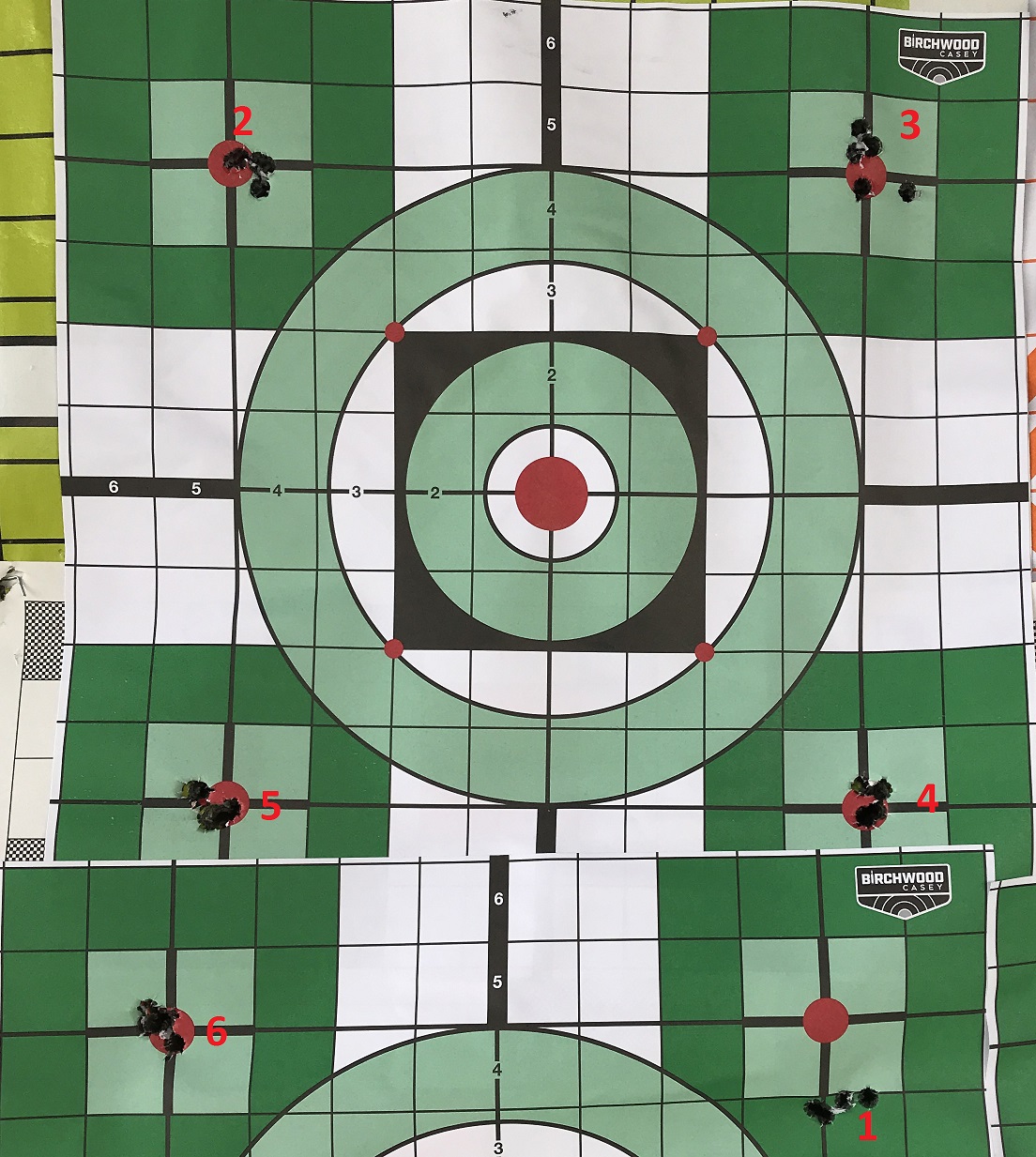

Update: Got the new HOWA Oryx in 6.5 CM. It seems to be shooting pretty good. The 5-shot groups in my test loads have all pretty much been under an inch at 100 yards (which exceeds their 3 shot sub-MOA guarantee obviously). Typical 5-shot powder charge test groups

I even shot this 5-shot group at 100 yards the other week. Going to make some more of those.

I even shot this 5-shot group at 100 yards the other week. Going to make some more of those.

Last edited:

Thank you for this thread MikeHill85!

I recently purchased a Howa HS Precision in 308 and once all of the accessories arrive look forward to getting it to the range.

-Stan

I recently purchased a Howa HS Precision in 308 and once all of the accessories arrive look forward to getting it to the range.

-Stan

No problem Stan,Thank you for this thread MikeHill85!

I recently purchased a Howa HS Precision in 308 and once all of the accessories arrive look forward to getting it to the range.

-Stan

Hope she's a shooter.

Update: Even the new HOWA had problems. There was a deep gash in one of the bolt lugs (there must have been a burr or something on the lug recess) and minimal contact between that bolt lug and the recess. I sent it back to Legacy Sports. They wanted to replace the barreled action but they wouldn't get a replacement in until March. I ended up asking for my money back and Legacy Sports gave me a refund.

I used that money to buy a Tikka CTR Stainless in 6.5 CM. I shot the Tikka for the first time this weekend and you can see the result of the first 30 shots out of the gun below. All of the groups are 5 shots at 100 yards. I labeled the groups in the order I shot them. These groups all have different amounts of powder, working up to the maximum published safe load in 0.3 grain increments. The average group size was 0.57 MOA with the largest being 0.91 MOA and smallest being 0.38 MOA.

The first shots out of the Tikka blow even the optimum loads I developed for my HOWA 1500 out of the water. It might be I just had bad luck with HOWA, good luck with Tikka or some combination of the two. Anyway, it is a night and day difference in consistency and accuracy/precision.

I used that money to buy a Tikka CTR Stainless in 6.5 CM. I shot the Tikka for the first time this weekend and you can see the result of the first 30 shots out of the gun below. All of the groups are 5 shots at 100 yards. I labeled the groups in the order I shot them. These groups all have different amounts of powder, working up to the maximum published safe load in 0.3 grain increments. The average group size was 0.57 MOA with the largest being 0.91 MOA and smallest being 0.38 MOA.

The first shots out of the Tikka blow even the optimum loads I developed for my HOWA 1500 out of the water. It might be I just had bad luck with HOWA, good luck with Tikka or some combination of the two. Anyway, it is a night and day difference in consistency and accuracy/precision.

Last edited:

Had mine out after having the chassis painted to get rid of the flag design. It shot 3/8" at 100 with 142gr. The only issue I have is I didn't wipe it down after shooting it and the next weekend I took it out to shoot again and the scope rings, action and barrel now have rust on them from touching it. I guess that part isn't cerakoted like I thought it was, so I guess it will be going to get that painted now. No biggie just wish I would have known it was a cheep coating cause I would have had them paint that too. I took the muzzle break off and put a thread protector on.

howaguns.com

howaguns.com

Buy Howa American Flag Chassis American Flag Cerakote Bolt Action Rifle - 6.5 Creedmoor - 24in Online – Howa Guns

Buy Howa American Flag Chassis American Flag Cerakote Bolt Action Rifle - 6.5 Creedmoor - 24in online from us and benefit from our discounts for first time

howaguns.com

howaguns.com

Attachments

Glad yours shot for you. For the record, I'm not trying to hate on HOWA. At least they gave me a refund which is something a lot of manufacturers probably wouldn't do. I had a bad experience but a lot of other people love them and say they shoot great.Had mine out after having the chassis painted to get rid of the flag design. It shot 3/8" at 100 with 142gr. The only issue I have is I didn't wipe it down after shooting it and the next weekend I took it out to shoot again and the scope rings, action and barrel now have rust on them from touching it. I guess that part isn't cerakoted like I thought it was, so I guess it will be going to get that painted now. No biggie just wish I would have known it was a cheep coating cause I would have had them paint that too. I took the muzzle break off and put a thread protector on.

Buy Howa American Flag Chassis American Flag Cerakote Bolt Action Rifle - 6.5 Creedmoor - 24in Online – Howa Guns

Buy Howa American Flag Chassis American Flag Cerakote Bolt Action Rifle - 6.5 Creedmoor - 24in online from us and benefit from our discounts for first timehowaguns.com

Crazy that it rusted like that. I never had that happen with any of the HOWAs I've owned. Did it rain or something?

I didn't take it that you were hating on Howa I would have done the samething if I was in your shoes. Tikka's are nice and are hitters that's for sure, congrats.

It didn't rain at all, weather was really nice those 2 days shooting it. Like you I never had that rust happen with any of my other guns either. I was just under the assumption that everything was Cerakoted but my guess is mabey only the chassis, unless the action, rings and barrel had a really bad Cerakote job on them. The shop that Cerakoted it asked me if I wanted him to do it when doing the chassis and I said no it has it on it.

It didn't rain at all, weather was really nice those 2 days shooting it. Like you I never had that rust happen with any of my other guns either. I was just under the assumption that everything was Cerakoted but my guess is mabey only the chassis, unless the action, rings and barrel had a really bad Cerakote job on them. The shop that Cerakoted it asked me if I wanted him to do it when doing the chassis and I said no it has it on it.

Similar threads

- Replies

- 8

- Views

- 457

- Replies

- 13

- Views

- 1K