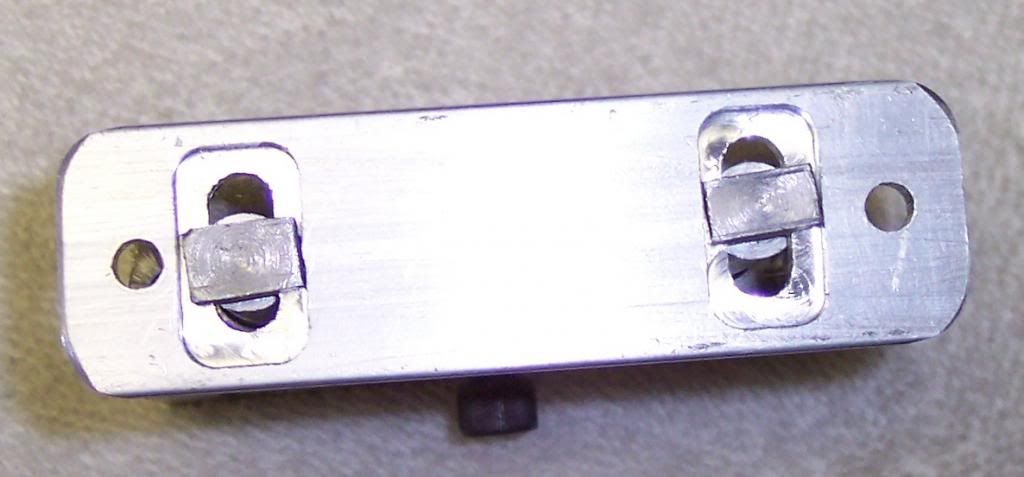

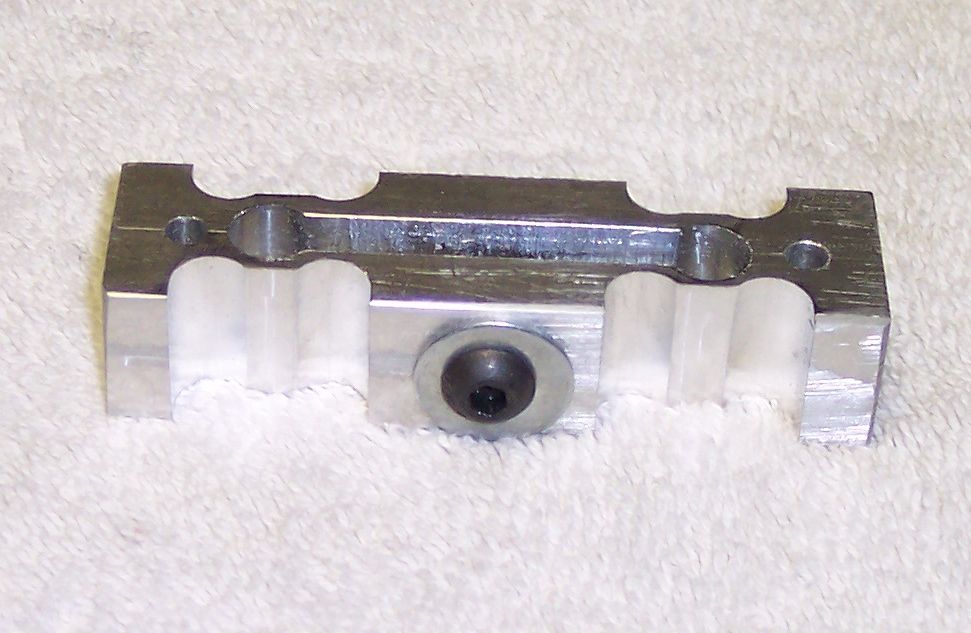

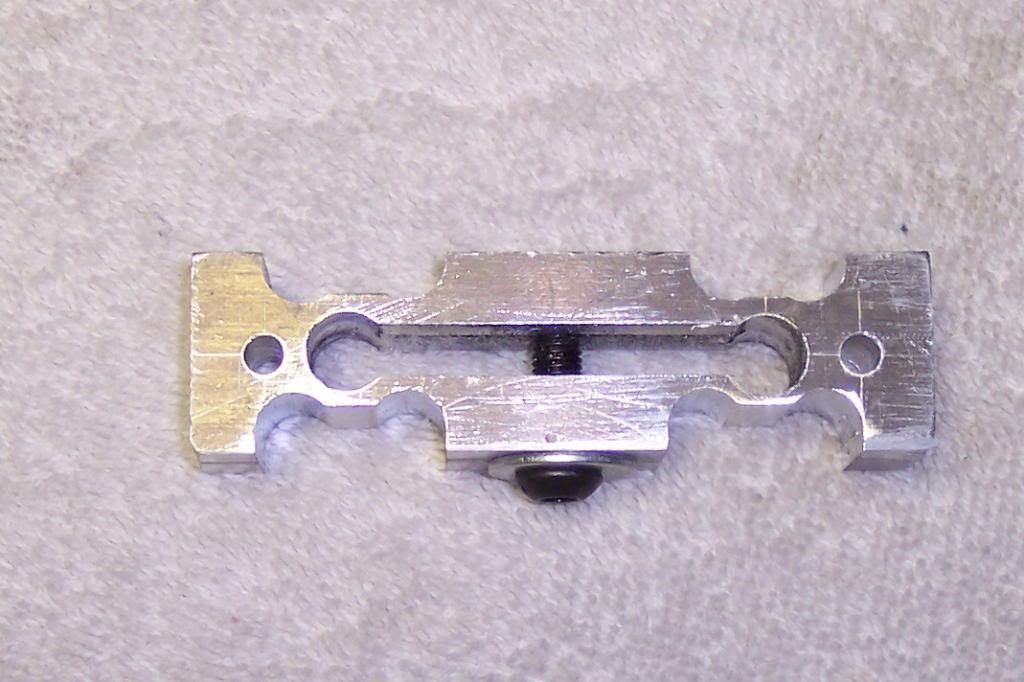

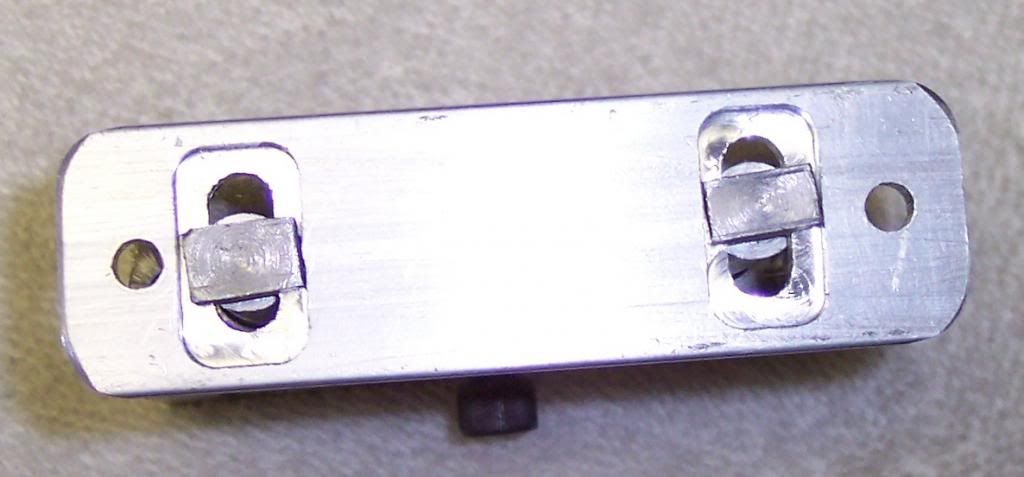

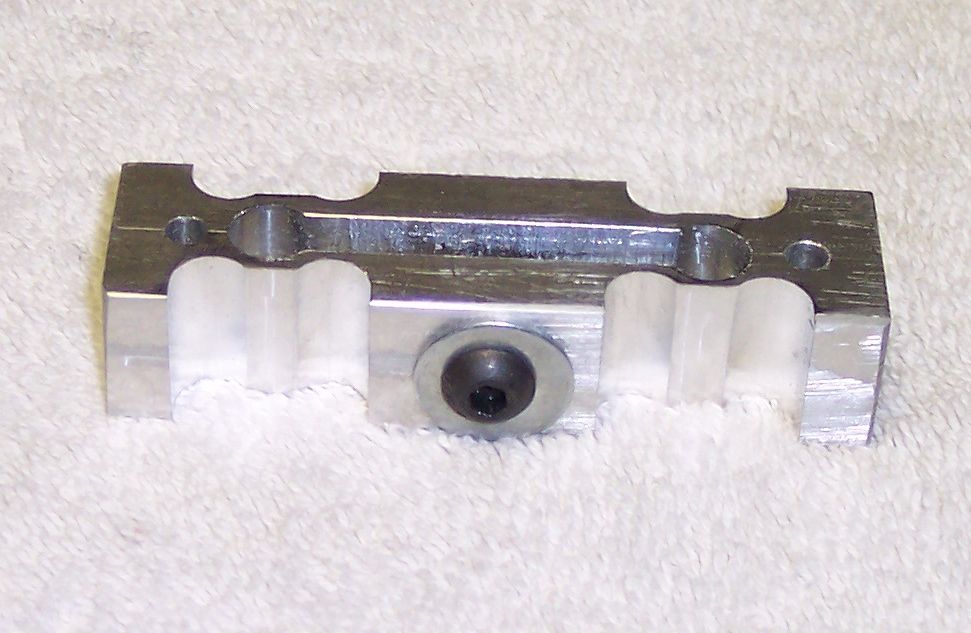

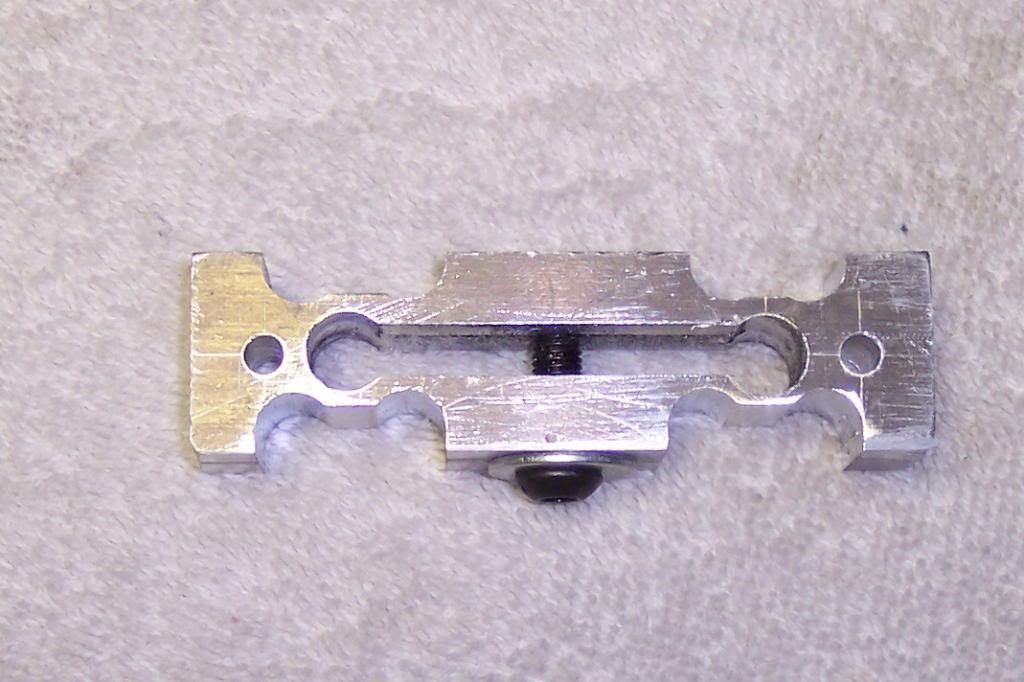

I did a little looking around the web at every design I could find and made these 2 different types of hardware for an adjustable cheek piece. I haven't installed either one yet, but will update this thread when I get around to it. So far I like the one with the plate clamping onto the 3/8" aluminum rods. It doesn't require much force at all to hold tight. The one that just squeezes the rods works fine and is less time consuming to make, but does require a little more force with the allen wrench. Any other thoughts or ideas are welcome.