Been looking at the hawk bullet co. and then Corbin swaging dies. Has anyone have any experience with using there dies and making own bullets? Corbins dies can be custom built to particular ogives with boattails and rebated boattails. Whats the opinion????

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Anyone Swage bullets on here?????

Yes I use Corbin toolsteel dies and my own tool steel dies also.

I am not sure If Corbins will make unusual ogive shapes.

There is little advantage in a non standard ogive shape that is in between two standard shapes.

You have two Corbin companies to choose from now. The original Corbin's run by Dave Corbin and RCE run by Richard Corbin. Try them both and see what they can offer.

They do make rebated boattail dies.

Hawks site has some inaccuracies on it . One example is the statement that softer jackets have half the barrel friction of hard jackets.

That is just plain wrong. Softer the jacket the more the lands will engrave and the more copper fouling will happen and will increase friction .

However a soft jacket does help a game bullet hold together better on impact.

For game bullets the best solution is "core bonding " using the heat gun , solder method . This makes a bonded core bullet and anneals the jacket at the same time.

For target bullets bonding is not advised as it usually decreases accuracy but not always.

To reduce fouling from dead soft jackets you can coat the bullet with Moly or CBN.

Yes I use Corbin toolsteel dies and my own tool steel dies also.

I am not sure If Corbins will make unusual ogive shapes.

There is little advantage in a non standard ogive shape that is in between two standard shapes.

You have two Corbin companies to choose from now. The original Corbin's run by Dave Corbin and RCE run by Richard Corbin. Try them both and see what they can offer.

They do make rebated boattail dies.

Hawks site has some inaccuracies on it . One example is the statement that softer jackets have half the barrel friction of hard jackets.

That is just plain wrong. Softer the jacket the more the lands will engrave and the more copper fouling will happen and will increase friction .

However a soft jacket does help a game bullet hold together better on impact.

For game bullets the best solution is "core bonding " using the heat gun , solder method . This makes a bonded core bullet and anneals the jacket at the same time.

For target bullets bonding is not advised as it usually decreases accuracy but not always.

To reduce fouling from dead soft jackets you can coat the bullet with Moly or CBN.

Re: Anyone Swage bullets on here?????

I was just thinking about this myself and wondering how hard it would be. Hawk is selling dies on Ebay for about 140 bucks but they can't make anything other than half-jacketed soft points. For rifle calibers I don't know why I'd bother at that point, just used hard cast with a gas check.

Good to know about Corbin being able to do BT's I'm going to check that out.

I was told by the owner of Hawk that Berger has cornered the jacket market. What do jackets really cost (he's charging about 10cents each) and I want to see if I can make my own but I don't know what the process is.

I wonder if Berger would sell just jackets to me instead of having to get them through Hawk.

I was just thinking about this myself and wondering how hard it would be. Hawk is selling dies on Ebay for about 140 bucks but they can't make anything other than half-jacketed soft points. For rifle calibers I don't know why I'd bother at that point, just used hard cast with a gas check.

Good to know about Corbin being able to do BT's I'm going to check that out.

I was told by the owner of Hawk that Berger has cornered the jacket market. What do jackets really cost (he's charging about 10cents each) and I want to see if I can make my own but I don't know what the process is.

I wonder if Berger would sell just jackets to me instead of having to get them through Hawk.

Re: Anyone Swage bullets on here?????

I purchased a set of dies and swaging press from Richard Corbin about a year ago and am just getting around to getting it set up. The set up is not hard, work got in the way.

Give yourself 6-12 months of lead time between when you want the equipment and when you order it as die makers seem to run a backlog of 6-12 months. Besides the Corbins there are at least two other die makers that come to mind Blackmon and Niemi I do not have any contact information. A good source of info on swaging is on the forums at saubier.com.

You probably will not save any money on bullets by swaging as the equipment layout is reasonably hefty.

Berger will sell you jackets directly and they seem to run about 8-10 cents a piece.

Hope this helps, I can keep people updated as I start to swage bullets in the near future if anyone is interested.

I purchased a set of dies and swaging press from Richard Corbin about a year ago and am just getting around to getting it set up. The set up is not hard, work got in the way.

Give yourself 6-12 months of lead time between when you want the equipment and when you order it as die makers seem to run a backlog of 6-12 months. Besides the Corbins there are at least two other die makers that come to mind Blackmon and Niemi I do not have any contact information. A good source of info on swaging is on the forums at saubier.com.

You probably will not save any money on bullets by swaging as the equipment layout is reasonably hefty.

Berger will sell you jackets directly and they seem to run about 8-10 cents a piece.

Hope this helps, I can keep people updated as I start to swage bullets in the near future if anyone is interested.

Re: Anyone Swage bullets on here?????

Years ago I bought a kit from Corbin that makes 22 cal jackets out of fired 22 rimfire caseings. Got a core mold and a set of dies and I have .224 bullets with a cool little headstamp on the base.

Years ago I bought a kit from Corbin that makes 22 cal jackets out of fired 22 rimfire caseings. Got a core mold and a set of dies and I have .224 bullets with a cool little headstamp on the base.

Re: Anyone Swage bullets on here?????

We were in business for several years making benchrest bullets. Here's the link to an old web page: www.johnsonprecision.net DO NOT write or call the numbers on that website. I get tired of cleaning the calls off my garage phone. And that email has been dead for years.

If you want something better than what you can buy, it'll take you $12K and a lot of elbow grease for 1 style / caliber bullet. Then $5K for each style after the first. If you're not that serious just buy Bergers. Some custom makers can't make them as good as Bergers.

We were in business for several years making benchrest bullets. Here's the link to an old web page: www.johnsonprecision.net DO NOT write or call the numbers on that website. I get tired of cleaning the calls off my garage phone. And that email has been dead for years.

If you want something better than what you can buy, it'll take you $12K and a lot of elbow grease for 1 style / caliber bullet. Then $5K for each style after the first. If you're not that serious just buy Bergers. Some custom makers can't make them as good as Bergers.

Re: Anyone Swage bullets on here?????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Victor N TN</div><div class="ubbcode-body">We were in business for several years making benchrest bullets. Here's the link to an old web page: www.johnsonprecision.net DO NOT write or call the numbers on that website. I get tired of cleaning the calls off my garage phone. And that email has been dead for years.

If you want something better than what you can buy, it'll take you $12K and a lot of elbow grease for 1 style / caliber bullet. Then $5K for each style after the first. If you're not that serious just buy Bergers. Some custom makers can't make them as good as Bergers. </div></div>

You can make a bullet just as good as any manufacturer using tool steel dies and quality jackets like J4's.

It does not cost anything like 12K for a home swaging system.

Berger has not cornered the jacket market but it does make J'4s which are one of the best for loose core target bullets and also make a thick jacket now to resist blow up.

You can buy jackets from CH tool and die , Sierra , Corbins and many custom makers also.

Berger does have some advantage because it grabs all the most concentric jackets for its own production first and we get whats left over.

Custom makers can make just as good a bullet as Berger can if they get good jackets . Infact Berger is the only brand that I found several poped jackets in numerous box's of bullets.

I have never found a poped jacket in a Sierra bullet. So Berger is not perfect and neither are any of the others.

Don't buy secondhand swaging dies unless you know who owned them and are sure they are still good.

It only takes a few thou wear in the core seater and the close tolerance is lost causing ejection problems in the point former.

Half jacket bullets are not suitable for most modern high velocity rifle cartridges .

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Victor N TN</div><div class="ubbcode-body">We were in business for several years making benchrest bullets. Here's the link to an old web page: www.johnsonprecision.net DO NOT write or call the numbers on that website. I get tired of cleaning the calls off my garage phone. And that email has been dead for years.

If you want something better than what you can buy, it'll take you $12K and a lot of elbow grease for 1 style / caliber bullet. Then $5K for each style after the first. If you're not that serious just buy Bergers. Some custom makers can't make them as good as Bergers. </div></div>

You can make a bullet just as good as any manufacturer using tool steel dies and quality jackets like J4's.

It does not cost anything like 12K for a home swaging system.

Berger has not cornered the jacket market but it does make J'4s which are one of the best for loose core target bullets and also make a thick jacket now to resist blow up.

You can buy jackets from CH tool and die , Sierra , Corbins and many custom makers also.

Berger does have some advantage because it grabs all the most concentric jackets for its own production first and we get whats left over.

Custom makers can make just as good a bullet as Berger can if they get good jackets . Infact Berger is the only brand that I found several poped jackets in numerous box's of bullets.

I have never found a poped jacket in a Sierra bullet. So Berger is not perfect and neither are any of the others.

Don't buy secondhand swaging dies unless you know who owned them and are sure they are still good.

It only takes a few thou wear in the core seater and the close tolerance is lost causing ejection problems in the point former.

Half jacket bullets are not suitable for most modern high velocity rifle cartridges .

Re: Anyone Swage bullets on here?????

Bullets made from rimfire cases generally never attain the same accuracy as bullets made from good quality new jackets.

The firing pin indentation causes problems on the base edge of the bullet in most cases. I used a convex base punch which leaves a concave base on the bullet. This helps stretch the firing pin indentation around away from the base edge.

Annealing the cases before you iron them out will help also.

Even so the best accuracy I ever obtained was about .8 with a 52 grain in a 223. Most hovered around 1 1/4 inch group.

This is not that bad for some casual small game hunting as I have bought cheap bullets in the past that shot no better .

Bullets made from rimfire cases generally never attain the same accuracy as bullets made from good quality new jackets.

The firing pin indentation causes problems on the base edge of the bullet in most cases. I used a convex base punch which leaves a concave base on the bullet. This helps stretch the firing pin indentation around away from the base edge.

Annealing the cases before you iron them out will help also.

Even so the best accuracy I ever obtained was about .8 with a 52 grain in a 223. Most hovered around 1 1/4 inch group.

This is not that bad for some casual small game hunting as I have bought cheap bullets in the past that shot no better .

Re: Anyone Swage bullets on here?????

Thanks to all the guys with a lot of experience for weighing in on the topic.

I'm a little concerned about what the future holds for component availability if the "powers that be" get their way in this country.

I've shot better than 1MOA with gas checked hard cast, I won't push it past 3k and usually keep them under 2700 but they shoot pretty nicely. I was wondering really what would be involved in making high quality long range stuff like VLD's vs. having to pay the government tax explosion that's being rumored.

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, several friends are tool and die makers that like shooting) I could see getting into the project to make bullets at home for friends and family.

Thanks to all the guys with a lot of experience for weighing in on the topic.

I'm a little concerned about what the future holds for component availability if the "powers that be" get their way in this country.

I've shot better than 1MOA with gas checked hard cast, I won't push it past 3k and usually keep them under 2700 but they shoot pretty nicely. I was wondering really what would be involved in making high quality long range stuff like VLD's vs. having to pay the government tax explosion that's being rumored.

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, several friends are tool and die makers that like shooting) I could see getting into the project to make bullets at home for friends and family.

Re: Anyone Swage bullets on here?????

Country;

Yeah, I never got great accuracy either. I did make a good varmint bullet that would blow up at very low velocity using a .22 short case for a jacket and a large exposed lead tip. In the days before the V-max bullets my home spun jobs could take a fox and not leave an exit wound thus preserving the hide.

Another plus is that it does make a bullet and there may be a time (soon) where all components are in short supply or illegal altogether.

Country;

Yeah, I never got great accuracy either. I did make a good varmint bullet that would blow up at very low velocity using a .22 short case for a jacket and a large exposed lead tip. In the days before the V-max bullets my home spun jobs could take a fox and not leave an exit wound thus preserving the hide.

Another plus is that it does make a bullet and there may be a time (soon) where all components are in short supply or illegal altogether.

Re: Anyone Swage bullets on here?????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: vinconco</div><div class="ubbcode-body">Country;

Another plus is that it does make a bullet and there may be a time (soon) where all components are in short supply or illegal altogether.

</div></div>

That is precisely why I'm interested in it for long range high quality stuff. Just for hunting and defense I don't need anything more than a really hard lead and a gas check.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: vinconco</div><div class="ubbcode-body">Country;

Another plus is that it does make a bullet and there may be a time (soon) where all components are in short supply or illegal altogether.

</div></div>

That is precisely why I'm interested in it for long range high quality stuff. Just for hunting and defense I don't need anything more than a really hard lead and a gas check.

Re: Anyone Swage bullets on here?????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body">

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, </div></div>

I dunno bohem..... It is called the "die makers art". I think the polishing to final dimensions is where it gets tricky.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body">

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, </div></div>

I dunno bohem..... It is called the "die makers art". I think the polishing to final dimensions is where it gets tricky.

Re: Anyone Swage bullets on here?????

Yeah, I completely understand some things have an art form to them as well as a science. I'm hoping that my tool and die maker friends can help me out in that regard.

Too many projects, not enough time and money to do them.

Yeah, I completely understand some things have an art form to them as well as a science. I'm hoping that my tool and die maker friends can help me out in that regard.

Too many projects, not enough time and money to do them.

Re: Anyone Swage bullets on here?????

I called the owner of Hawks bullets and talked to him about his swaging dies on Ebay. They are some leftovers from when he bought the business. He told me that he make me a spitzer style closed flat base die in 308 cal. for $155 and a 22 cal. die for $135. These are designed to go into a RCBS or Lyman press and will make a consistent spitzer profile bullet. He told me he shoots his own bullets and that when shooting at 300 hundred with Sierra, Speer, Hornady against his, the difference in performance was not noticable. He said that the terminal ballistics with his bullet usually outperforms most of them. As far as special designs/ogives he said, you tell him what you want and he'll shoot you a price and if you like it he will make it.

I called the owner of Hawks bullets and talked to him about his swaging dies on Ebay. They are some leftovers from when he bought the business. He told me that he make me a spitzer style closed flat base die in 308 cal. for $155 and a 22 cal. die for $135. These are designed to go into a RCBS or Lyman press and will make a consistent spitzer profile bullet. He told me he shoots his own bullets and that when shooting at 300 hundred with Sierra, Speer, Hornady against his, the difference in performance was not noticable. He said that the terminal ballistics with his bullet usually outperforms most of them. As far as special designs/ogives he said, you tell him what you want and he'll shoot you a price and if you like it he will make it.

Re: Anyone Swage bullets on here?????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body">Thanks to all the guys with a lot of experience for weighing in on the topic.

I'm a little concerned about what the future holds for component availability if the "powers that be" get their way in this country.

I've shot better than 1MOA with gas checked hard cast, I won't push it past 3k and usually keep them under 2700 but they shoot pretty nicely. I was wondering really what would be involved in making high quality long range stuff like VLD's vs. having to pay the government tax explosion that's being rumored.

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, several friends are tool and die makers that like shooting) I could see getting into the project to make bullets at home for friends and family. </div></div>

Making dies would be possible if you know something about bullet swaging dies. There is a close relationship between the core seating die and the point forming die . If a raw jacket is say .240 the core seater will be .241 or .242 and the point former .243 or slightly over for a 243 bullet.

You are swaging up as you go along. The core swager will be sized to make a lead core that slips all the way to the bottom of the raw jacket in a J4 jacket before it is core seated.

The Core swager and core seater dies are not that hard to make as they are basicly just a parallel bore. However getting the finished polish in the steel surface without exceeding the final size can be difficult.

The point forming die is the hard one to make as you have to make ogive shaped reamers and lapps . However a CNC machine is just the tool to make those ogive shaped reamers and lapps.

You realy need to decide on what type of dies and press system you are going to use first as their are several types .

I would suggest buying Corbins books on bullet swaging . Rediscover Swaging and Handbook of Bullet Swaging No 8 by Dave Corbin.

This will give you an idea of how to make a tool steel die.

In all honesty mate I think a dedicated purpose built press and die system is the way to go.

Something like a Corbin S press http://www.corbins.com/ or

RCE wallnut hill press http://rceco.com/MN.asp?pg=MetalWHill

Buy a press and one set of dies and then you can copy the dies for other calibers.

You will make a wider variety and better bullets in this type of press compared to a normal reloading press.

In a reloading press you will be limited to the length of bullet and the ogive you can swage because they only have enough leverage for a short distance right at the top of the stroke.

If you look at hawk bullets they have low number ogives and they don't even talk about the ogive shape of any particular bullets. Their hunting type bullets.

If you want to make say a 308 , 150 grain 11 caliber ogive HP ( protected point ) with a rebated boat tail to shoot long range then forget a reloading press and die system.

To form the whole length of the jacket to a long ogive needs the extra leverage of the dedicated swaging press.

For a beginner target shooter I would suggest you start with an 8s ogive point forming die as it will be more forgiving and a medium thickness ejection pin.

If you want a smaller meplat ( Hollow point ) for increased BC then close it a bit more after the bullet is finnished .

Thin ejection pins lead to stuck bullets and broken pins.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body">Thanks to all the guys with a lot of experience for weighing in on the topic.

I'm a little concerned about what the future holds for component availability if the "powers that be" get their way in this country.

I've shot better than 1MOA with gas checked hard cast, I won't push it past 3k and usually keep them under 2700 but they shoot pretty nicely. I was wondering really what would be involved in making high quality long range stuff like VLD's vs. having to pay the government tax explosion that's being rumored.

If it wasn't going to be all that difficult for me to make dies (I have access to a CNC shop and I'm a decent machinist, several friends are tool and die makers that like shooting) I could see getting into the project to make bullets at home for friends and family. </div></div>

Making dies would be possible if you know something about bullet swaging dies. There is a close relationship between the core seating die and the point forming die . If a raw jacket is say .240 the core seater will be .241 or .242 and the point former .243 or slightly over for a 243 bullet.

You are swaging up as you go along. The core swager will be sized to make a lead core that slips all the way to the bottom of the raw jacket in a J4 jacket before it is core seated.

The Core swager and core seater dies are not that hard to make as they are basicly just a parallel bore. However getting the finished polish in the steel surface without exceeding the final size can be difficult.

The point forming die is the hard one to make as you have to make ogive shaped reamers and lapps . However a CNC machine is just the tool to make those ogive shaped reamers and lapps.

You realy need to decide on what type of dies and press system you are going to use first as their are several types .

I would suggest buying Corbins books on bullet swaging . Rediscover Swaging and Handbook of Bullet Swaging No 8 by Dave Corbin.

This will give you an idea of how to make a tool steel die.

In all honesty mate I think a dedicated purpose built press and die system is the way to go.

Something like a Corbin S press http://www.corbins.com/ or

RCE wallnut hill press http://rceco.com/MN.asp?pg=MetalWHill

Buy a press and one set of dies and then you can copy the dies for other calibers.

You will make a wider variety and better bullets in this type of press compared to a normal reloading press.

In a reloading press you will be limited to the length of bullet and the ogive you can swage because they only have enough leverage for a short distance right at the top of the stroke.

If you look at hawk bullets they have low number ogives and they don't even talk about the ogive shape of any particular bullets. Their hunting type bullets.

If you want to make say a 308 , 150 grain 11 caliber ogive HP ( protected point ) with a rebated boat tail to shoot long range then forget a reloading press and die system.

To form the whole length of the jacket to a long ogive needs the extra leverage of the dedicated swaging press.

For a beginner target shooter I would suggest you start with an 8s ogive point forming die as it will be more forgiving and a medium thickness ejection pin.

If you want a smaller meplat ( Hollow point ) for increased BC then close it a bit more after the bullet is finnished .

Thin ejection pins lead to stuck bullets and broken pins.

Re: Anyone Swage bullets on here?????

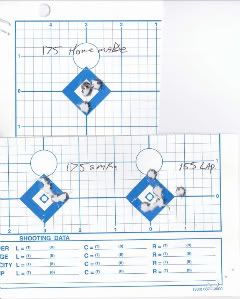

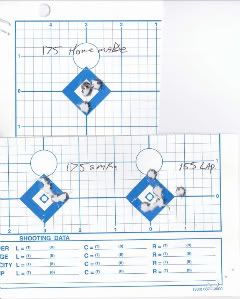

hey guys, i finally got to the range with my new home made bullets. i got the dies and gear from corbin. dave over there is very helpful. i'm making some .308 175g uld rebated boat tails. it took a little bit to get them working, and i still have some things to iron out but this is the first few i made. i need to take some more pictures and scan the up close targets but these pics are 4 or 5 steps, and the 320yds steel. the day was 70f, overcast, 1/2 val wind 10-12 mph from 430. the wind got me a few times and the guy with the 7mag w/ a break next to me. but it was an ok test. the steel is 5rds 175smk on top, and 5rds mine on the bottom, my hand is about 4 inch wide i didn't measure the groups, but they look about the same.

hey guys, i finally got to the range with my new home made bullets. i got the dies and gear from corbin. dave over there is very helpful. i'm making some .308 175g uld rebated boat tails. it took a little bit to get them working, and i still have some things to iron out but this is the first few i made. i need to take some more pictures and scan the up close targets but these pics are 4 or 5 steps, and the 320yds steel. the day was 70f, overcast, 1/2 val wind 10-12 mph from 430. the wind got me a few times and the guy with the 7mag w/ a break next to me. but it was an ok test. the steel is 5rds 175smk on top, and 5rds mine on the bottom, my hand is about 4 inch wide i didn't measure the groups, but they look about the same.

Re: Anyone Swage bullets on here?????

JFK-

That's awesome looking, mind if I ask what you can make the bullets for, jacket cost, equipment cost, etc.? I'm thinking about going this route myself.

How long does it take to make 50 tips when you have everything setup already?

JFK-

That's awesome looking, mind if I ask what you can make the bullets for, jacket cost, equipment cost, etc.? I'm thinking about going this route myself.

How long does it take to make 50 tips when you have everything setup already?

Re: Anyone Swage bullets on here?????

What victor said, It will cost you 12000 to make benchrest quality bullets. I've been talking with Niemi about making me a die set for 338 once berger releases the J4 jackets, If the jackets are good enough the dies will cost 6000 to 6500 the way I want them.

What victor said, It will cost you 12000 to make benchrest quality bullets. I've been talking with Niemi about making me a die set for 338 once berger releases the J4 jackets, If the jackets are good enough the dies will cost 6000 to 6500 the way I want them.

Re: Anyone Swage bullets on here?????

Bohem-

i havn't done the math yet so lets do it now. jackets are $35 for 250, lead wire is also $35 for 10lbs (that about 580 if you make 175s) so if i can do math still thats .08$ each. 175smk are .24$ last time i got them. no if you take add the press, dies, and your time then i'm not sure on the payback. 50 bullets takes about, 30 minutes about. i'll have to look at the clock next time and get a better idea.

let me know if you need anything else.

Bohem-

i havn't done the math yet so lets do it now. jackets are $35 for 250, lead wire is also $35 for 10lbs (that about 580 if you make 175s) so if i can do math still thats .08$ each. 175smk are .24$ last time i got them. no if you take add the press, dies, and your time then i'm not sure on the payback. 50 bullets takes about, 30 minutes about. i'll have to look at the clock next time and get a better idea.

let me know if you need anything else.

Re: Anyone Swage bullets on here?????

got the other stuffed scaned tonight, 3 loads at 100, 175 homemade, 175 smk, 155 lapua. (in that order)

200yds, 3inch OD shoot-n-see. page is turned, shot top and bottom, more wind movement then height.

got the other stuffed scaned tonight, 3 loads at 100, 175 homemade, 175 smk, 155 lapua. (in that order)

200yds, 3inch OD shoot-n-see. page is turned, shot top and bottom, more wind movement then height.

Re: Anyone Swage bullets on here?????

Can you explain the process in detail to us? This looks intriguing.

Can you explain the process in detail to us? This looks intriguing.

Re: Anyone Swage bullets on here?????

well guys i would love to but i don't think i can do it correctly. so lets try these links instead. they may help more.

overview

http://www.corbins.com/fjfb-3.htm

rebated boattails

http://www.corbins.com/rbt.htm

core bound

http://www.corbins.com/corebond.htm

the corbin site has a lot of info you just have to look around for it.

well guys i would love to but i don't think i can do it correctly. so lets try these links instead. they may help more.

overview

http://www.corbins.com/fjfb-3.htm

rebated boattails

http://www.corbins.com/rbt.htm

core bound

http://www.corbins.com/corebond.htm

the corbin site has a lot of info you just have to look around for it.

Re: Anyone Swage bullets on here?????

jfkdiver

That was really informative. I beleive that the first jacketed bullets were made out of .22 casings?

jfkdiver

That was really informative. I beleive that the first jacketed bullets were made out of .22 casings?

Re: Anyone Swage bullets on here?????

The homemade stuff was first made from 22 cases. That's how RCBS was founded and what the Rockchucker was invented for. Swaging 22 and 6mm bullets out of 22LR cases.

I'm looking into a set of those dies for myself, I already started saving 22 cases from last weekend. I've got about 1k jackets ready to go LOL

The homemade stuff was first made from 22 cases. That's how RCBS was founded and what the Rockchucker was invented for. Swaging 22 and 6mm bullets out of 22LR cases.

I'm looking into a set of those dies for myself, I already started saving 22 cases from last weekend. I've got about 1k jackets ready to go LOL

Re: Anyone Swage bullets on here?????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: vinconco</div><div class="ubbcode-body">Years ago I bought a kit from Corbin that makes 22 cal jackets out of fired 22 rimfire caseings. Got a core mold and a set of dies and I have .224 bullets with a cool little headstamp on the base. </div></div>I would LOVE to have this kit, anyone know who would want to sell one or where a guy could get one? I looked, I don't think Corbin still makes 'em.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: vinconco</div><div class="ubbcode-body">Years ago I bought a kit from Corbin that makes 22 cal jackets out of fired 22 rimfire caseings. Got a core mold and a set of dies and I have .224 bullets with a cool little headstamp on the base. </div></div>I would LOVE to have this kit, anyone know who would want to sell one or where a guy could get one? I looked, I don't think Corbin still makes 'em.

Re: Anyone Swage bullets on here?????

I'll try to dig up a link in my email, but I think you can get them for about 400 bucks and they thread into a standard single stage reloading press with 7/8-14 threads. Lemme go look.

EDIT: Corbin still makes the stuff. http://www.corbins.com/prrfjm.htm

I'll try to dig up a link in my email, but I think you can get them for about 400 bucks and they thread into a standard single stage reloading press with 7/8-14 threads. Lemme go look.

EDIT: Corbin still makes the stuff. http://www.corbins.com/prrfjm.htm

Re: Anyone Swage bullets on here?????

This seems like fun. So does it really cost $6k-$12k to set all this equipment up ?

jfkdiver, would you mind letting us know what ur setup cost you to start out, and what you got ?

thanks again

This seems like fun. So does it really cost $6k-$12k to set all this equipment up ?

jfkdiver, would you mind letting us know what ur setup cost you to start out, and what you got ?

thanks again

Re: Anyone Swage bullets on here?????

Padron it depends on what kind of dies you want steel or carbide and what your goal are. If you plan on making "Benchrest Quality bullets" which are a grade above berger, hornady, sierra, etc. yes it is giong to cost you 12,000.

I was talking with Richard Corbin the other day and he is coming out with a video on how to use fired cartridges to make jackets. The video is already shot it just needs editing.

Padron it depends on what kind of dies you want steel or carbide and what your goal are. If you plan on making "Benchrest Quality bullets" which are a grade above berger, hornady, sierra, etc. yes it is giong to cost you 12,000.

I was talking with Richard Corbin the other day and he is coming out with a video on how to use fired cartridges to make jackets. The video is already shot it just needs editing.

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 12

- Views

- 650