I would like to get a feel for what people like using as their go to bedding compound. If anyone can include why, pros, cons, exceptions I think it would be helpful.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Bedding compounds

- Thread starter Jacko Jeebus

- Start date

Re: Bedding compounds

Can't beat marinetex. Great strength, not affected by solvents, no shrinkage, forgiving working time, easy to use. Most smiths use it for those very reasons

Can't beat marinetex. Great strength, not affected by solvents, no shrinkage, forgiving working time, easy to use. Most smiths use it for those very reasons

Re: Bedding compounds

I prefer Devcon 10110.

I like it mainly because of its consistency - it is just a bit thinner than peanut butter, and therefore doesn't run. If you have a void to fill, or need the epoxy to sag into a crevice, the Devcon ISN'T the answer, but for most typical bedding jobs, I find the no-sag characteristic easier to work with.

Mechanically, both marine tex and Devcon will do the job nicely.

I prefer Devcon 10110.

I like it mainly because of its consistency - it is just a bit thinner than peanut butter, and therefore doesn't run. If you have a void to fill, or need the epoxy to sag into a crevice, the Devcon ISN'T the answer, but for most typical bedding jobs, I find the no-sag characteristic easier to work with.

Mechanically, both marine tex and Devcon will do the job nicely.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I prefer Devcon 10110.</div></div>

+1 the stuff works well. I have had very good luck with JBWeld as well for bedding scope bases (only thing so far I have tried JBWeld on) it worked as well as Devcon.

I have a base that I bedded with both (Devcon in front and JBWeld in back). Aside from the color, I cannot tell the difference between the finished product.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I prefer Devcon 10110.</div></div>

+1 the stuff works well. I have had very good luck with JBWeld as well for bedding scope bases (only thing so far I have tried JBWeld on) it worked as well as Devcon.

I have a base that I bedded with both (Devcon in front and JBWeld in back). Aside from the color, I cannot tell the difference between the finished product.

Re: Bedding compounds

Devcon all the way. The steel content gives it great shock resistance yet is not brittle. A bit on the stiff side but can be worked into crevices, great adhesion.

The only drawback is it has so much steel in it it can rust.

I have heard (but cannot substantiate) of Bisonite and Marinetex getting brittle with age.

Devcon all the way. The steel content gives it great shock resistance yet is not brittle. A bit on the stiff side but can be worked into crevices, great adhesion.

The only drawback is it has so much steel in it it can rust.

I have heard (but cannot substantiate) of Bisonite and Marinetex getting brittle with age.

Re: Bedding compounds

Ive used devcon for 2 stocks, both worked great! I really like how you can get the idea what this product is capable of just by looking and working with it. Thick and easily usable for the new guy, not runny like some others, and you can see the metal in it.

You just know your about to use some good stuff once you start working with it.

Other than that I have used JB weld for scope bases and that works wonders.

This and some Kiwi neutral shoe polish and your good to go

Ive used devcon for 2 stocks, both worked great! I really like how you can get the idea what this product is capable of just by looking and working with it. Thick and easily usable for the new guy, not runny like some others, and you can see the metal in it.

You just know your about to use some good stuff once you start working with it.

Other than that I have used JB weld for scope bases and that works wonders.

This and some Kiwi neutral shoe polish and your good to go

Re: Bedding compounds

I like the Pro bed 2000 epoxy it flows nicely but its not saggy. I real like the 1 to 1 mixing ratio. The kits and tools that Charley manufactures at Score High makes the job of bedding very easy. If your just starting out doing your own gunsmithing have questions his instructions are hard to beat.

I like the Pro bed 2000 epoxy it flows nicely but its not saggy. I real like the 1 to 1 mixing ratio. The kits and tools that Charley manufactures at Score High makes the job of bedding very easy. If your just starting out doing your own gunsmithing have questions his instructions are hard to beat.

Re: Bedding compounds

I recently tried Devcon for the first time- I went with the aluminum compound. I've bedded two Seekins bases and two Seekins SRS Rails so far. Good stuff. Plenty of work time for me on these projects, has a long enough cure time that a few hours in I was able to remove the part, trim up what needed trimming with a razor and set back in place. Seemed to me that the Aluminum compound would do just fine considering it is adhering to the aluminum product, not the steel. But I am aware the steel product seems to be the go-to stuff.

I used JB Weld on a previous base bedding and it worked fine.

I'm looking forward to trying out skim bedding my HS precision stocks after all the smithing work is done on my twin's (.308 and .223 , 20" 5-R's)

I recently tried Devcon for the first time- I went with the aluminum compound. I've bedded two Seekins bases and two Seekins SRS Rails so far. Good stuff. Plenty of work time for me on these projects, has a long enough cure time that a few hours in I was able to remove the part, trim up what needed trimming with a razor and set back in place. Seemed to me that the Aluminum compound would do just fine considering it is adhering to the aluminum product, not the steel. But I am aware the steel product seems to be the go-to stuff.

I used JB Weld on a previous base bedding and it worked fine.

I'm looking forward to trying out skim bedding my HS precision stocks after all the smithing work is done on my twin's (.308 and .223 , 20" 5-R's)

Re: Bedding compounds

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot.

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot.

Re: Bedding compounds

A couple months ago I did my first bedding job on an old Remington 700. I went with the Score High system and used their bedding compound. I was very pleased with the working texture and time. The job turned out great. Other than that, the DevCon 10110 seems to be the standard material.

A couple months ago I did my first bedding job on an old Remington 700. I went with the Score High system and used their bedding compound. I was very pleased with the working texture and time. The job turned out great. Other than that, the DevCon 10110 seems to be the standard material.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: stockdoc</div><div class="ubbcode-body">Can't beat marinetex. Great strength, not affected by solvents, no shrinkage, forgiving working time, easy to use. Most smiths use it for those very reasons </div></div>

+100.........marine tex is what i use, it works great.......just make sure you use plenty of release agent (kiwi neutral shoe polish)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: stockdoc</div><div class="ubbcode-body">Can't beat marinetex. Great strength, not affected by solvents, no shrinkage, forgiving working time, easy to use. Most smiths use it for those very reasons </div></div>

+100.........marine tex is what i use, it works great.......just make sure you use plenty of release agent (kiwi neutral shoe polish)

Re: Bedding compounds

Devcon(all the metallic based epoxies), ProBed 2k, Marine Tex Grey, and AcraGlass are the most popular ones out there. I have heard some use industrial boiler epoxies, and other stuff. There are certain strength properties that you want to look for that do what you. Also, each epoxy has other properties, some are more runny or thicker, and each fill its own place.

Devcon(all the metallic based epoxies), ProBed 2k, Marine Tex Grey, and AcraGlass are the most popular ones out there. I have heard some use industrial boiler epoxies, and other stuff. There are certain strength properties that you want to look for that do what you. Also, each epoxy has other properties, some are more runny or thicker, and each fill its own place.

Re: Bedding compounds

When bedding a base is it necessary to scuff the underside of the base, or should it just get degreased and bedded?

When bedding a base is it necessary to scuff the underside of the base, or should it just get degreased and bedded?

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jacko Jeebus</div><div class="ubbcode-body">When bedding a base is it necessary to scuff the underside of the base, or should it just get degreased and bedded? </div></div>

I've used Brownells Steel Bed for bedding bases for some time. I've found it best to knock off the finish on the underside of the base then degrease / clean it thoroughly. That way you will be sure to have the best adhesion.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jacko Jeebus</div><div class="ubbcode-body">When bedding a base is it necessary to scuff the underside of the base, or should it just get degreased and bedded? </div></div>

I've used Brownells Steel Bed for bedding bases for some time. I've found it best to knock off the finish on the underside of the base then degrease / clean it thoroughly. That way you will be sure to have the best adhesion.

Re: Bedding compounds

I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close.

I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Lofty</div><div class="ubbcode-body">I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close. </div></div>

Which Devcon product did you buy from Midway?

The Devcon 10110 looks and acts nothing like the JB Weld that I own.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Lofty</div><div class="ubbcode-body">I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close. </div></div>

Which Devcon product did you buy from Midway?

The Devcon 10110 looks and acts nothing like the JB Weld that I own.

Re: Bedding compounds

Sounds like the majority prefer devcon with marinetex in second. Has anyone ever tried acraglass?

Sounds like the majority prefer devcon with marinetex in second. Has anyone ever tried acraglass?

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Dr. Vette</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Lofty</div><div class="ubbcode-body">I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close. </div></div>

Which Devcon product did you buy from Midway?

The Devcon 10110 looks and acts nothing like the JB Weld that I own. </div></div>

I got the 10110.

6.5 hours later and I can't tell the difference. Poking them both with the tip of an exacto, they fell identical.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Dr. Vette</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Lofty</div><div class="ubbcode-body">I just picked up some Devcon from Midway for my upcoming bedding project.

I mixed a small batch up just to test curing time. I noticed it smelled just like JB Weld. So I mixed together the same size batch of JB Weld less than 3 minutes later.

In equal portions, they were the same color, consistency and 4 hours later they are the same firmness. I put each batch inside plastic bottle caps and neither has expanded or shrunk.

Seems to be the exact same product, or at least very very close. </div></div>

Which Devcon product did you buy from Midway?

The Devcon 10110 looks and acts nothing like the JB Weld that I own. </div></div>

I got the 10110.

6.5 hours later and I can't tell the difference. Poking them both with the tip of an exacto, they fell identical.

Re: Bedding compounds

There are a couple flavors of JB Weld just like the Devcon... Or any other epoxy.

The display at my local hardware store has like 5 different formulas.

Like this topic, I'm planning on re-bedding a hunting rifle in the next couple weeks.

Dave

There are a couple flavors of JB Weld just like the Devcon... Or any other epoxy.

The display at my local hardware store has like 5 different formulas.

Like this topic, I'm planning on re-bedding a hunting rifle in the next couple weeks.

Dave

Re: Bedding compounds

Devcon here too. Bedded 3 rifles and based in the last year with a tub I got from Midway

Devcon here too. Bedded 3 rifles and based in the last year with a tub I got from Midway

Re: Bedding compounds

Devcon in the tubes that you get from midway is almost exactly the same as regular JB. I say almost, it was still neater and easier to release.

Devcon in the tubes that you get from midway is almost exactly the same as regular JB. I say almost, it was still neater and easier to release.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casey Simpson</div><div class="ubbcode-body">

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot. </div></div>Brain hurting....can't tell if serious....overload....OVERLOAD!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casey Simpson</div><div class="ubbcode-body">

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot. </div></div>Brain hurting....can't tell if serious....overload....OVERLOAD!

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: eracer</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casey Simpson</div><div class="ubbcode-body">

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot. </div></div>Brain hurting....can't tell if serious....overload....OVERLOAD! </div></div>

Haha I was scratching my head the other day about the butt down for the gun lube... figured I'd leave it alone.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: eracer</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casey Simpson</div><div class="ubbcode-body">

Use a quality, sticky, hard substance with bonding properties. Forego the use of any release agents.

All will be in one piece until the cows come home or the woods burn. Who needs to remove the steel from the stock anyway? Everyone knows triggers never get out of adjustment requiring work. And to displace unwanted water just wash it all out with WD-40 or Ronsonol.

Store the rig butt down if the stock is wood. Gun lube will bleed into the wood finish and turn it black but least it won't rot. </div></div>Brain hurting....can't tell if serious....overload....OVERLOAD! </div></div>

Haha I was scratching my head the other day about the butt down for the gun lube... figured I'd leave it alone.

Re: Bedding compounds

Devcon here. Painful though to lay out just under $60 for a 1# package.

For small jobs J-B Weld works fine. The "slow cure" is best. Doesn't have the structural strength of Devcon 10110 but great for scope bases.

Devcon here. Painful though to lay out just under $60 for a 1# package.

For small jobs J-B Weld works fine. The "slow cure" is best. Doesn't have the structural strength of Devcon 10110 but great for scope bases.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: werew</div><div class="ubbcode-body">+1 Devcon 10110</div></div>

yep this

if you watch Amazon you can catch it for $40

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: werew</div><div class="ubbcode-body">+1 Devcon 10110</div></div>

yep this

if you watch Amazon you can catch it for $40

Re: Bedding compounds

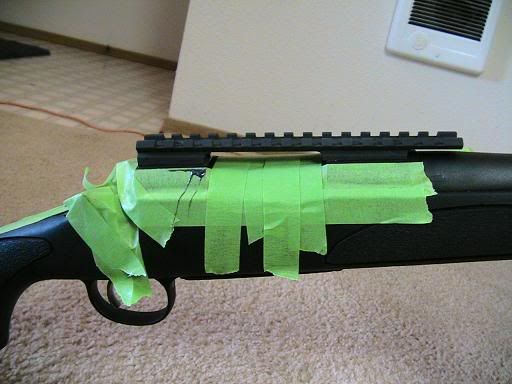

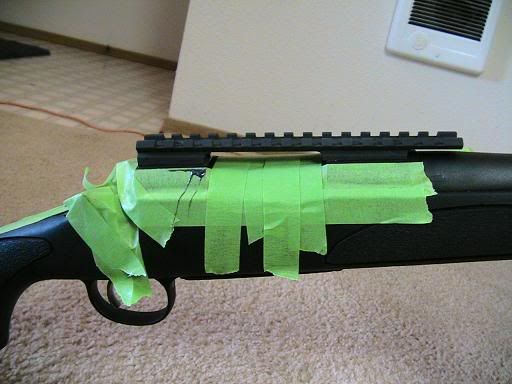

Just finished up my scope base project I was going to take pictures throughout but was so focused that I forgot. I used Devcon, turned out good I think. A little GM Cyber Gray touch up paint for the little nicks better than new. So I got a few after as follows.

Just finished up my scope base project I was going to take pictures throughout but was so focused that I forgot. I used Devcon, turned out good I think. A little GM Cyber Gray touch up paint for the little nicks better than new. So I got a few after as follows.

Re: Bedding compounds

I used steel bed a couple times and had good success with it. Its a bit pricey, so for the next projects, I am going to look at devcon or marine tex instead.

I used steel bed a couple times and had good success with it. Its a bit pricey, so for the next projects, I am going to look at devcon or marine tex instead.

Re: Bedding compounds

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: desertrat1979</div><div class="ubbcode-body">Devcon in the tubes that you get from midway is almost exactly the same as regular JB. I say almost, it was still neater and easier to release. </div></div>

Was not familiar with 10110 being available in tubes, only the larger containers. I dont think it is 10110 because the tubes are a 50/50 mix. I thought devcon was devcon until I did a bedding job with the hardware store version in a tube. When you go to cut or mill it away there is a vast difference in the way it cuts, much more brittle than 10110.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: desertrat1979</div><div class="ubbcode-body">Devcon in the tubes that you get from midway is almost exactly the same as regular JB. I say almost, it was still neater and easier to release. </div></div>

Was not familiar with 10110 being available in tubes, only the larger containers. I dont think it is 10110 because the tubes are a 50/50 mix. I thought devcon was devcon until I did a bedding job with the hardware store version in a tube. When you go to cut or mill it away there is a vast difference in the way it cuts, much more brittle than 10110.

Similar threads

- Replies

- 33

- Views

- 2K