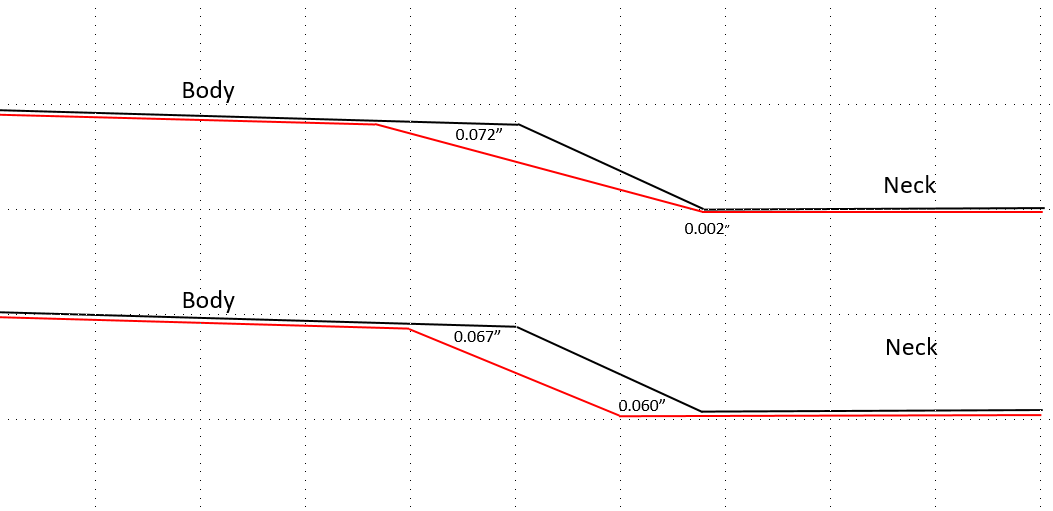

Ok. Fireforming to do the top one, the triangle void, is basically P.O.Ackley's method, or commonly "ackley improved". It works "easiest". You often find that Ackley imp reamers are 4thou (0.004" / 0.1mm) SHORTER, so when you close the bolt on a "normal" piece of brass in an ackley chamber, its a little stiff to close. This is normal on first firings.

If you do the second version, the trapizoidal, you have 2 options. False shoulder, or hard jam in lands.

If you try to fire a case like this, say a 6br in a 6brx chamber, or 6bra in a 6 dasher chamber, you often get a hang fire. The firing pin pushes the entire case forward in the chamber, and it doesn't reliably ignite. I have personally had case head seperations from this.

False shoulder is using a neck expander mandrel, say 30cal in your case because you wanted 7mm, then run through a sizing die to bring the neck back to 7mm, but NOT the whole neck, only like 3/4 of it, so you get a step, or "false shoulder".

This false shoulder allows the firing pin to hit without ramming the case into the chamber, and will fireform it properly.

Another option is to use a tight undersize bushing when you size the brass, and have the projectile jam 0.010" (10 thou) or so into the lands. Again, slightly stiff to close the bolt. This allows the firing pin to hit the primer properly without sending the case forward. It will fireform and blow out.

This is the most common way of doing it, because its the easiest and quickest for most people.

Does this answer your quesrion ?