Hey all,

I’ve never reloaded and am looking to see what I can do in working up a load for my 7PRC. I’ve done a fair bit of reading but would really appreciate input from those with firsthand experience, especially loading for the Berger 195s.

Right now I’ve got:

Reloading Plan

Here’s the process I’m planning to follow:

I’d also be open to the Berger 180s if they prove easier to tune, but I like the idea of running the heavier 195s in this caliber for the extra BC.

Powder Options

I’ve been looking at:

Dies

Haven’t bought dies yet. Do I need to jump into high-end dies to get .5 MOA or better, or will I be just fine with solid full-length sizing dies? Trying to keep it simple but not cut corners if it matters for consistency.

Primers

My plan was to run whatever large rifle magnum primers I can find are. Not sure if there’s stuff to watch out for from different brands, but figured there’s not much variation there just making sure I can ignite the powder.

Open to Suggestions

Totally open to any advice, this is my first time reloading. My buddy is helping me get set up, so I’m more focused on learning a repeatable, consistent process than squeezing out every last FPS. If you’ve got tips for brass prep, pressure signs to watch for in 7 PRC, or seating depth tricks, I’m all ears.

Thanks in advance for any guidance, excited to start tuning and see what this rifle can do!

I’ve never reloaded and am looking to see what I can do in working up a load for my 7PRC. I’ve done a fair bit of reading but would really appreciate input from those with firsthand experience, especially loading for the Berger 195s.

Right now I’ve got:

- ~60 rounds of factory 175 ELD-X left (pre powder change so getting 2,915 out my 22” barrel)

- ~160 pieces of once-fired Hornady brass

- Access to a buddy’s press and reloading gear

Reloading Plan

Here’s the process I’m planning to follow:

- Deprime and clean the brass

- Use a dummy round and comparator to find the lands, then back off 0.010-0.020” for initial seating

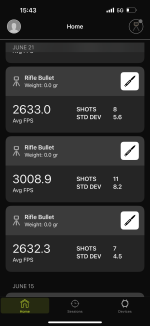

- Run a powder charge workup to find a velocity node for best SD/ES across similar charges

- Once I find a charge that looks good, I’ll fine-tune seating depth for accuracy

I’d also be open to the Berger 180s if they prove easier to tune, but I like the idea of running the heavier 195s in this caliber for the extra BC.

Powder Options

I’ve been looking at:

- H1000

- N560

- N565

- N570

- N565/N570 offer higher velocities due to the size of the powder and case capacity, but might be more temperature sensitive and tougher on barrels

- H1000 seems to be more temp stable and forgiving, even if slightly slower

Dies

Haven’t bought dies yet. Do I need to jump into high-end dies to get .5 MOA or better, or will I be just fine with solid full-length sizing dies? Trying to keep it simple but not cut corners if it matters for consistency.

Primers

My plan was to run whatever large rifle magnum primers I can find are. Not sure if there’s stuff to watch out for from different brands, but figured there’s not much variation there just making sure I can ignite the powder.

Open to Suggestions

Totally open to any advice, this is my first time reloading. My buddy is helping me get set up, so I’m more focused on learning a repeatable, consistent process than squeezing out every last FPS. If you’ve got tips for brass prep, pressure signs to watch for in 7 PRC, or seating depth tricks, I’m all ears.

Thanks in advance for any guidance, excited to start tuning and see what this rifle can do!