So Im shooting a factory Tikka T3x 300 win mag. 78g Retumbo 200g eldx. Ive been full length sizing my Hornady brass every reload. Its the only die I have for now. Brass only lasts 3 reloads before case head separation. Should a go away from full length sizing and just neck size and see if i get more brass life? i need some skilled advice here.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

brass life

- Thread starter WYCFM1

- Start date

Head separations are not caused by full length sizing, they’re caused by oversizing. We need more information. How much are you bumping your shoulders back during each sizing operation? How did you come to that dimension? How are you measuring headspace?So Im shooting a factory Tikka T3x 300 win mag. 78g Retumbo 200g eldx. Ive been full length sizing my Hornady brass every reload. Its the only die I have for now. Brass only lasts 3 reloads before case head separation. Should a go away from full length sizing and just neck size and see if i get more brass life? i need some skilled advice here.

Im not sure how much i was bumping shoulders back. i basically full length sized after shooting, trimmed, tumbled, primed, loaded, fired, i havent even gotten into the headspacing stuff yetHead separations are not caused by full length sizing, they’re caused by oversizing. We need more information. How much are you bumping your shoulders back during each sizing operation? How did you come to that dimension? How are you measuring headspace?

Getting in to the headspacing stuff should have been your first order of business.Im not sure how much i was bumping shoulders back. i basically full length sized after shooting, trimmed, tumbled, primed, loaded, fired, i havent even gotten into the headspacing stuff yet

Youre oversizing your cases.

Im not sure how much i was bumping shoulders back. i basically full length sized after shooting, trimmed, tumbled, primed, loaded, fired, i havent even gotten into the headspacing stuff yet

Lol yea without measuring your bump you are guaranteed to be way oversizing the brass especially on a belted mag

Your die is screwed in too far.

You should really invest in a headspace comparator so you can measure this.

Edit: back in the day when I first started and had no tools I would undersize a piece of brass then try and chamber it, then keep screwing the die down until the bolt closes with no resistance.

You should really invest in a headspace comparator so you can measure this.

Edit: back in the day when I first started and had no tools I would undersize a piece of brass then try and chamber it, then keep screwing the die down until the bolt closes with no resistance.

That’s kinda what I was thinking of doing but I was given loose mouth advice locally so I’ll start this tonightYour die is screwed in too far.

You should really invest in a headspace comparator so you can measure this.

Edit: back in the day when I first started and had no tools I would undersize a piece of brass then try and chamber it, then keep screwing the die down until the bolt closes with no resistance.

Ok so what I’m I looking for when using a head space comparator? Or how do I use it?Getting in to the headspacing stuff should have been your first order of business.

Youre oversizing your cases.

Ok so what I’m I looking for when using a head space comparator? Or how do I use it?

The comparator is just a datum, aka a hole that when the brass cases angled shoulder is inserted will always settle into the same location on the shoulder each time, which enables you to measure the exact same plane and its difference from the base of the case exactly. This lets you know how much you are shortening the case exactly.

That’s one measurement, probably the most important, but I also get the neck, shoulder and base diameters. For each step of my processing. It lets you see what’s actually happening and where.

So I’m sizing my brass from 1.455 on the shoulder to 1.4535 so I’m going .0015” of an inch. Between .001-.002 is generally good enough but the vid above goes into how an extra thou could be your preference.

The main thing is that you are sizing it down minimally to create just enough clearance for smooth consistent operation. It’s not screwing the die all the way down to size it as much as possible for .010 of brass movement, that’s over working it and will inevitably lead to premature failure.

Last edited:

I agree, you are oversizing your brass. I have a few different tools for measuring headspace and they are nice. But I learned how to reload long before everyone thought that you had to have a tool that measures in .0001.

Using a case fired in your rifle. Back your die out where there is a space between the mouth of the die. Maybe a 1/16 or even 1/32nd of an inch. Lube your case and run it all the way into the die. Then look at the case neck. You will see the line where the sizing stopped. Adjust the die down until you see that line meet the shoulder. Turn it down about 1/8th of a turn and lock it down. You can experiment with how far to turn the die down after that line meets the shoulder. Not enough will eventually make it hard to close the bolt. Too much will cause the problem you are having.

I learned this trick years ago from a gun writer named John Wooters.

Using a case fired in your rifle. Back your die out where there is a space between the mouth of the die. Maybe a 1/16 or even 1/32nd of an inch. Lube your case and run it all the way into the die. Then look at the case neck. You will see the line where the sizing stopped. Adjust the die down until you see that line meet the shoulder. Turn it down about 1/8th of a turn and lock it down. You can experiment with how far to turn the die down after that line meets the shoulder. Not enough will eventually make it hard to close the bolt. Too much will cause the problem you are having.

I learned this trick years ago from a gun writer named John Wooters.

Im not sure how much i was bumping shoulders back. i basically full length sized after shooting, trimmed, tumbled, primed, loaded, fired, i havent even gotten into the headspacing stuff yet

So...you are trimming every reload session? What is the length of the brass after firing and sizing? What is your trim length? Asking to see how much brass you are losing.

Three things to watch for if you want long brass life.

1-minimizing stretch on initial firing, lots of factory chambers are long and factory ammo is short.

If your chamber Is long I’d do a false shoulder on the first firing on brass you want to last.

I shoot for .003 or less initial case stretch.

2-minimizing stretch after resizing, maybe push the shoulder back .003 for hunting loads, .001-.002 is plenty in the majority of situations.

3-anneal before the necks and shoulders get rock hard. .

Thankfully headspace tools are fairly cheap.

I recently retired 250 260 Remington cases, my first head separation was on the 42nd firing.

Be nice to your brass and it will be nice to you.

1-minimizing stretch on initial firing, lots of factory chambers are long and factory ammo is short.

If your chamber Is long I’d do a false shoulder on the first firing on brass you want to last.

I shoot for .003 or less initial case stretch.

2-minimizing stretch after resizing, maybe push the shoulder back .003 for hunting loads, .001-.002 is plenty in the majority of situations.

3-anneal before the necks and shoulders get rock hard. .

Thankfully headspace tools are fairly cheap.

I recently retired 250 260 Remington cases, my first head separation was on the 42nd firing.

Be nice to your brass and it will be nice to you.

This will save you money and heartache.

www.midwayusa.com

www.midwayusa.com

Hornady Lock-N-Load Headspace Ga 5 Bushing Set Comparator

The Hornady Lock-N-Load Headspace Gauge is a great tool for increasing the accuracy of your loaded ammunition. The Headspace gauge measures from the...

Did not measure. As long as the bolt closed I wasn’t measuring. Especially when it shoots good tooSo...you are trimming every reload session? What is the length of the brass after firing and sizing? What is your trim length? Asking to see how much brass you are losing.

That’s insane.Three things to watch for if you want long brass life.

1-minimizing stretch on initial firing, lots of factory chambers are long and factory ammo is short.

If your chamber Is long I’d do a false shoulder on the first firing on brass you want to last.

I shoot for .003 or less initial case stretch.

2-minimizing stretch after resizing, maybe push the shoulder back .003 for hunting loads, .001-.002 is plenty in the majority of situations.

3-anneal before the necks and shoulders get rock hard. .

Thankfully headspace tools are fairly cheap.

I recently retired 250 260 Remington cases, my first head separation was on the 42nd firing.

Be nice to your brass and it will be nice to you.

ok guys so i bought the hornday headspace gauge for my win mag and started with fresh factory brass. i fire formed a bunch of brass and measured a few different pieces throughout. my fire form brass was growing .012 on average. some grew up to .017!!! i think my chamber headspace needs shortened because after FL sizing my once fired brass and bumping the shoulder back .002 i still only got 3-4 reloads out of my brass only needing to trim once. i just shot today and had 5 cases that were showing that crack right above the belt. have my gunsmith fix chamber headspace to reduce the initial fire form gain?

iam currenlty shooting 78.5 gn retumbo fed215 berger 180g elite hunter, and it shoots really nice.

iam currenlty shooting 78.5 gn retumbo fed215 berger 180g elite hunter, and it shoots really nice.

Your gunsmith, unless he’s a ninja, will not be able to help because the 300WM headspaces on the belt. You tell him the headspace too big and he’ll check and tell you it’s within spec. You need someone to turn the barrel back and recut the belt recess without the use of a chambering reamer. The problem then is you’ll have a nice chamber that won’t stretch brass BUT your chamber volume will be a lot smaller and you’ll have to use lower powder charges. You will have to be careful with reloading data.

Do you suppose this could be a big part of why I can’t get decent brass life? I use a Hornady match grade FL and plenty of case lube, if that gives some insight. Or what do you suggest?Your gunsmith, unless he’s a ninja, will not be able to help because the 300WM headspaces on the belt. You tell him the headspace too big and he’ll check and tell you it’s within spec. You need someone to turn the barrel back and recut the belt recess without the use of a chambering reamer. The problem then is you’ll have a nice chamber that won’t stretch brass BUT your chamber volume will be a lot smaller and you’ll have to use lower powder charges. You will have to be careful with reloading data.

Is it why? No, but its certainly part.

Try jamming the bullet into the lands. That will help keep the case head pressed up tight against the bolt face before it seals off and limit stretching at the web. The reasoning being if its already back then the shoulder will just form to the new location at that end of the case. When its not tight back against the bolt face the neck will swell up and seal off the chamber and then the case head will stretch back until it hits the bolt face stretching the body down at the web.

You can do something similar in that you expand the neck and then resize it back down partially. The larger unsized part down will jam up in the chamber neck and serve as that backward pressure/stretch limiting measure.

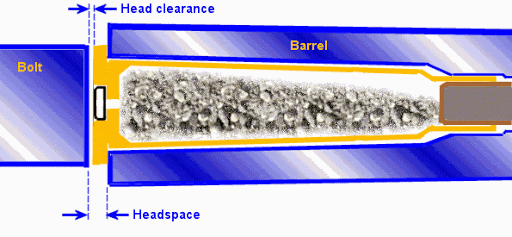

This is for a rimmed cartridge instead of a belted but it illustrates the point, the gap cause because the case has extra space around it. When it fills that gap it stretches.

Or you could try different brass and hope it does better.

Try jamming the bullet into the lands. That will help keep the case head pressed up tight against the bolt face before it seals off and limit stretching at the web. The reasoning being if its already back then the shoulder will just form to the new location at that end of the case. When its not tight back against the bolt face the neck will swell up and seal off the chamber and then the case head will stretch back until it hits the bolt face stretching the body down at the web.

You can do something similar in that you expand the neck and then resize it back down partially. The larger unsized part down will jam up in the chamber neck and serve as that backward pressure/stretch limiting measure.

This is for a rimmed cartridge instead of a belted but it illustrates the point, the gap cause because the case has extra space around it. When it fills that gap it stretches.

Or you could try different brass and hope it does better.

Both of those techniques will help.Is it why? No, but its certainly part.

Try jamming the bullet into the lands. That will help keep the case head pressed up tight against the bolt face before it seals off and limit stretching at the web. The reasoning being if its already back then the shoulder will just form to the new location at that end of the case. When its not tight back against the bolt face the neck will swell up and seal off the chamber and then the case head will stretch back until it hits the bolt face stretching the body down at the web.

You can do something similar in that you expand the neck and then resize it back down partially. The larger unsized part down will jam up in the chamber neck and serve as that backward pressure/stretch limiting measure.

Or you could try different brass and hope it does better.

Even if your resizing minimally a large stretch on first firing will do the damage and hurt brass life.

Just do a run of once firing the brass.Sorry guys no can do on jamming lands. It’s a hunting rifle and needs to feed in 3.715 aics mag.

After that resize normally.

Jamming the bullets is just a fire forming method. You may need to reduce powder charge for this also. Jamming will cause a pressure spike. After you have your brass formed, you still might neck size for another firing as the shoulders continue to move forward. .017 is a long ways, but its not really abnormal. The "headspace" in my Criterion 300wm barrel is at least .012 longer than the shoulder of the virgin brass I started with. Here is a belted mag headspace gauge.

Would anybody here consider 78.5gn of retumbo and a 180gr bullet out of factory 24” barrel a hot load? I don’t want to change because this consistently shoots .625” at 100m

On which brass? In Hornady brass...sounds a lot like my 230gr A-Tip load....in ADG brass....I'll refrain from comment. What are your speeds? What does your brass look like? What does your recoil impulse feel like?

Do you suppose this could be a big part of why I can’t get decent brass life? I use a Hornady match grade FL and plenty of case lube, if that gives some insight. Or what do you suggest?

What causes brass stretching is too much shoulder bump and too much pressure. Jaming won’t help because the belt already controls the forward movement of the case. Plus the strike of the firing pin will easily overcome the bullet in the rifling and will simply jam it deeper.

You can always make 300WM brass from 300H&H brass by forming a shoulder at the appropriate height and cutting off the excess neck length.

Or you can fireform new 300WM brass using a low pressure load with something like Trailboss. 22.something of TB under a 150gr bullet is a real nice plinking load, does 1700 FPS and has the same poi at 100 yards as a full power load.

That way you will get only some of the case stretch and good brass life after provided you only bump .002”

Recoil feels like they are going pretty good. But I wouldn’t say over 3000 FPS. It feels like the recoil is really fast. Also I run a hellfire brake soOn which brass? In Hornady brass...sounds a lot like my 230gr A-Tip load....in ADG brass....I'll refrain from comment. What are your speeds? What does your brass look like? What does your recoil impulse feel like?

Similar threads

- Replies

- 10

- Views

- 519

- Replies

- 41

- Views

- 1K

- Replies

- 5

- Views

- 335