Re: Brass resizing

The real trick to trimming is to not do it, AND to not have to do it.

When I was a knuckle dragging reloader that smacked the shell holder into the bottom of a full length sizer die, I DESERVED to waste my time trimming brass.

One or two firings and sizings and the brass grew so long that the load book says it is time to trim.

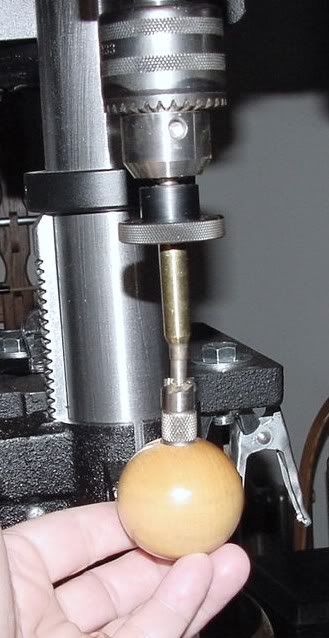

Then I learned I could get better groups at the range if I partial neck sized with a full length die. That is by adjusting the die to be far away from the shell holder when the press ram is up.

Then I learned I could adjust a FL die to only push back the shoulder .001".

The Lee Collet neck dies were gathering dust on my shelf because they looked cheap next to my Redding dies.

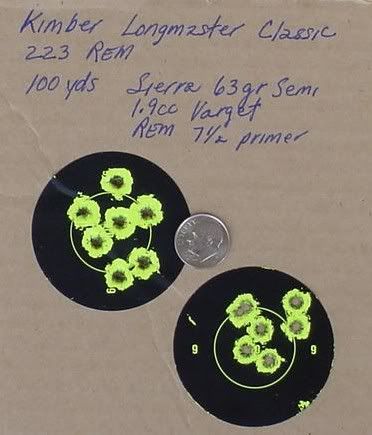

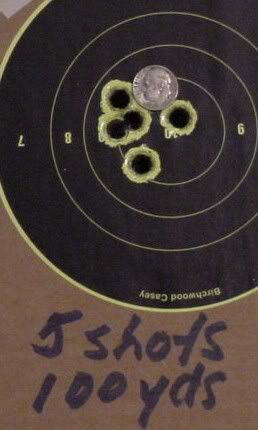

Then I learned that the Lee Collet neck dies make better ammo than my Redding S dies, despite the cheap look.

With the Lee Collet neck dies, I could get 25 firings between trimming.

Then I learned that the max case length in the book is not as accurate as I could measure and calculate for a gun and some ammo. The chamber neck length, minus how far the case will be pushed by the firing pin, is the REAL max case length. How long the case can be then is partially a function of how far I pushed the shoulder back. If the FL die pushes the shoulder back, then the firing pin can push the case forward in the chamber that same amount. When the case goes forward, the case mouth might reach the end of the chamber neck and swage down into the bullet. That would cause a deformed and inaccurate bullet AND a big pressure spike.