Took a precision course a few years ago and at one point during the shoot, the instructor grabbed my rifle, said "you don't need this on there", took a pair of pliers to the rear swivel and snapped it off in what I'm guessing was an attempt to unscrew it. Needless to say I was PISSED but I kept my cool out of respect for my shooting partner who I hadn't seen in several years. We'd arranged this course together as a "bro-up" reunion of sorts months prior and I didn't want to ruin it for him. He'd gotten out of the military circle years beforehand and the shoot meant a lot to him.

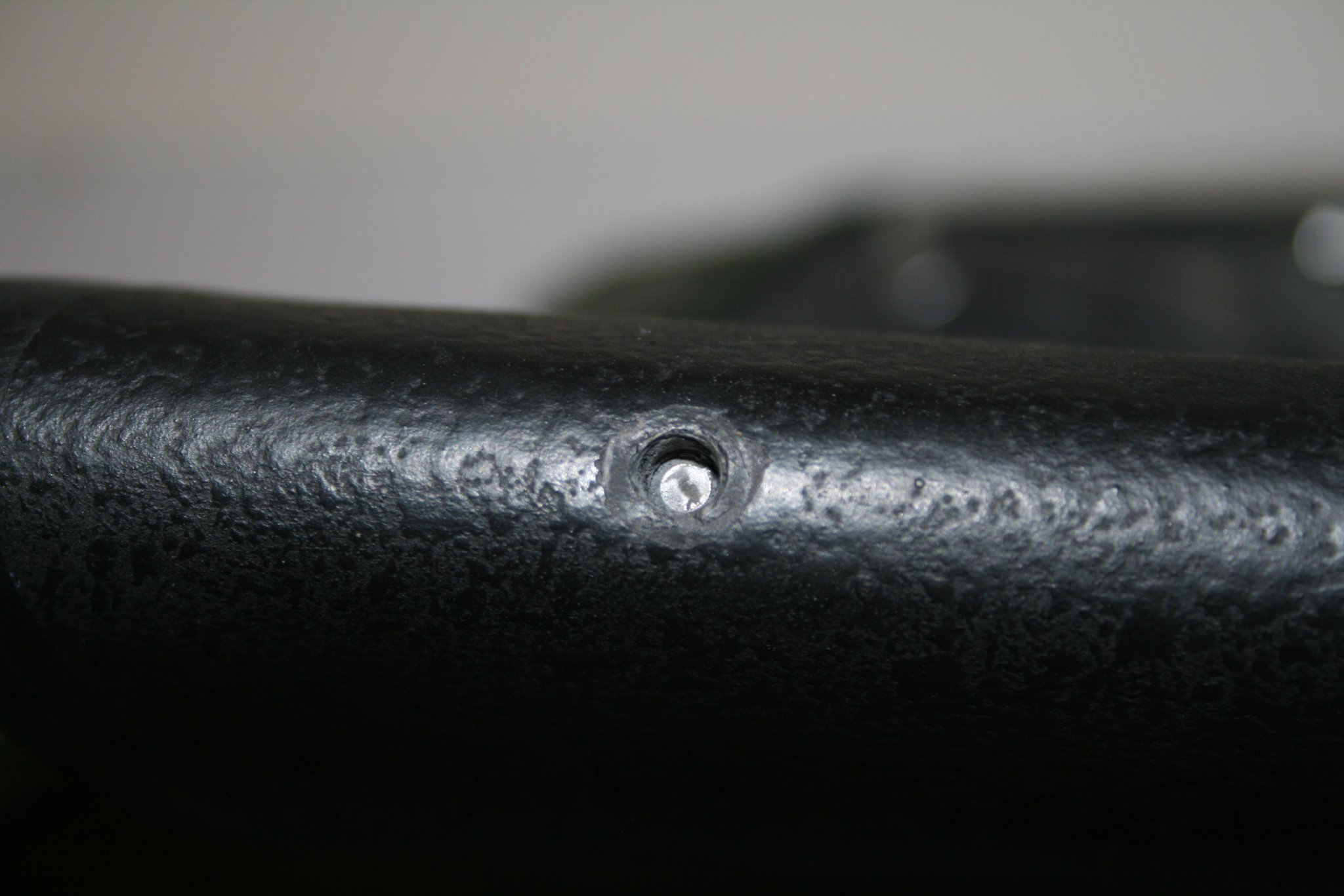

Anyhoo- Chandler system(I know..."ouch") on a McMillian stock. Here's pics of the rifle and the damage. Rear sling swivel broke off:

What's the recommended course of action, call McMillan, new stock, or can someone recommend somebody who can do this? I'd like it fixed,

Anyhoo- Chandler system(I know..."ouch") on a McMillian stock. Here's pics of the rifle and the damage. Rear sling swivel broke off:

What's the recommended course of action, call McMillan, new stock, or can someone recommend somebody who can do this? I'd like it fixed,