we call that buying factory loadedI

I’m in a phase of do as little as possible.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bushing or mandrel or both?

- Thread starter Islas82

- Start date

Reopening this thread. I have the Sac Gt die with .266 bushing. Picked up the .241 decapping mandrel and did some testing. I found no difference with or without the mandrel. I think if you are using a smaller diameter bushing and then opening the neck it may make some difference but at my combo of .266 and .241 it was doing little to nothing.

When you say "picked up a .241 decapping mandrel..." it sounds like you mean that you're using SAC's "Decapping Expander Mandrel" part that goes inside the SAC dies... or are you using a separate, standalone mandrel in a mandrel die that you're doing in a second step?

I ask because the two are far from the same... every modified expander ball decapping stem design that I've ever seen (including SAC's and A419's) is more of a "pseudo-mandrel" in name only.

If you think about it, any sizing die with a true/legit mandrel inside it wouldn't work... because if it did what it's supposed to do and what a separate mandrel step does, every f'ing case would get stuck because there wouldn't be enough room for the case's wall thickness lol.

I'm all for doing as little as possible too, but I still hit a mandrel in a separate step because IMHO it's worth it.

Pass on Hornady.we call that buying factory loaded

Yes the decapping mandrel they sell. In my situation it wasn’t doing much. .241 mandrel and .266 bushing combination allowed the mandrel to just slip in and out. I have a 21st century mandrel die with their 6mm turning arbor. So I’ve used both.When you say "picked up a .241 decapping mandrel..." it sounds like you mean that you're using SAC's "Decapping Expander Mandrel" part that goes inside the SAC dies... or are you using a separate, standalone mandrel in a mandrel die that you're doing in a second step?

I ask because the two are far from the same... every modified expander ball decapping stem design that I've ever seen (including SAC's and A419's) is more of a "pseudo-mandrel" in name only.

If you think about it, any sizing die with a true/legit mandrel inside it wouldn't work... because if it did what it's supposed to do and what a separate mandrel step does, every f'ing case would get stuck because there wouldn't be enough room for the case's wall thickness lol.

I'm all for doing as little as possible too, but I still hit a mandrel in a separate step because IMHO it's worth it.

Even with just sizing using the .266 bushing and then running it under my 21st century mandrel the mandrel just slips in and out of the case mouth.

If I or someone was using a bushing smaller than .266 I could see the mandrel actually opening the case mouth up but in my situation .266 is already larger and the mandrel doesn’t actually do anything.

I’ve read GAP recommends starting with a .266 bushing so that’s what I got. Works well and I get great numbers without a mandrel.

I dont care what others are doing. If I’m getting SD of 6 or less on a 10 round string with what I’m doing. It works.

Last edited:

You haven’t actually looked at how the sac mandrel works, have you?If you think about it, any sizing die with a true/legit mandrel inside it wouldn't work... because if it did what it's supposed to do and what a separate mandrel step does, every f'ing case would get stuck because there wouldn't be enough room for the case's wall thickness lol.

Last edited:

You haven’t actually looked at how the sac mandrel works, have you?

View attachment 8715192

Yep. I’ve seen it. Not a mandrel.

Explain.Yep. I’ve seen it. Not a mandrel.

Just the compression vs tension via direction that they travel? Or do you have a new definition of what a mandrel is?

Pass on Hornady.

Yes the decapping mandrel they sell. In my situation it wasn’t doing much. .241 mandrel and .266 bushing combination allowed the mandrel to just slip in and out. I have a 21st century mandrel die with their 6mm turning arbor. So I’ve used both.

Even with just sizing using the .266 bushing and then running it under my 21st century mandrel the mandrel just slips in and out of the case mouth.

If I or someone was using a bushing smaller than .266 I could see the mandrel actually opening the case mouth up but in my situation .266 is already larger and the mandrel doesn’t actually do anything.

I’ve read GAP recommends starting with a .266 bushing so that’s what I got. Works well and I get great numbers without a mandrel.

I dont care what others are doing. If I’m getting SD of 6 or less on a 10 round string with what I’m doing. It works.

If you’re getting SDs ~6 and you’re happy with your ammo then there might not me much to gain.

That said, you could maybe try a tighter bushing before hitting the separate mandrel and see what you get?

I used a .268” and .267” bushings for a long time and they didn’t seem to shrink the case mouths enough for my .241” mandrel to get much engagement or really do much.

I switched to a regular Hornady/GAP die that is supposedly honed to .266” (but actually sizes a smidge smaller than that in practice) and immediately got more feel/engagement and it brought my stuff up a notch for sure.

If one looks at how SAC’s Decapping Expander Mandrel works inside their dies, one can see that first it expands the case mouth (not doing a whole lot on the way in as the case mouth is open with fired brass), then there’s a smaller OD section on the “mandrel” that allows the die body to squeeze down the case neck/mouth without the brass getting stuck inside the die, and then it pulls the fatter OD “mandrel” section out of the case (like a traditional expander ball would work, and arguably this is the only time their “mandrel” is really sizing anything). It’s a really good, updated, expander-ball design, but it’s not a mandrel and doesn’t work the same way a traditional mandrel in a second step does.

Half of the point of using a mandrel is to not have to pull up against the case’s shoulder while sizing the neck like a traditional expander-ball piece would… but that’s exactly how the SAC piece works.

What were your numbers before and after the switch?If you’re getting SDs ~6 and you’re happy with your ammo then there might not me much to gain.

That said, you could maybe try a tighter bushing before hitting the separate mandrel and see what you get?

I used a .268” and .267” bushings for a long time and they didn’t seem to shrink the case mouths enough for my .241” mandrel to get much engagement or really do much.

I switched to a regular Hornady/GAP die that is supposedly honed to .266” (but actually sizes a smidge smaller than that in practice) and immediately got more feel/engagement and it brought my stuff up a notch for sure.

If one looks at how SAC’s Decapping Expander Mandrel works inside their dies, one can see that first it expands the case mouth (not doing a whole lot on the way in as the case mouth is open with fired brass), then there’s a smaller OD section on the “mandrel” that allows the die body to squeeze down the case neck/mouth without the brass getting stuck inside the die, and then it pulls the fatter OD “mandrel” section out of the case (like a traditional expander ball would work, and arguably this is the only time their “mandrel” is really sizing anything). It’s a really good, updated, expander-ball design, but it’s not a mandrel and doesn’t work the same way a traditional mandrel in a second step does.

Half of the point of using a mandrel is to not have to pull up against the case’s shoulder while sizing the neck like a traditional expander-ball piece would… but that’s exactly how the SAC piece works.

Explain.

Just the compression vs tension via direction that they travel? Or do you have a new definition of what a mandrel is?

See the post above.

On the way down into a case, a mandrel pushes the neck open with the strong mechanical advantage of the case's shoulder supporting it, which delivers the consistent sizing (same concept as why an arch can support a lot of weight in architecture due to the distribution of the forces working against it). On the way up/out, a mandrel isn't really doing much of anything.

Arguably, you get a more consistent neck and don't distort the case shoulder doing it this way.

With the SAC piece, it's just a fancy expander-ball design, that still pulls up on the shoulder while sizing the neck, and not sizing as consistently due to not being supported.

What were your numbers before and after the switch?

Before: my stuff came out really good most of the time and I had mostly single-digit SDs, but I could tell while seating bullets that my neck tension could be more consistent... Over 20 shots my SDs were usually in the 7-9 range.

After: my stuff comes out great every time, low single-digit SDs are the norm, and now seating bullets is a different and more satisfying experience as the neck tension of every case is now about as consistent as can be (and I can feel it at the handle). Now my stuff is always in the SD 4-6 range over 20 shots, but that doesn't tell the whole story, as the targets/plates routinely show me that my stuff has improved more than the numbers show (and if I miss it's me). I get a super consistent waterline downrange, on average, my vertical dispersion is only ~3" at 1000 yards since making the switch.

(FWIW those SD numbers are from me just blasting away with a Xero on top of the rifle off props and shit... if I sit down at a bench in the shade, and wait a minute between rounds like most fudds do, I've seen SDs in the 2-3 range over 20 shots.)

Doing the mandrel step won't turn one's crappy ammo into match ammo... but if one is already making good stuff, IME it can just make it so all your stuff comes out boringly, reliably great so you don't even have to think about it.

Don't get the wrong idea... I'm not looking to do any extra or unnecessary reloading steps. I don't even clean my brass before I size it, and I've never turned a single neck lol... but the mandrel step doesn't take long and isn't that annoying compared to a lot of the other reloading stuff we do, and from what I've seen it makes a difference for the better and works, so I do it.

Last edited:

What about the pma expander? It is a traditional expander like you describe, only it’s purposefully thin top and bottom.See the post above.

On the way down into a case, a mandrel pushes the neck open with the strong mechanical advantage of the case's shoulder supporting it, which delivers the consistent sizing (same concept as why an arch can support a lot of weight in architecture due to the distribution of the forces working against it). On the way up/out, a mandrel isn't really doing much of anything.

Arguably, you get a more consistent neck and don't distort the case shoulder doing it this way.

With the SAC piece, it's just a fancy expander-ball design, that still pulls up on the shoulder while sizing the neck, and not sizing as consistently due to not being supported.

Yeah the argument is the down stroke still does most of the interfacing with the brass but still.

Don’t get me wrong, I still use the traditional mandrel sets myself, purely due to economics and prior investment. It is still literally twice the handling steps in a non progressive presss than the combo dies.

I just think that if someone is using these ultra match grade combo dies that they probably aren’t using crappy enough brass for the differences in tensile strengths on the small sizing operations to have a measurable effect on outcome.

What about the pma expander? It is a traditional expander like you describe, only it’s purposefully thin top and bottom.

View attachment 8715300

Yeah the argument is the down stroke still does most of the interfacing with the brass but still.

Don’t get me wrong, I still use the traditional mandrel sets myself, purely due to economics and prior investment. It is still literally twice the handling steps in a non progressive presss than the combo dies.

I just think that if someone is using these ultra match grade combo dies that they probably aren’t using crappy enough brass for the differences in tensile strengths on the small sizing operations to have a measurable effect on outcome.

If someone could come up with an inside-the-die design that did the same exact thing as a separate mandrel step, I'd be all over it. I'm all for having fewer steps lol!

I'm not doing a separate mandrel step due to the economics of prior investment or any of that, I'm just doing it because it seems to work and my ammo comes out better that way and as far as I can tell two steps is what it takes. I'm all for buying as much performance as I can when I can lol.

IMHO, the problem is just good 'ol math: if one uses a .266" bushing, but also wants to use a traditional .241" mandrel inside a die at the same time, they're kind of fucked since the tolerance will only allow brass with a consistent case wall thickness of ~.0125" to not get stuck (.266 - .241 = 0.025 and I guess we'd divide that by 2?) ... so IDK if it's even possible to pull off sizing the outside of the cases and sizing the inside OD of the case necks both at the same time.

If one doesn't want to handle the brass an extra time, then the easiest way is probably just to use a progressive press... but the thing is, after experimenting, I accidentally figured out that it's better to wait until after brass comes out of the tumbler from tumbling off all the sizing lube to do the mandrel step (as the case mouths get more f'ed up then most would think with them crashing into each other in the tumbler). So, for me at least, two separate steps it is.

Last edited:

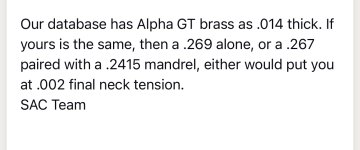

From SACIf someone could come up with an inside-the-die design that did the same exact thing as a separate mandrel step, I'd be all over it. I'm all for having fewer steps lol!

I'm not doing a separate mandrel step due to the economics of prior investment or any of that, I'm just doing it because it seems to work and my ammo comes out better that way and as far as I can tell two steps is what it takes. I'm all for buying as much performance as I can when I can lol.

IMHO, the problem is just good 'ol math: if one uses a .266" bushing, but also wants to use a traditional .241" mandrel inside a die at the same time, they're kind of fucked since the tolerance will only allow brass with a consistent case wall thickness of ~.0125" to not get stuck (.266 - .241 = 0.025 and I guess we'd divide that by 2?) ... so IDK if it's even possible to pull off sizing the outside of the cases and sizing the inside OD of the case necks both at the same time.

If one doesn't want to handle the brass an extra time, then the easiest way is probably just to use a progressive press... but the thing is, after experimenting, I accidentally figured out that it's better to wait until after brass comes out of the tumbler from tumbling off all the sizing lube to do the mandrel step (as the case mouths get more f'ed up then most would think with them crashing into each other in the tumbler). So, for me at least, two separate steps it is.

Attachments

For people wondering about the efficacy of using a mandrel - and I'm adding in neck lube along with it - please look at this overlay of seating forces for two different groups of bullets.

One of the groups was using neck lube plus a mandrel, while the other used neither. See if you can guess which is which. Oh, and this was Lapua brass for both, same prep aside from lube/mandrel, no neck turning. And before you ask, yes, seating force consistency has a correlation to SDs.

EDIT: Some of my earlier tests are in this thread. This is before I got my AMP Press and are smaller sample sizes. The first post has a comparison of no mandrel vs. using a mandrel. Sample size is smaller, but it shows a fairly significant difference.

www.snipershide.com

www.snipershide.com

One of the groups was using neck lube plus a mandrel, while the other used neither. See if you can guess which is which. Oh, and this was Lapua brass for both, same prep aside from lube/mandrel, no neck turning. And before you ask, yes, seating force consistency has a correlation to SDs.

EDIT: Some of my earlier tests are in this thread. This is before I got my AMP Press and are smaller sample sizes. The first post has a comparison of no mandrel vs. using a mandrel. Sample size is smaller, but it shows a fairly significant difference.

Mandrel Musings

When I first got my K&M arbor press for seating, I was somewhat surprised at the spread of the values of force required to seat bullets. Knowing that neck tension plays a significant role in ES/SD, I started doing various things to try to bring seating force in line. I had been doing most my...

I've been using a full length bushing die to size down, decapping done first using a universal decapper before tumbling. I then use a 0.241" carbide mandrel to open up and the seat with graphite in the necks, seems pretty consistent. I don't tumble after sizing as I am a low volume shooter so just wipe down with solvent. As CK alludes to, I'm looking at a slightly tighter bushing as the mandrel hardly feels like it is touching the neck.

For people wondering about the efficacy of using a mandrel - and I'm adding in neck lube along with it - please look at this overlay of seating forces for two different groups of bullets.

One of the groups was using neck lube plus a mandrel, while the other used neither. See if you can guess which is which. Oh, and this was Lapua brass for both, same prep aside from lube/mandrel, no neck turning. And before you ask, yes, seating force consistency has a correlation to SDs.

View attachment 8715447

EDIT: Some of my earlier tests are in this thread. This is before I got my AMP Press and are smaller sample sizes. The first post has a comparison of no mandrel vs. using a mandrel. Sample size is smaller, but it shows a fairly significant difference.

Mandrel Musings

When I first got my K&M arbor press for seating, I was somewhat surprised at the spread of the values of force required to seat bullets. Knowing that neck tension plays a significant role in ES/SD, I started doing various things to try to bring seating force in line. I had been doing most my...www.snipershide.com

Seating force does not correlate to sd.

I’ve shot plenty of f class matches with sd under 5-7 never touching a mandrel or neck lube

I still use a Lee Collet die when I can. Otherwise I use a Forster FL die, expander removed, followed by an expander mandrel.

I've been using a full length bushing die to size down, decapping done first using a universal decapper before tumbling. I then use a 0.241" carbide mandrel to open up and the seat with graphite in the necks, seems pretty consistent. I don't tumble after sizing as I am a low volume shooter so just wipe down with solvent. As CK alludes to, I'm looking at a slightly tighter bushing as the mandrel hardly feels like it is touching the neck.

This is in the same ballpark as my process, including wiping down cases vs. another tumble. I think it takes similar time to wipe down each case as it takes to deal with the tumbling media for each case - and you don't have to wait however long for the tumble.

Yes good point. I'm only loading roughly 50 rounds at a time. If I was loading hundreds of rounds, like the PRS boys, I'd be looking to automate as much as possible.This is in the same ballpark as my process, including wiping down cases vs. another tumble. I think it takes similar time to wipe down each case as it takes to deal with the tumbling media for each case - and you don't have to wait however long for the tumble.

I started looking at what the BR and F Class lot were doing and then whittling it down to a process to that gave most of the benefits. I don't need to be neck turning, or weighing every component. If I can hit a 1 MOA target at distance reliably factoring in the wind I'll be very happy.

I started looking at what the BR and F Class lot were doing and then whittling it down to a process to that gave most of the benefits. I don't need to be neck turning, or weighing every component. If I can hit a 1 MOA target at distance reliably factoring in the wind I'll be very happy.

Most F-class shooters are *very* happy if they can consistently hit a 1 moa target in the wind at distance... as that's the size of the 10-ring. A 200 with a low X count trumps a 199 with a high X count, every time

Yes wind is the real leveller. That's where my real gains are to be had.Most F-class shooters are *very* happy if they can consistently hit a 1 moa target in the wind at distance... as that's the size of the 10-ring. A 200 with a low X count trumps a 199 with a high X count, every time

Similar threads

- Replies

- 15

- Views

- 577

- Replies

- 8

- Views

- 549