I'm late to the party on this subject but some might find what follows interesting.

I'm only shooting 33XC at the moment, so that means Peterson brass only.

Sort cases by case weight or by H2O?

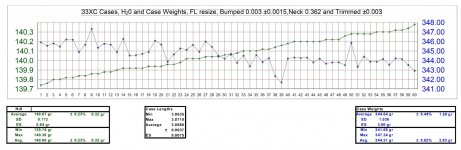

Jump to the chart comparing cases sorted by H2O weight [green] and its empty case weight [blue]. Note the wildly varying case weights. You might exclude 8 or 9 cases based on brass weight, but in terms of H2O, there would be no reason to.

There has been discussion about at what point to measure H2O.

I can see some logic in weighing H2O in fired brass, in that is what the brass expands to.

I don’t do that. I prepare my fired brass ready to reload, to be physically the same external measurements.

All brass for competitive or research use has been fired at least once and I AMP anneal after all cleaning processes, every time.

My fired brass have the neck walls FClass Products Auto IDOD turned to 0.013 ±0.0005 or better.

De-prime with a hand de-primer.

Primer pocket depth unify. (Cleans)

Flash hole debur (removed carbon from inside the flash hole)

Wet tumble clean with a Rebel 17.

Full length resize to bump -0.003 ±0.0015 and neck resize with 0.362 collar.

Cases dry rumbled for 10 - 20 minutes to remove all lubricant.

Neck trimmed (inner and outer chamfer) with Giraud Power Trimmer (not Tri-Way Trimmer)

Notes on two of the above processes.

The Bump process gives a length based on base to shoulder. ±0.0015 is as best I can achieve. I have tried two methods to combat spring back.

A single resize movement and hold for 4 seconds and a double resize movement, holding for two seconds. The latter seems more consistent in that a third movement does not always change the bump.

Then the Giraud Trimmer ID and OD chamfers the neck using the shoulder as the datum, BUT the cutter is a V, so whilst the inner and outer chamfers are consistent, the actual end rim is not trimmed. If it was, it would be a knife edge around the case rim.

This V trimming produces case lengths ± 0.0037. This is made of the Bump being ±0.0015 and the Giraud Trimmer case neck end being ±0.0015 (I know that adds up to ±0.003 but measuring 60 cases, the lengths were ±0.0037)

I’m debating on having two Giraud Trimmers, one with a flat blade, which would trim the neck length consistently based on the shoulder and therefor the case lengths would be ±0.0015 based solely on the Bump tolerance.

Why should this matter?

Well when it comes to measuring H2O, you see the water’s meniscus based on the end of the neck, which in turn affects the H2O weight. See photos.

Then weigh every case on an A&D FX-120i scale (±0.02gr)

Fit a fired primer with anvil still in place. I don’t put a primer in upside down. So fiddly I don’t have the patience.

Re-weigh the cases.

Fill with room temperature water, to an as constant meniscus as I can.

Re-weigh with water.

I empty out the water and dry air blast the case but leave the primer in.

All the figures are entered in a spreadsheet, then sorted by increasing H2O only weight.

I then look at the graphs.

Sometimes, there is an anomalous weight, which is why I leave the primers in, so I can re-weigh.

I throw out cases which are obviously anomalously light or heavy H2O (I use those as fowlers) and print the data and graphs.

If you look at my graphs (H2O green on the left, empty case weight blue on the right) you will see that as the H2O increases (the VOLUME), the weight of the empty cases decreases.

My only explanation is that the cases wall thicknesses decrease and/or the internal case head base decreases in thickness. Both would allow more volume.

My sorted cases have an average H2O weight of 140.07gr ± 0.32gr or ±0.23%

So what?

QuickLoad tells me that could vary the Mv 7fps before I start reloading. So I reload and shoot cases sequentially based on H2O and not shuffle the cases.

All the above is why I sort by H2O and not brass weight.