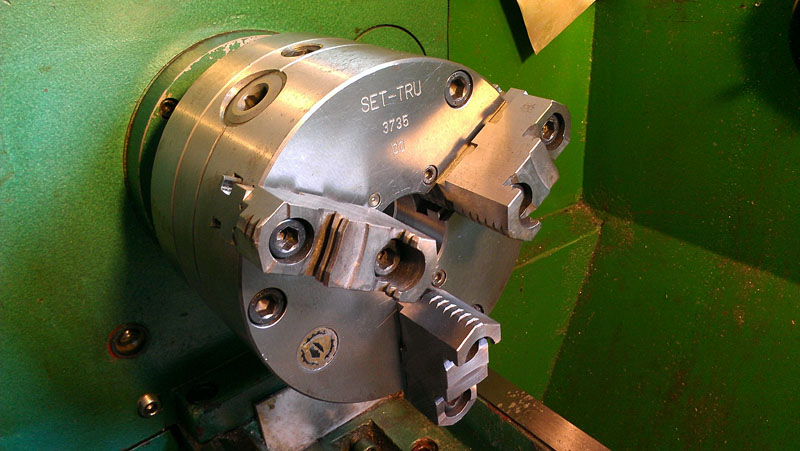

Want to get a new quality 4-jaw for my Clausing. Its a D1-4 mount, and I want it to be direct mount for length concerns. Seems theres only about two choices out there that Im finding, Gator or Bison. I know the Bison are good to go. Anyone have any experience with the Gators? They are about $200 cheaper, and if theyre the same quality that would be nice.

Second question is size, torn between 8 and 10". Id like the extra weight of the 10", and I dont mind lifting it up there. My hope would be that the extra weight would keep vibration down when a barrel is off center slightly. However, Im not sure if it would work against me since the larger jaws would be off center also, possibly causing vibration in itself.

Last, do you think the only way Im going to do any kind of machining on the jaws is with EDM? Im thinking a carbide end mill wont touch them, but maybe someone has tried?

Thanks

Second question is size, torn between 8 and 10". Id like the extra weight of the 10", and I dont mind lifting it up there. My hope would be that the extra weight would keep vibration down when a barrel is off center slightly. However, Im not sure if it would work against me since the larger jaws would be off center also, possibly causing vibration in itself.

Last, do you think the only way Im going to do any kind of machining on the jaws is with EDM? Im thinking a carbide end mill wont touch them, but maybe someone has tried?

Thanks

Last edited: