Hopefully I can explain this in a manner that is clear to everyone and hopefully someone knowledgeable is out there who knows what's up.

For ease of visualization, I'll talk about Unertl external adjusted type scopes (US Optics SN-9 included), however, the same principle is in effect (to my knowledge) on erector tubes inside a scopes main-tube housing.

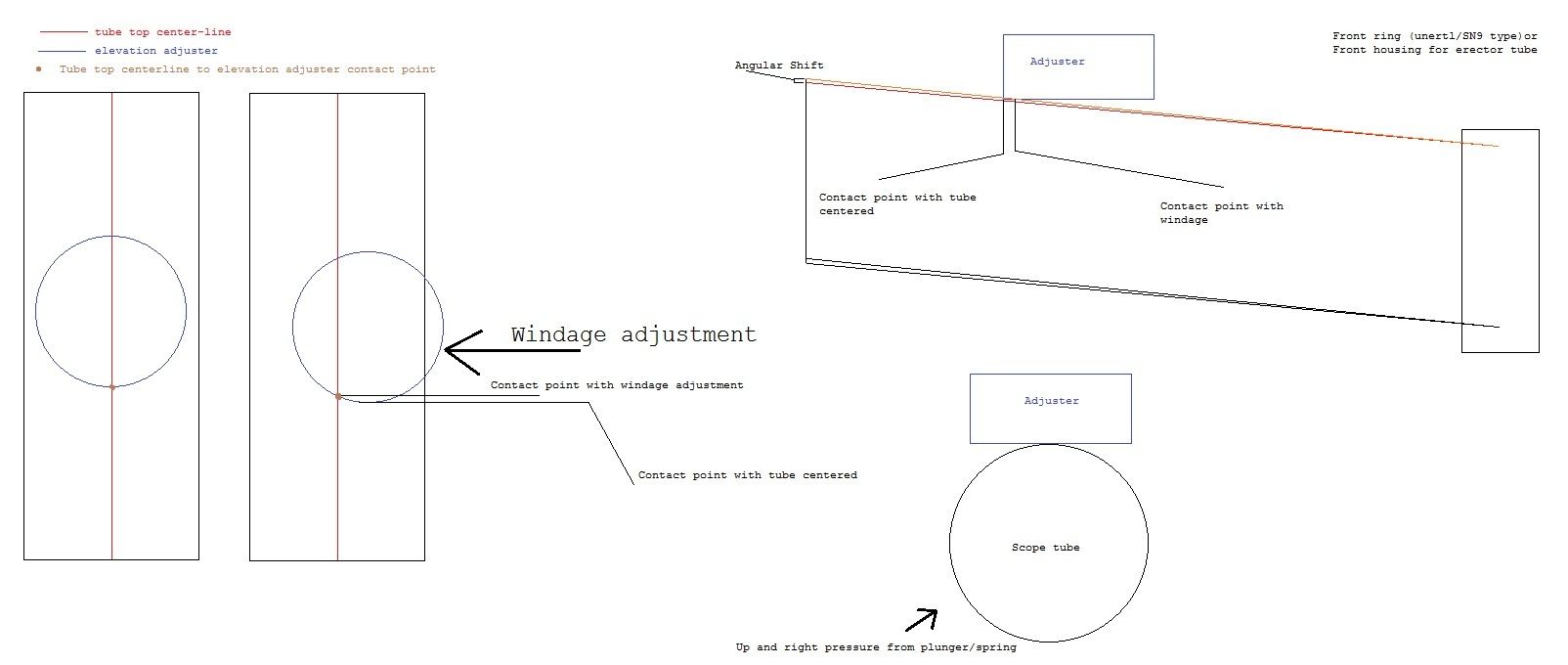

The issue is that your main scope tube is round (cylinder), and your adjustors, where they contact the tube are also round, and flat on the bottom (cylinders). Assuming the tube is perfectly centered in the adjusters, then the top centerline of the scope and the right centerline of the scope make contact along a straight line, the diameter of the face of the adjusters. In this state, if the scope is pushed left or right, or up/down (one OR the other), it will maintain a line of contact (although perhaps now a secant that it is pushed off of the adjuster centerline diameter) with one of the adjusters, but will meet at an angle with the other, making contact at only 1 point. If you adjust BOTH windage and elevation, the tube only touches each adjuster at 1 point. Now that my tube is only contacting the elevation adjuster at 1 point because the tube is at a down-angle (top of the tube contacts the very rear of the adjuster, which is parallel to the rifle bore center axis, not parallel to the tube), let's make a windage adjustment. The top of the scope tube rolls around the circumference of the rear-bottom of the adjuster. Consider what just happened.

(Bigger pic: http://img.photobucket.com/albums/v257/Erkorene/Scopeadjusterissue.jpg )

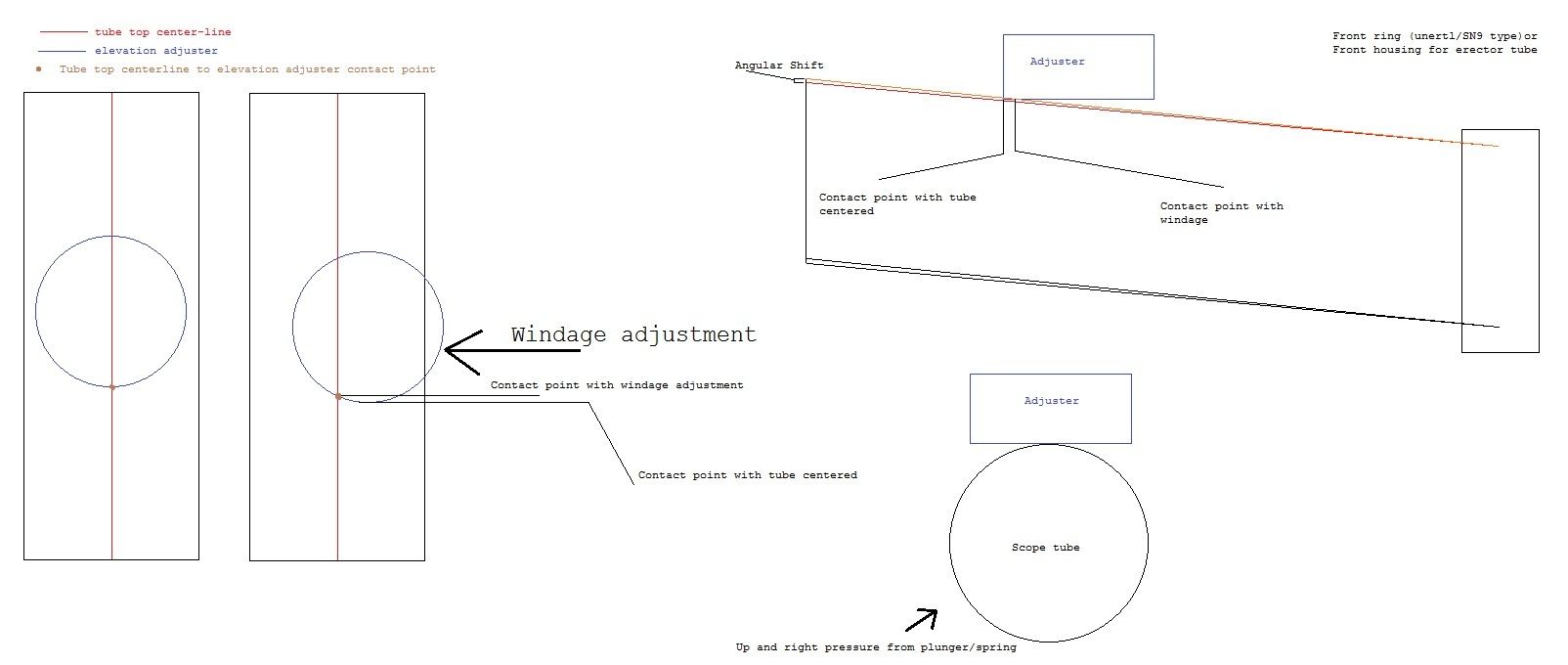

We created a difference in the length between contact point of the rear adjuster to the tube and the front ring, thus inducing an elevation offset-- by operating my windage knob.

Does anyone follow? Has anyone run into this issue, or is there something I'm not seeing to eliminate or off set it?

For ease of visualization, I'll talk about Unertl external adjusted type scopes (US Optics SN-9 included), however, the same principle is in effect (to my knowledge) on erector tubes inside a scopes main-tube housing.

The issue is that your main scope tube is round (cylinder), and your adjustors, where they contact the tube are also round, and flat on the bottom (cylinders). Assuming the tube is perfectly centered in the adjusters, then the top centerline of the scope and the right centerline of the scope make contact along a straight line, the diameter of the face of the adjusters. In this state, if the scope is pushed left or right, or up/down (one OR the other), it will maintain a line of contact (although perhaps now a secant that it is pushed off of the adjuster centerline diameter) with one of the adjusters, but will meet at an angle with the other, making contact at only 1 point. If you adjust BOTH windage and elevation, the tube only touches each adjuster at 1 point. Now that my tube is only contacting the elevation adjuster at 1 point because the tube is at a down-angle (top of the tube contacts the very rear of the adjuster, which is parallel to the rifle bore center axis, not parallel to the tube), let's make a windage adjustment. The top of the scope tube rolls around the circumference of the rear-bottom of the adjuster. Consider what just happened.

(Bigger pic: http://img.photobucket.com/albums/v257/Erkorene/Scopeadjusterissue.jpg )

We created a difference in the length between contact point of the rear adjuster to the tube and the front ring, thus inducing an elevation offset-- by operating my windage knob.

Does anyone follow? Has anyone run into this issue, or is there something I'm not seeing to eliminate or off set it?