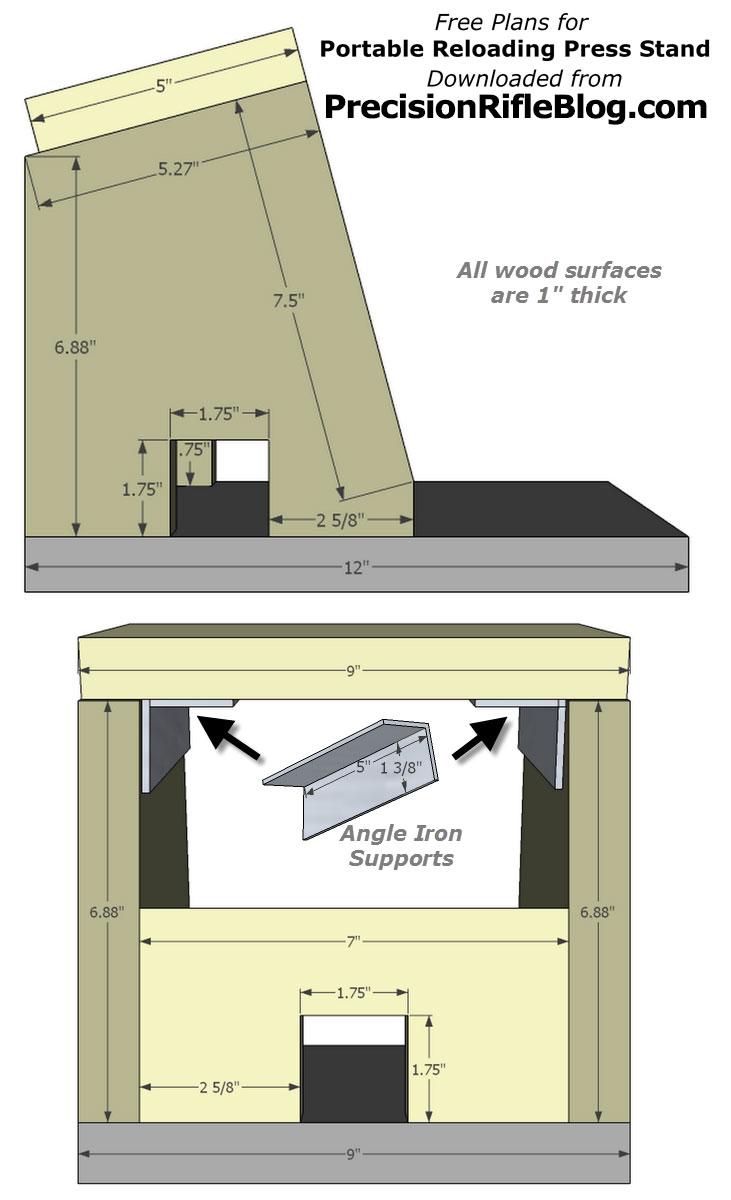

Portable Reloading Press Plans

I wanted to create a portable reloading press stand that I could mount my full-size RCBS Rockchucker...

I have very little space and plan on moving around quite a bit over the next decade. Done right, could this support a Dillon? I want to be able to clamp this down onto whatever surface I have available.