Re: Crowning Barrels.

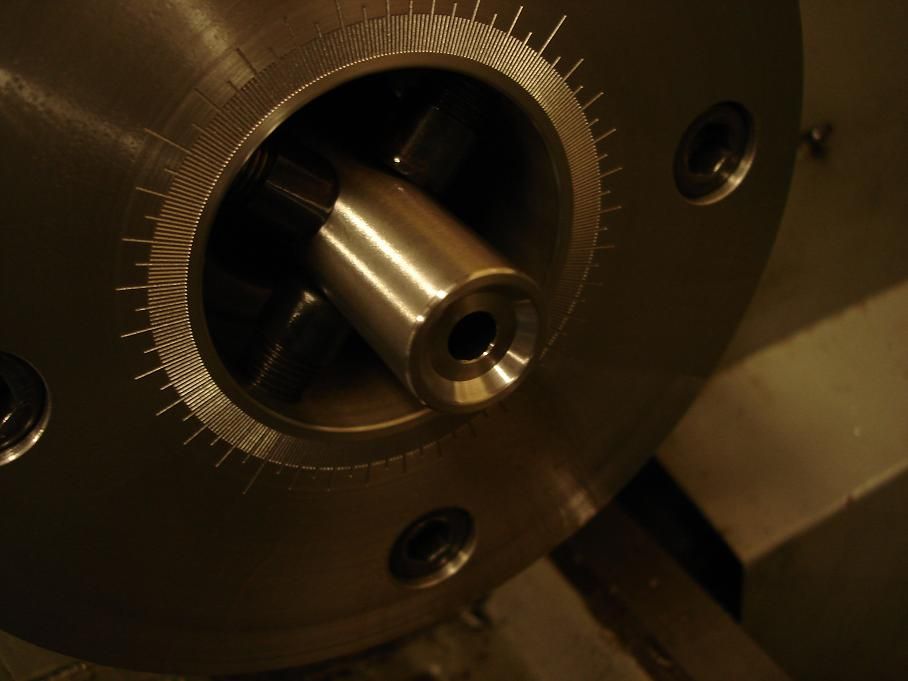

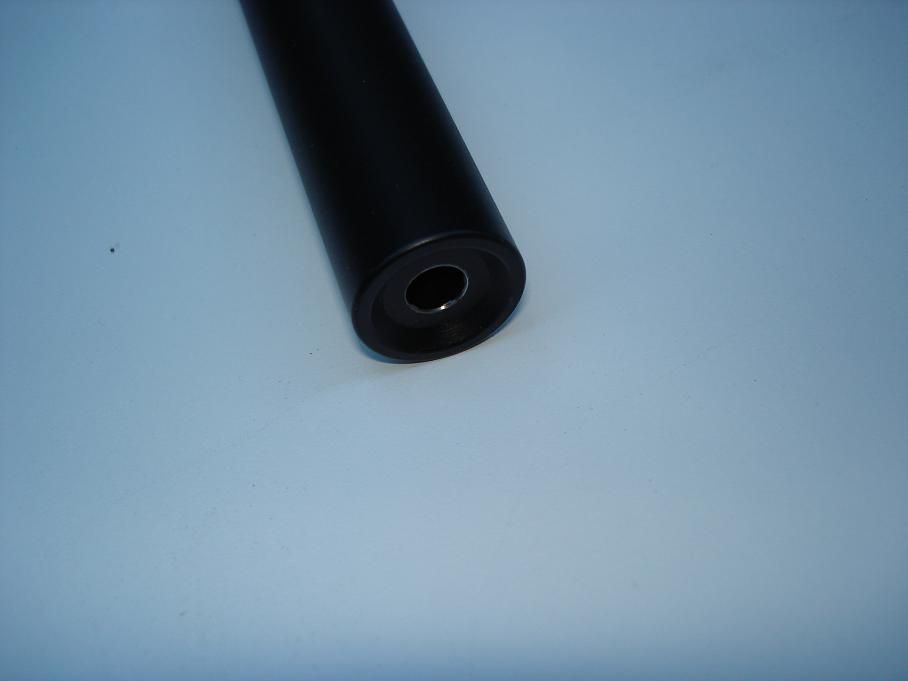

This tool shown in a video produces NO chatter in principle because of the carbide (serrated) cutting blades design and some other things incorporated into design. Serrated cutting blades, which in combination form numerous active cutting edges, overlap each other, helping to produce good finish, and also, eliminate tendency of the cutting edges to "dig" into the metal.

It's been around for nearly 10 years, and anybody interested can search the net for references and additional info. It's been tested an all kinds of barrels, chrome lined, stainless, alloy steel, whatever.

In regard to concentrically - it uses expandable non-rotating precision pilots, which is a completely different arrangement in comparison to typical piloted cutter. Pilots are expandable up to 0.010", so one pilot, say, 5.5 mm, covers all existing 0.22 calibers, rimfire and centerfire, including 5.45 mm on the low end. As the result, concentricity of the crown formed by this tool is typically comparable to the crown machined on the lathe by the operator who knows what he is doing, and much better in all other cases.

The main difference is that it takes 5 to 7 minutes on average to do it, as opposed to much longer time needed for lathe setup. Also, no disassembly of the firearm is needed. Just do a search for "Dave Manson muzzle crowning tool".

Out of approximately 800 tool kits, both professional type and military rifle ones, sold by Dave so far, at least half was bought by professional gunsmiths, including some well known guys. They buy these tools because they can make nice crowning jobs in 5-7 minutes and get paid their typical $35-$50, which makes them $250+ per hour for crowning jobs. The other guys buy it cause they do not have lathe, do not need to know how to use it or do the correct setup, and they can still make high quality crowns by themselves. Rifles, pistols, revolvers, whatever. Also, Dave has a cutter setup for shotguns, including double barrel ones. I have quite a bit of lathe experience myself, but would not want to set up double barrel in a chuck..

I'm not selling this tool here, but I'm associated with Dave Manson, and just wanted to let you know a bit more. If you're interested, call Dave Manson Precision Reamers and mention my name - Boris, and he'll treat you particularly nice, although he treats every customer nice. If you plan to visit 2011 Shot Show, you can also see live demonstration of this tool. There is a 30% chance you'll want to buy it right on the spot - it's been my observation that every third of the individuals watching the demonstration bought it.