Re: Cutting fluid for flush reaming

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">what size reservoir are most running? how many gallons of fluid are sitting in it at idle? i'm trying to get an idea of what i need to make for this. i don't want to make something too small that i have to shut down the op while waiting for the fluid to migrate back to the tank. then again, i don't want to buy 20 gallons of oil when 5 will work. </div></div>

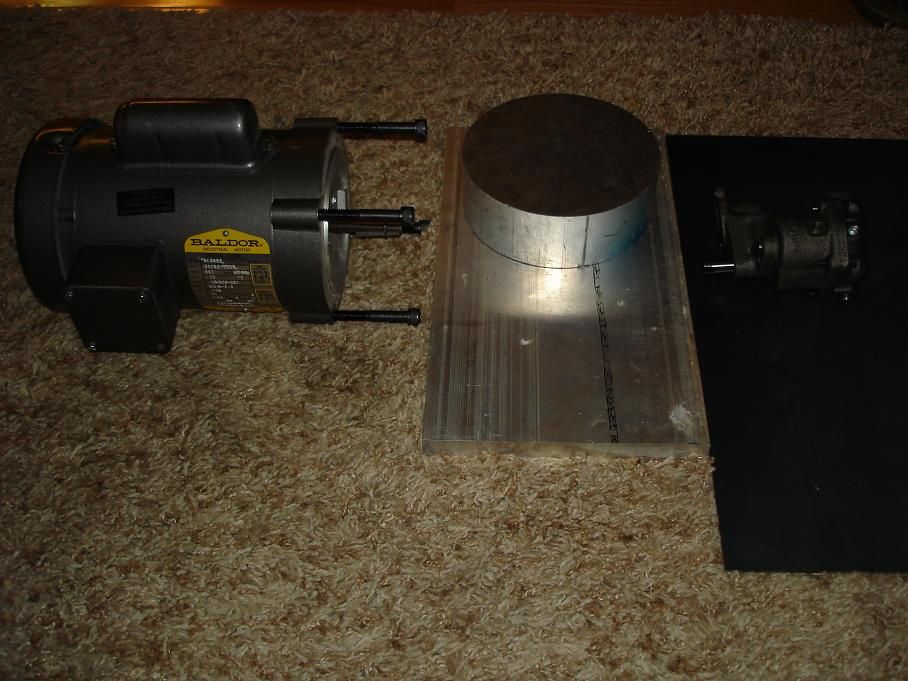

When I switched over to the new machine the large chip pan held quite a bit of the coolant before it drained back into my 5 gallon reservoir. Basically, the pump emptied approx 3 gallons pretty quick and ran dry. I purchased an 8 gallon plastic storage tote from Lowes and added a combined 3 gallons of Rigid Dark threading oil and EP Tap Magic Extra. The tote from Lowes was an up grade from my 5 gallon orange Home Depot bucket

Hey, a guy's gotta splurge sometimes.

The change worked great, no more empty reservoir and it works like a charm.

RAD, your avitar looks like it's on acid.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">what size reservoir are most running? how many gallons of fluid are sitting in it at idle? i'm trying to get an idea of what i need to make for this. i don't want to make something too small that i have to shut down the op while waiting for the fluid to migrate back to the tank. then again, i don't want to buy 20 gallons of oil when 5 will work. </div></div>

When I switched over to the new machine the large chip pan held quite a bit of the coolant before it drained back into my 5 gallon reservoir. Basically, the pump emptied approx 3 gallons pretty quick and ran dry. I purchased an 8 gallon plastic storage tote from Lowes and added a combined 3 gallons of Rigid Dark threading oil and EP Tap Magic Extra. The tote from Lowes was an up grade from my 5 gallon orange Home Depot bucket

Hey, a guy's gotta splurge sometimes.

The change worked great, no more empty reservoir and it works like a charm.

RAD, your avitar looks like it's on acid.