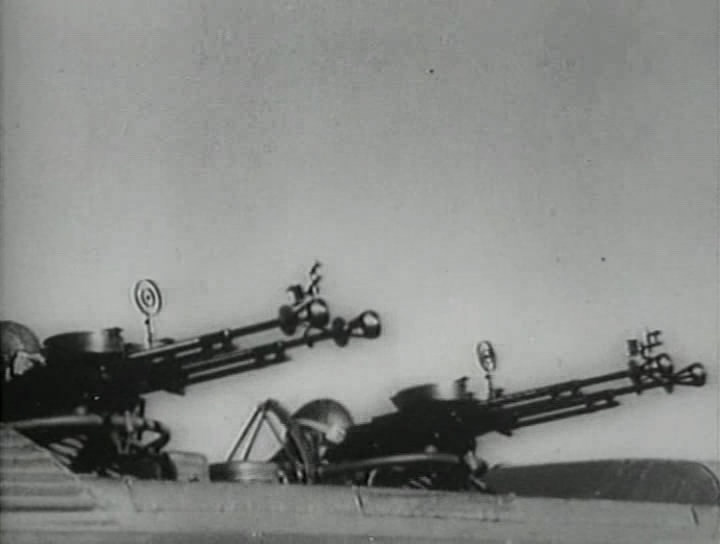

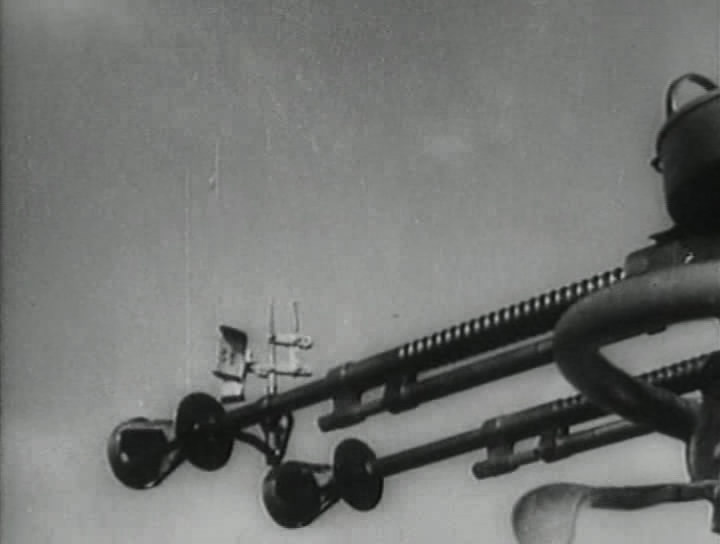

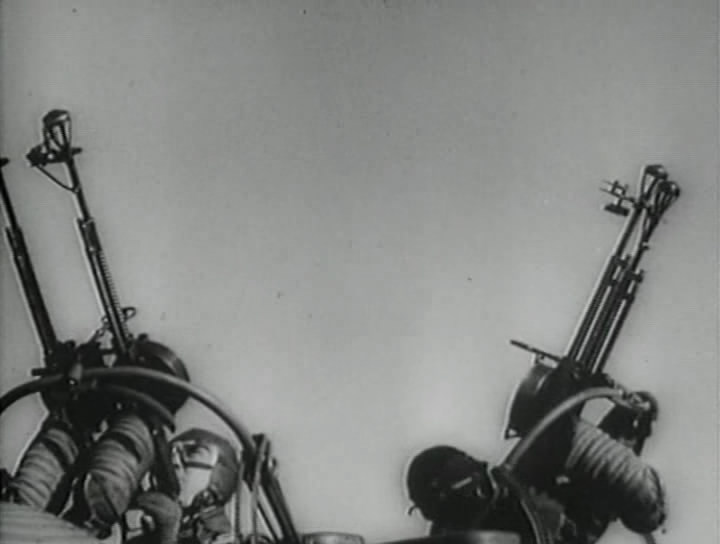

Has anyone ever seen one of these? All I can tell is there are some illustrations of what it looked like from some old Soviet manuals. Maybe a pic or two of one in a museum somewhere (missing its sights).

According to wiki they were produced from 1928 to 1930 before being replaced with a couple better options like the shkas.

I became sorta fascinated with it, specifically the wind vane front sight which I never knew existed but turns out were on quite a few aircraft mounted machine guns of the early open top biplane ww1 era, such as on the American Lewis mk1

Well I have a dp28 that never really

did anything me, kinda wierd kinda ugly etc so I decided I was gonna try and convert it into a DA.

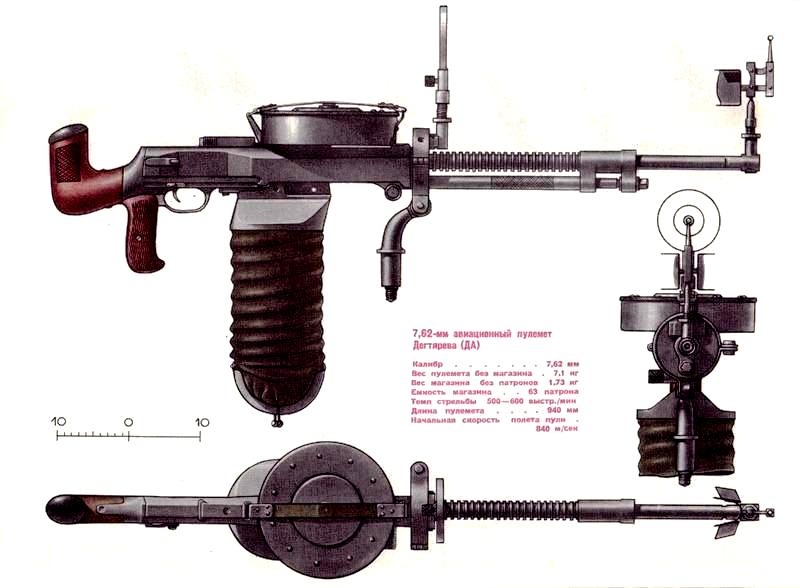

Here is the illustration I am using as a guide, and the semi auto dp28 that’s getting hacked up

I will try and share the project below (it’s almost done so as time permits to post up some photos I took along the way

According to wiki they were produced from 1928 to 1930 before being replaced with a couple better options like the shkas.

I became sorta fascinated with it, specifically the wind vane front sight which I never knew existed but turns out were on quite a few aircraft mounted machine guns of the early open top biplane ww1 era, such as on the American Lewis mk1

Well I have a dp28 that never really

did anything me, kinda wierd kinda ugly etc so I decided I was gonna try and convert it into a DA.

Here is the illustration I am using as a guide, and the semi auto dp28 that’s getting hacked up

I will try and share the project below (it’s almost done so as time permits to post up some photos I took along the way