Ok, first off... don't laugh at my video skills, and my nasal congestion (been sick with the crud for almost a month now). Posted this on the Creedmoor forum and thought I'd throw it over here too.

This is a reloading press riser mount that I built in order to get my presses up a little higher and to allow me to not have to have two presses mounted to the bench side by side taking up valuable space. Also, it keeps me from having to remove/replace my presses if I just use a single location. I hate having to find a place to store the press that I am not using. It is 1/2" 6061 aluminum and the top pivots which allows me access to either press in just a matter of seconds. It took me a fair amount of time to build and if I were to do it again I would just weld the pieces instead of drilling-tapping-bolting it together. In fact, I'd probably just make it out of 1/8" or 3/16" steel and press brake the main riser body. As it is, it is VERY stout!! The top is effectively 1 inch thick (two 1/2" plates stacked).

Video of it in action

DIY Rotating Reloading Press Riser - YouTube

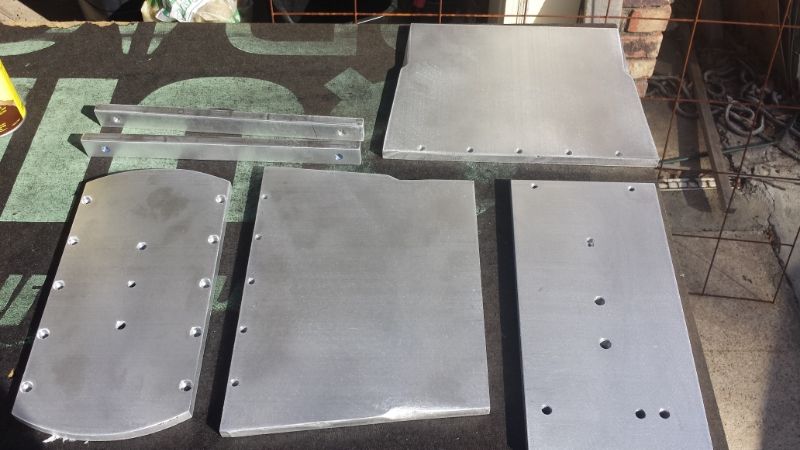

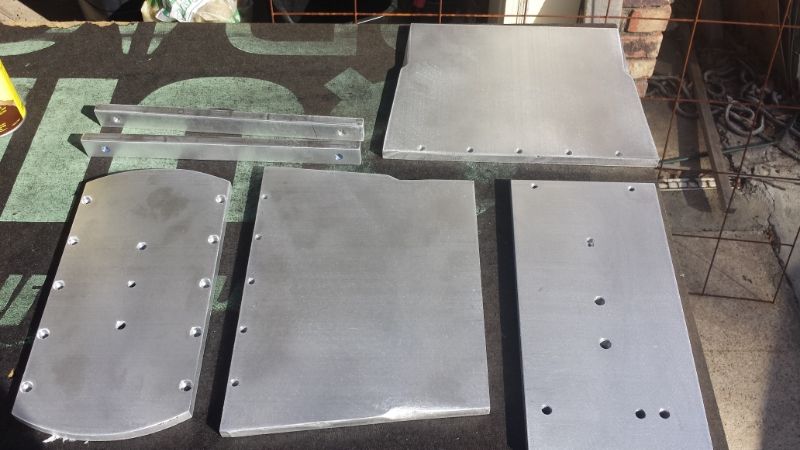

Parts:

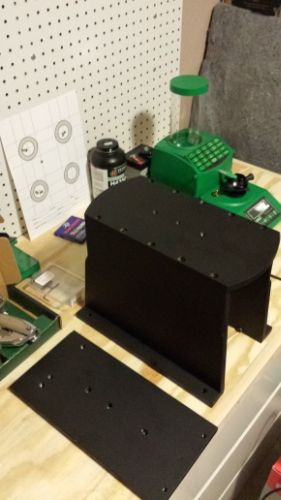

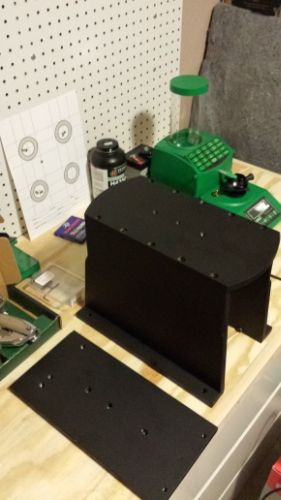

Painted with Alumahyde

Progessive in front:

Single Stage in front:

This is a reloading press riser mount that I built in order to get my presses up a little higher and to allow me to not have to have two presses mounted to the bench side by side taking up valuable space. Also, it keeps me from having to remove/replace my presses if I just use a single location. I hate having to find a place to store the press that I am not using. It is 1/2" 6061 aluminum and the top pivots which allows me access to either press in just a matter of seconds. It took me a fair amount of time to build and if I were to do it again I would just weld the pieces instead of drilling-tapping-bolting it together. In fact, I'd probably just make it out of 1/8" or 3/16" steel and press brake the main riser body. As it is, it is VERY stout!! The top is effectively 1 inch thick (two 1/2" plates stacked).

Video of it in action

DIY Rotating Reloading Press Riser - YouTube

Parts:

Painted with Alumahyde

Progessive in front:

Single Stage in front: