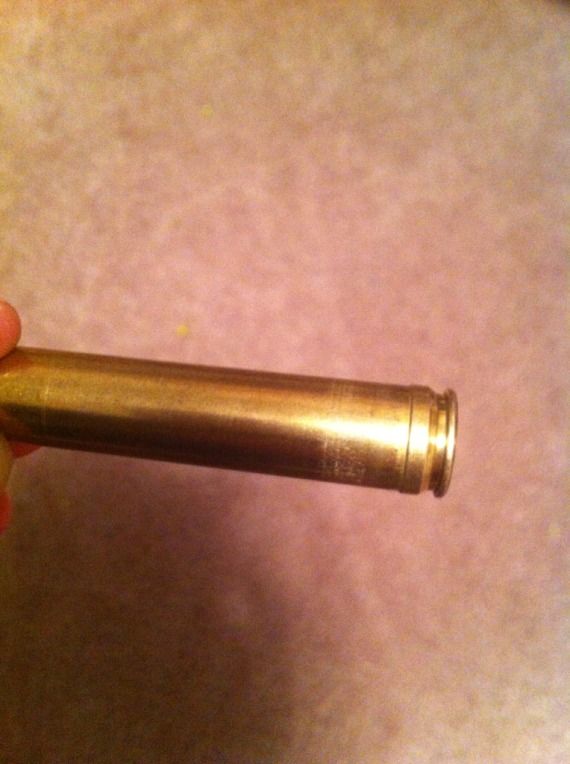

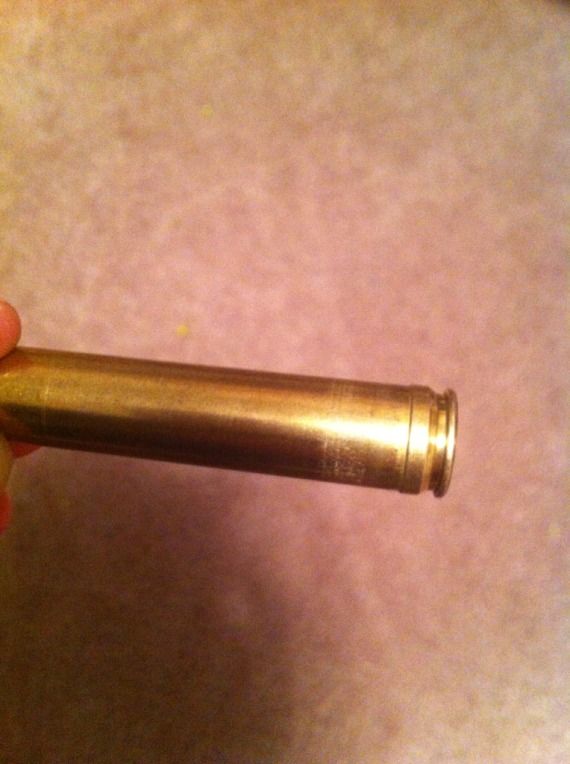

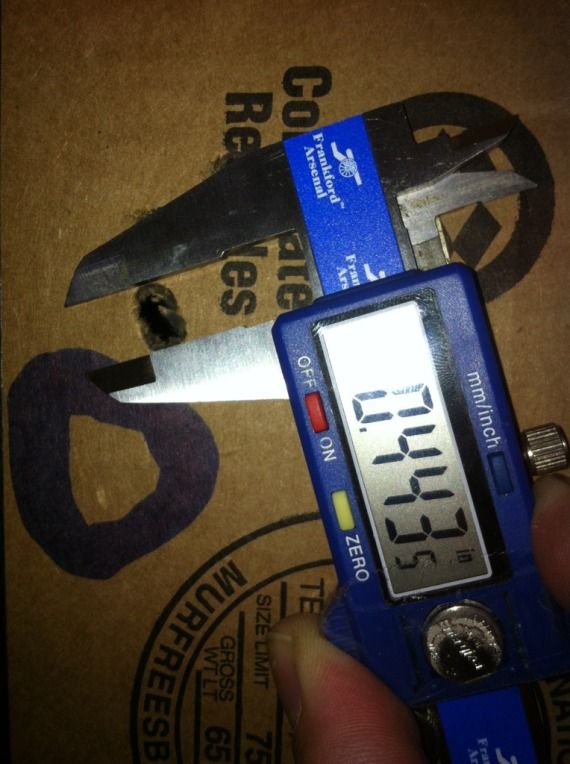

This is a rifle that was just built off a trued Remington action. It's thad 35 rounds fired through it so far. I see the mark you are referring to Chad, if something is sticking in the chamber how can it be fixed? Also, I just finished fl resizing these cases and loading them and now they are hard to chamber. I can stick my finger at the rim of the case when it's in the chamber and feel that it is not going all the way in. I have to slam the bolt on the round to get it to close, but the downward stroke when bolting is not hard like it's in a bind. It appears to me that there is a slight bump right in front of the belt that doesn't allow the case to go completely in the chamber. Do I have two different things going on here?

I suspect you do have two different things going on there - first do as Chad suggests and check the chamber for grooves. Sometimes that click is also indicative of extraction issues, timing of the bolt handle. If the stock action was trued, that is likely part of it.

Since you indicate the hard chambering is only with reloaded rounds, that is a secondary issue. A lot of times, usually with hot loads, or approaching hot loads, full length resizing is not enough to get a belted mag to chamber again. There is a die, a collet die is what it is called, that squeezes the case, just forward of the belt, that will fix the tight bolt close. You know, that you need to marry the brass to the rifle, after you get your dies set, or you are going to be seeing pretty short brass life, from constant big resizing moves. The perfect resize, is just enough to allow chambering, without moving the shoulder any more than is necessary.

You might also think about changing the chamber, such that the shoulder, rather than the belt, is setting the headspace. Not SAAMI compliant, but since you reload you could do it easily. Some guys think it makes the rifle shoot a bit better, me, I am not as convinced.