During this covid lock down I decided to try chasing down the accuracy and reliability issues I've been having with a newly built 80% LR/DPMS 308.

Initially I started this thread looking for some input on a strange bolt issue. I'm now updating it to be sort of a build/trouble shooting large frame DPMS thread. I've seen so many of these started and never run to ground. This will be soup to nuts polishing the turd!

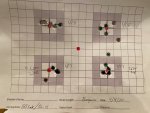

It shoots a consistent 3-4moa 5 shot group @100YDS no matter the ammo. typically 3 shots will be within about 1.5 moa & then at least 2 flyers (mostly lateral).

Tried Win White box 147 to break it in, then FGMM 168, Hornady 178 BTHP, & Lake city M118 173grn.

Shooting done off bench with Atlas bipod and rear bag.

The reliability issues have been bolt override where the case is ejected & next round is partially chambered & smashed against feed ramps with bolt ontop of case (like a short stroke, but it's not).

Build specs: Includes some initial issues (This will be updated as parts were changed).

LR 308 DPMS Gen 1

All parts were new.

I suspect the Toolcraft bolt has a heat treat issue.

FYI - not bashing Toolcraft I have another one of there BCG's in a 6.8 SPC2 and like it. Their Customer service is very good. I sent them the 2 pics below and they replied within the hour with a return shipping label & said it would be replaced.

Anyone have experience with this? Do you think the imprint on the lugs not meshing up perfectly with extension would cause flyers?

The dual ejector BCG was not my first choice, but I wanted the small firing pin & that is the only way I could get it from Toolcraft. I don't think the dual ejectors serve any purpose and may also hurt accuracy.

Could it be bolt thrust?

Chamber polished to smooth (doesn't look to smooth)?

Still scratching my head, hell it's just a 308 with 120 rounds of factory ammo through it. (updated down thread)

Did some searching on the web and found one other guy that tried one of these large frame Bergara barrels in 308. He was shooting 3-4 moa and gave up on it.

I'm also suspicious of the barrel because of the modifications required to make the Centurion barrel nut fit Bergara's extension. (also updated down thread)

The barrel extension lugs look perfect, but I'm not putting a new bolt back on this barrel. Hell I can't in good conscience sell the barrel cheap in the PX.

Guess I should give Craddock a call and order a barrel. (again updated down thread)

Head space was checked, barrel scoped and slugged, gas turned down, tried single feeding, tried 2 different scope/combos, nut and bolted everything with a fat wrench, etc. Still 3-4moa with lateral flyers. WTF

Recoil is very soft in my opinion, although I have no other large frame to compare it to.

I can ease the bolt into battery with just spring pressure riding the charging handle down & no hang ups whatsoever.

Initially I started this thread looking for some input on a strange bolt issue. I'm now updating it to be sort of a build/trouble shooting large frame DPMS thread. I've seen so many of these started and never run to ground. This will be soup to nuts polishing the turd!

It shoots a consistent 3-4moa 5 shot group @100YDS no matter the ammo. typically 3 shots will be within about 1.5 moa & then at least 2 flyers (mostly lateral).

Tried Win White box 147 to break it in, then FGMM 168, Hornady 178 BTHP, & Lake city M118 173grn.

Shooting done off bench with Atlas bipod and rear bag.

The reliability issues have been bolt override where the case is ejected & next round is partially chambered & smashed against feed ramps with bolt ontop of case (like a short stroke, but it's not).

Build specs: Includes some initial issues (This will be updated as parts were changed).

LR 308 DPMS Gen 1

All parts were new.

- American made tactical DPMS 80% lower

- Davidson Defense LR-308 Billet Upper Receiver .308 Ar (DPMS High Profile Style) This one matches lower and has forward assist in correct location.

- Barrel - Bergara 18" 308 Win. 1/10 SS mid length gas with .750 GB, 5/8-24 thread

- VG6 Gamma 300 BLK 2 port muzzle break with shim kit

- SLR Sentry 7 .750 adjustable gas block 4 screw clamp on.

- melonited mid length gas tube from SLR

- Centurion CMR 12" hand gaurd . Barrel nut did not fit over barrel extension shoulder (opened nut ID .040) Barrel nut also bottomed on upper before tightening barrel (shortened barrel nut .060) Makes me wonder about Barrel/extension. Shouldn't have had to modify barrel nut from Centurion?

- Std upper completion parts (dust cover & forward assist)

- Aero lower parts kit less FCG

- Trigger is Larue MBT-2s 2.5lb 1st and 2lb second stage

- BCG is Toolcraft nitrite with small firing pin & double ejector (didn't want double ejector but that's the only way to get small firing pin for 6.5 conversion later.

- Heavy Buffers XH carbine buffer 8.5oz

- ArmaLite #EA1095 rifle length buffer spring

- Magpul UBR Gen 2 stock with A5 length tube

- Noveske branded Geissele super charging handle

- Wilson Combat/BCM mod 3 grip

- trigger shims.com for front take down pin - lower shimming

- DPMS 10 round steel mags, Magpul 10 rnd mag, Magpul 20 rnd mag, & Magpul 25 rnd mag. Note: there are slight differences between the magpuls.

- Athlon Ares BTR 2.5-15 x 50 in Eotech rings

I suspect the Toolcraft bolt has a heat treat issue.

FYI - not bashing Toolcraft I have another one of there BCG's in a 6.8 SPC2 and like it. Their Customer service is very good. I sent them the 2 pics below and they replied within the hour with a return shipping label & said it would be replaced.

Anyone have experience with this? Do you think the imprint on the lugs not meshing up perfectly with extension would cause flyers?

The dual ejector BCG was not my first choice, but I wanted the small firing pin & that is the only way I could get it from Toolcraft. I don't think the dual ejectors serve any purpose and may also hurt accuracy.

Could it be bolt thrust?

Chamber polished to smooth (doesn't look to smooth)?

Still scratching my head, hell it's just a 308 with 120 rounds of factory ammo through it. (updated down thread)

Did some searching on the web and found one other guy that tried one of these large frame Bergara barrels in 308. He was shooting 3-4 moa and gave up on it.

I'm also suspicious of the barrel because of the modifications required to make the Centurion barrel nut fit Bergara's extension. (also updated down thread)

The barrel extension lugs look perfect, but I'm not putting a new bolt back on this barrel. Hell I can't in good conscience sell the barrel cheap in the PX.

Guess I should give Craddock a call and order a barrel. (again updated down thread)

Head space was checked, barrel scoped and slugged, gas turned down, tried single feeding, tried 2 different scope/combos, nut and bolted everything with a fat wrench, etc. Still 3-4moa with lateral flyers. WTF

Recoil is very soft in my opinion, although I have no other large frame to compare it to.

I can ease the bolt into battery with just spring pressure riding the charging handle down & no hang ups whatsoever.

Attachments

Last edited: