Hello everyone, we've been busy at work getting caught up and stocking up on top quality parts.

-We are looking at less than one month build times for complete builds. Some builds being placed within the next week could be done in as little as one week from the time of arrival.

-Misc. work will take 2-7 days.

-Bolt knob installs are 1-3 days as usual.

We are now accepting Visa and Mastercard.

Here are some of the parts we have in stock and ready for purchase:

*Defiance Deviant short action .308 bolt face, Right hand, AW mag cut, swept handle, Ready to rock.

*Mcmillan A5 with Adjustable cheek piece. Can be inlet'd for any Rem700(short or long, left or right hand). We have many more Mcmillan flat tops arriving soon. A5s, A4s, and HTGs. Some adjustable, some not.

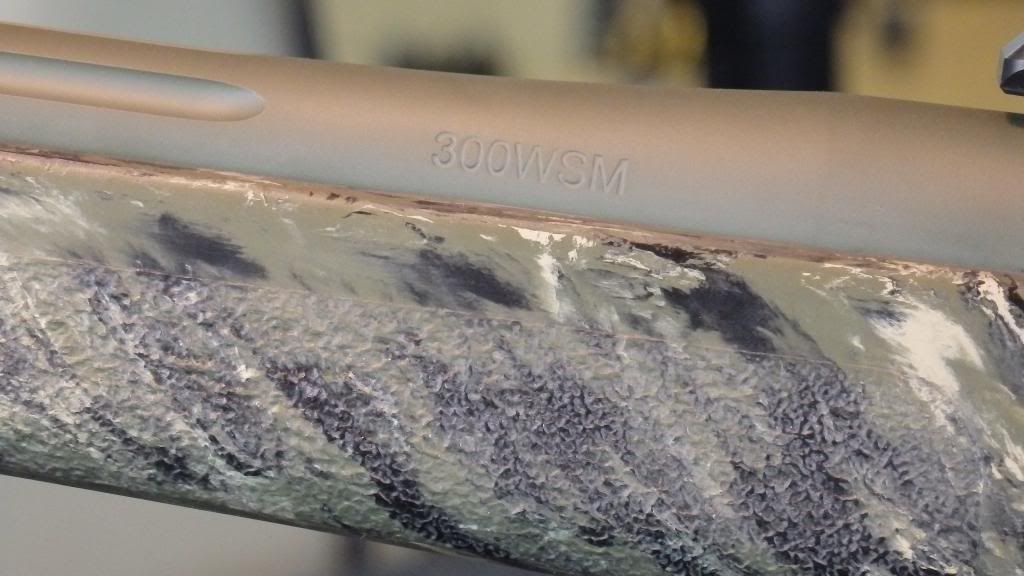

*Bartlein, Brux, Rock creek, and Krieger Stainless Match barrels in the fastest common twist rates, in both M24 and Rem Varmint contour, in every caliber. We also have a few #5s and #4s.

*Pretty much any Detachable Box Magazine system you want is in stock.

*Badger Thruster muzzle brakes, FTE brakes in every size, APA brakes(Lil Jimmy and both Bastards)

We stock the parts we see people use the most, and that work the best.

Call us for a build and be shooting it within a month!

-We are looking at less than one month build times for complete builds. Some builds being placed within the next week could be done in as little as one week from the time of arrival.

-Misc. work will take 2-7 days.

-Bolt knob installs are 1-3 days as usual.

We are now accepting Visa and Mastercard.

Here are some of the parts we have in stock and ready for purchase:

*Defiance Deviant short action .308 bolt face, Right hand, AW mag cut, swept handle, Ready to rock.

*Mcmillan A5 with Adjustable cheek piece. Can be inlet'd for any Rem700(short or long, left or right hand). We have many more Mcmillan flat tops arriving soon. A5s, A4s, and HTGs. Some adjustable, some not.

*Bartlein, Brux, Rock creek, and Krieger Stainless Match barrels in the fastest common twist rates, in both M24 and Rem Varmint contour, in every caliber. We also have a few #5s and #4s.

*Pretty much any Detachable Box Magazine system you want is in stock.

*Badger Thruster muzzle brakes, FTE brakes in every size, APA brakes(Lil Jimmy and both Bastards)

We stock the parts we see people use the most, and that work the best.

Call us for a build and be shooting it within a month!