Well, I can't say I'm proud of this, but I wanted to post it to help others and myself learn from it. The offending load recipe was:

Cal: 7mm RM

Bullet: 184gr Berger F-Open

Charge: 70.7gr VV N570

Jump: .010"-.012" off the lands

Other: Nosler brass; Win LRM primer; 28" 1:8.5 twist bbl

I was fine tuning this load a few days ago, and blew my first primer. I was testing three loads in two nodes that showed promise from a few weeks ago--the one listed above, a slightly heavier (70.9gr) variant, along with a lower node using 60.9 gr of N570. None of the rounds showed pressure signs that I could see (nor did slightly heavier charges I tried in the earlier test round). However, the original test was done in ~75* weather, whereas the one from a few days ago was done in ~95* weather (although under cover, out of direct sunlight). The headstamps of the 20 rounds in question are pictured below, although I obviously didn't fire the last two after the primer blew on #18.

As you can see in the picture, the one that blew has a clear ejector mark, but none of the previous 17 rounds did. On the one or two before it, I thought I felt some stickiness in the bolt lift, but I wasn't sure if it was my imagination, since I hadn't had any trouble with this load up to this point, or with a couple of test loads that were a little bit heavier. I also didn't see anything on the case head indicating I should stop. The one that blew was #48 fired that day. For what it's worth, I had been using a home made barrel cooler between each 5 shot string to manage the heat buildup, and shooting the three loads being tested round robin.

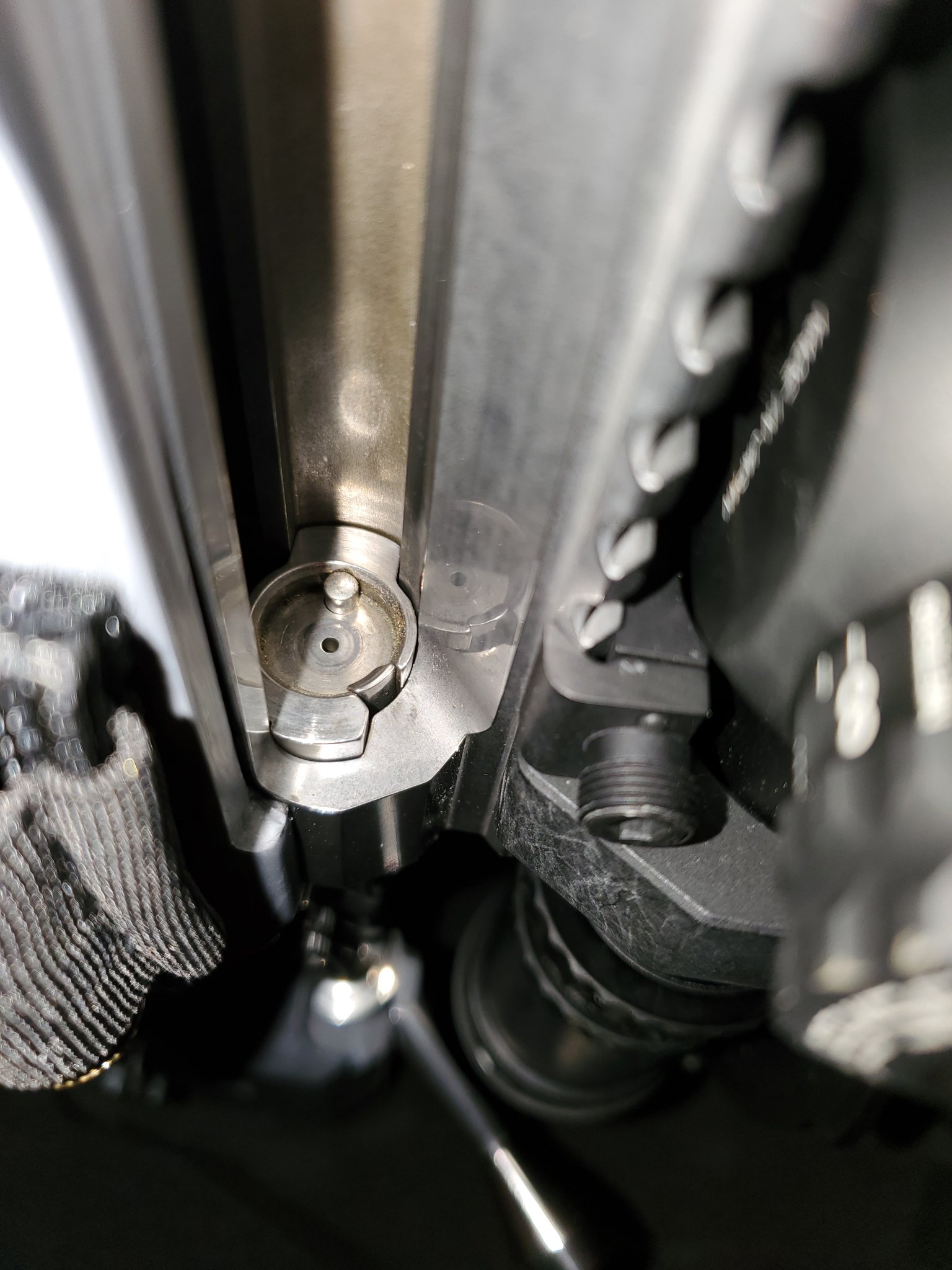

Here is a picture of the bolt face after the shot:

I got the load recipe from Berger over the phone, since there isn't data published for the 184gr F-Open bullets yet. Naturally, they cautioned that I should watch for pressure signs, which I thought I was doing, but apparently not. To my admittedly untrained eye, it doesn't look like I damaged the bolt face, but I'd appreciate a second opinion. As for the brass,

I'm assuming that I should trash the brass with the blown primer, even if the pocket would still hold one(?), and maybe the others as well(?)

Maybe it was just the extra 20* of heat that got me that day. Thanks for any advice, and hopefully others can learn from my mistake!

Cal: 7mm RM

Bullet: 184gr Berger F-Open

Charge: 70.7gr VV N570

Jump: .010"-.012" off the lands

Other: Nosler brass; Win LRM primer; 28" 1:8.5 twist bbl

I was fine tuning this load a few days ago, and blew my first primer. I was testing three loads in two nodes that showed promise from a few weeks ago--the one listed above, a slightly heavier (70.9gr) variant, along with a lower node using 60.9 gr of N570. None of the rounds showed pressure signs that I could see (nor did slightly heavier charges I tried in the earlier test round). However, the original test was done in ~75* weather, whereas the one from a few days ago was done in ~95* weather (although under cover, out of direct sunlight). The headstamps of the 20 rounds in question are pictured below, although I obviously didn't fire the last two after the primer blew on #18.

As you can see in the picture, the one that blew has a clear ejector mark, but none of the previous 17 rounds did. On the one or two before it, I thought I felt some stickiness in the bolt lift, but I wasn't sure if it was my imagination, since I hadn't had any trouble with this load up to this point, or with a couple of test loads that were a little bit heavier. I also didn't see anything on the case head indicating I should stop. The one that blew was #48 fired that day. For what it's worth, I had been using a home made barrel cooler between each 5 shot string to manage the heat buildup, and shooting the three loads being tested round robin.

Here is a picture of the bolt face after the shot:

I got the load recipe from Berger over the phone, since there isn't data published for the 184gr F-Open bullets yet. Naturally, they cautioned that I should watch for pressure signs, which I thought I was doing, but apparently not. To my admittedly untrained eye, it doesn't look like I damaged the bolt face, but I'd appreciate a second opinion. As for the brass,

I'm assuming that I should trash the brass with the blown primer, even if the pocket would still hold one(?), and maybe the others as well(?)

Maybe it was just the extra 20* of heat that got me that day. Thanks for any advice, and hopefully others can learn from my mistake!

Last edited: