I have a new Forster Co-Ax press that under use, results in the case (223 Remington) being quite a bit off center from the die. Enough so that the resizing ball on the Redding FL die catches on the edge of the case sometimes and tries to crush the neck edge. You can nudge the case slightly to the left and all is fine, but do not want to do that all the time.

Under closer observation, it is obvious that when the jaws close around the case, the case tilts to the right from where it was sitting unclamped. I tried various brass, new and once fired, with no difference. The jaws ARE slightly to the right in a resting position when closed with no case and not held open by the tapered screw (photo #1).

I called Forster. They said to snip a coil of a jaw spring to cause the jaws to move the left. A snipped coil on the spring may fix this, but am surprised it is this way for a brand new press. I will order more springs before cutting anything.

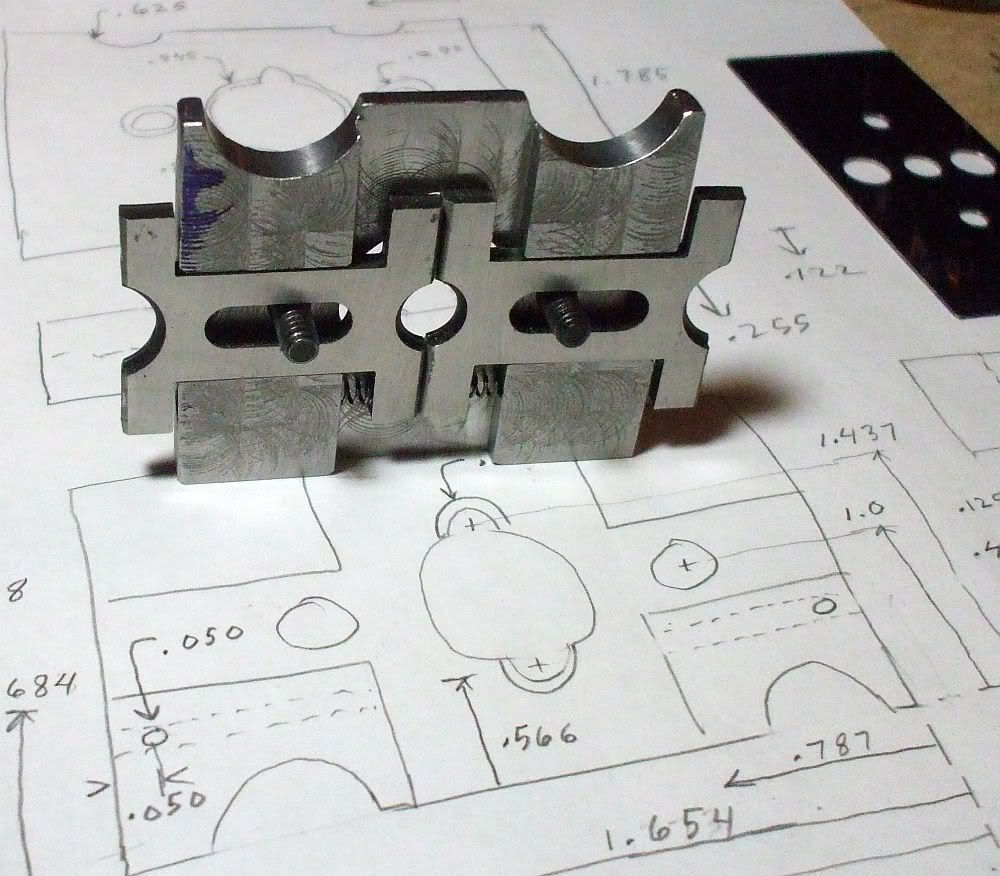

The first pic is a closeup of the jaws without the tapered screw holding them open. Hard to see, but the jaws are slightly to the left of the primer hole.

The second photo clearly shows the misalignment.

The third photo shows the case clamped in the jaws, ready to raise.

The fourth photo shows the case sitting on the shell plate, but not clamped.

Notice how the case tilts slightly to right in photo #3 from where it is photo #4.

I am new to reloading and this press, so any guidance or wisdom from others on how best to deal with this is welcome.

- Phil

Under closer observation, it is obvious that when the jaws close around the case, the case tilts to the right from where it was sitting unclamped. I tried various brass, new and once fired, with no difference. The jaws ARE slightly to the right in a resting position when closed with no case and not held open by the tapered screw (photo #1).

I called Forster. They said to snip a coil of a jaw spring to cause the jaws to move the left. A snipped coil on the spring may fix this, but am surprised it is this way for a brand new press. I will order more springs before cutting anything.

The first pic is a closeup of the jaws without the tapered screw holding them open. Hard to see, but the jaws are slightly to the left of the primer hole.

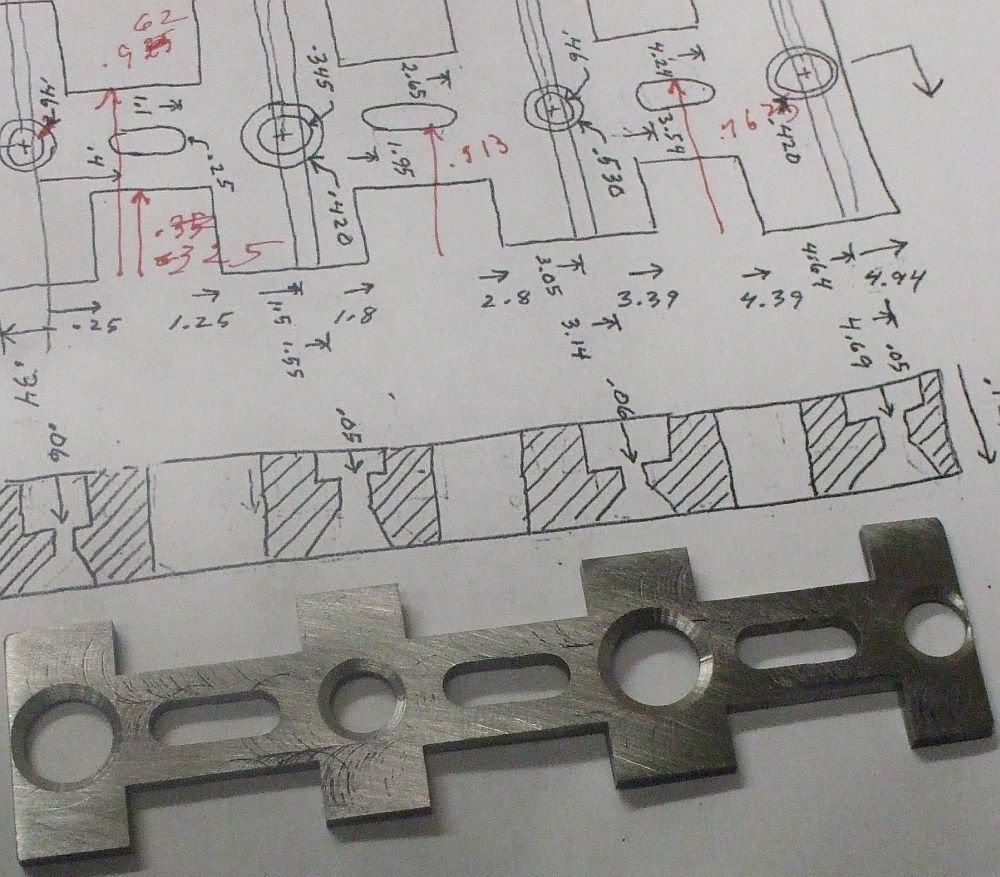

The second photo clearly shows the misalignment.

The third photo shows the case clamped in the jaws, ready to raise.

The fourth photo shows the case sitting on the shell plate, but not clamped.

Notice how the case tilts slightly to right in photo #3 from where it is photo #4.

I am new to reloading and this press, so any guidance or wisdom from others on how best to deal with this is welcome.

- Phil