I recently picked up a co ax press on here. I am about as happy as I can recall with a purchase! Having had rcbs,lee,redding and Dillion's. I have to say this must be one of the nicest presses I have found!! Any one on the fence JUMP!!

Ok on to my questions!

What do you use for lube on moving parts?

Has any one thought of drilling and installing zerk fittings??

What cartridges have you not been able to size or load on the co ax?

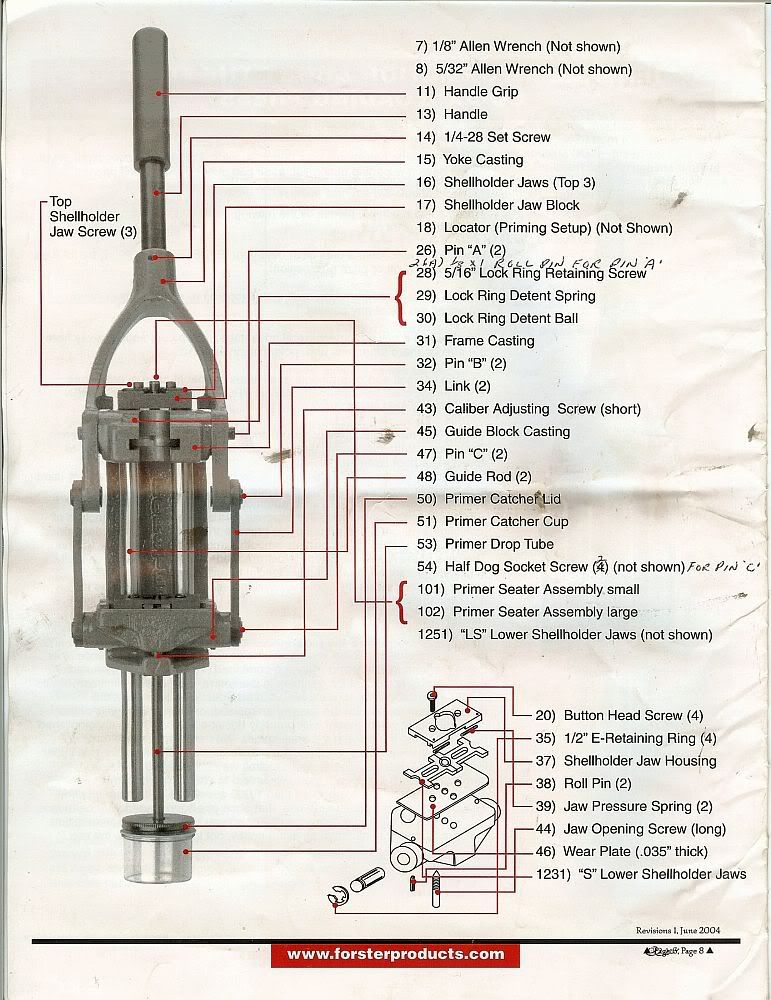

What sizes do the LS case holder jaws used for?

I would love to hear any tips or modifications for the co ax!

Ok on to my questions!

What do you use for lube on moving parts?

Has any one thought of drilling and installing zerk fittings??

What cartridges have you not been able to size or load on the co ax?

What sizes do the LS case holder jaws used for?

I would love to hear any tips or modifications for the co ax!

Last edited: