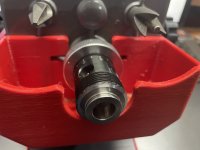

I've messed around with different case trimmers and really like the shoulder referenced setup. A Henderson trimmer costs an arm and a leg by the time you get it to Australia. I bought one of the Frankford Arsenal drill mounted cutters a while back and it worked great, it was just a bit fiddly with the plastic collets and washers and needed a separate chamfer tool. I was going to make a motor driven setup for the cutter and chamfer tools but then I saw the FA powered case trimmer for sale on Amazon for a good price and bought it. I made a few upgrades straight away. I machined the case holder setup to fit the "ugly trimmer" steel case specific pilots (that gets rid of the plastic collet and washer) and fitted a carbide cutter and inside chamfer tool to it. I've got pilots for pretty much everything I shoot and machined some blank ones for the oddball cases (6.5 SAUM and 223 Ackley).

I also designed and printed a chip catcher basket for it and replaced the little toolbox on top with a storage block for the pilots and different cutters. (The chip basket is on Thingiverse if anyone wants to print themself one).

This is actually a really good bit of gear now after a night's work machining bits and printing the parts. It's repeatable to within .001" or so and very quick.

I also designed and printed a chip catcher basket for it and replaced the little toolbox on top with a storage block for the pilots and different cutters. (The chip basket is on Thingiverse if anyone wants to print themself one).

This is actually a really good bit of gear now after a night's work machining bits and printing the parts. It's repeatable to within .001" or so and very quick.