Review of 5 total Nemesis Arms Vanquish & EDM Mini-Windrunner .308 Rifles

Ever since first setting eyes on the Nemesis rifle, I knew I had to have one. The ability to breakdown a sniper rifle and stow it easily into a small backpack seemed not only awesome but absolutely groundbreaking. The design appeared so simple, solid, and versatile. I watched the video of David Ives’ rooftop deployment a dozen of times. When I saw it in The Bourne Legacy, I wondered why I did not already own one.

I picked up five of these rifles within a few months of each other last year. Two were EDM and the other three Nemesis Arms. EDM Arms invented and produced the first 50x Mini-Windrunners before selling the design to David Ives of Nemesis Arms who later renamed it the Vaquish. Unfortunately due to life and work, I was not able to thoroughly test any of the rifles for several months and until I already owned and quiver full. At the time, there was very little information about the rifles online. From the scarce information I found online, I concluded they must be fairly good rifles. However after thoroughly testing them, I would not recommend this platform to anyone. I have written this review based on my personal experiences and testing of five Mini-Windrunner rifles. This is the review I wish I could have found and read myself before investing in these rifles.

All rifles tested (EDM and Nemesis Arms) fell below factory standards for entry level factory rifles in regard to accuracy, fit, and finish. The test targets were over 2 MOA, the fit and finish was hit or miss, and the customer service turned out incapable and downright rude. Based on my testing and experience with five of these rifles, I would not recommend Nemesis Arms to anyone.

2. TEST TARGETS

Analysis:

The Nemesis Rifles performed well below any factory rifle I have ever fired. The 2.18” Nemesis Arms group clearly illuminates a serious lack of accuracy. Here’'s some data for comparison from my personal experience:

My Patriot Arms Surgeon 308 shot under .40 MOA (MOA = minute of angle ~ 1” at 100 yrds) and my early Remington 5R shot around .50 MOA. My Tactical-Operations Tango-51 groups under .25 MOA. Benchresters shoot 6mm rifles averaging around .15 MOA, the world record bench rest group is .0077” at 100yrds. Military M4s shoot around 4 MOA and AK-47s much worse. The Army M24 groups at .50 MOA, the M110 1MOA+, the SR-25 was .50 to .75 MOA, and the M107 (semi-auto) 2MOA. $5000 Custom Tactical rifles are generally 0.50MOA and under. Factory heavy barrel $1000 Remington 700s shoot around .5-.75MOA; $400 Remington 700 hunting rifles at Walmart shoot .75-1.5 MOA. The Nemesis 2 MOA shot groups are clearly way below the industry standard for rifles.

EDM #013 shot better at 0.93 MOA. Note that this was after chamber measuring and after I pushed 14x rounds of FGMM (Federal Gold Medal Match 168 grain) back 0.02” specifically for this test. I seated the bullet lower with a reloading press.

Data:

This is one of the best and a very characteristic group of the 80x 168gr FGMM rounds fired from Nemesis Arms Mini-Windrunner #128. It almost looks like a group of 4x normal rounds and 6x flyers.

The Tac-Ops Tango 51 5x round group was fired only a few minutes later in exactly the same manner with the same 168gr FGMM.

Nemesis Arms Mini-Windrunner #057 shot slightly better, of the 20x total 168gr FGMM rounds fired from it. Note the chamber of this one also appeared better in my chamber measuring results.

The much older EDM Arms Mini-Windrunner outperformed the Nemesis Arms rifles. 20x rounds total 168gr FGMM were fired from this EDM.

3. CHAMBER MEASUREMENTS

Analysis:

The rifle chamber is one of the most important aspects of accuracy in a rifle, if not the most important. Chamber measurements, tolerances, and concentricity is the most influential/beneficial part of buying a custom rifles. Good gunsmiths adjust chambers to match specific bullets, shooter intents, barrel twists, and more. Often the specifics of the tolerances and finishing techniques are closely guarded shop secrets. On the other side, the first step in precision reloading is chamber measurement, which allows reloaders to custom load rounds specifically to fit best in the chamber. In contrast to custom gunsmith chambers, factory chambers are usually longer. This ensures any weight/length of bullet can be used safely in the chamber, but as a result normal rounds in factory rifles usually have much further to “jump” from the case neck to where the rifling lands begin. The chamber is one of the main contributors in the lower accuracy of factory rifles vs. custom rifles.

Both the EDM and Nemesis chambers were very short, although all fell within the SAAMI Specification. The chambers were “Palma Match” Chambers. Palma shooters fire 155 gr bullets with open sights. The barrels are generally very long with 1:13+ twist rates to suit the relatively light (and mandatory in the sport) 155 gr bullet. In contrast, long range .308 shooters use heavy 220 gr bullets to reduce wind effect. They use 1:8 to 1:10 barrels. Tactical .308 shooters are content with a compromise in the middle (usually mandatory government supplied) 168 or 175 gr BTHP. Their optimal twist is 1:11.25. The combination of a Palma chamber with a 1:10 barrel on a rifle intended for the tactical rifle is not one I have seen before, and for good reason as it strikes me as out of touch with shooter needs and technical competency.

The finish machining observed on the Nemesis Arms chambers appeared rough with notable imperfections not usually observed, even in cheaper factory rifles. The Nemesis Arms factory re-chamber measurements revealed rough machine work and little, if any, finish work. The poor accuracy performance of the Nemesis Arms rifles could be explained by the chamber data and observations below.

Data:

Nemesis #057: 2.192” +-.005 very sharp/abrupt angle to bore, easy to measure

Nemesis #128: 2.207” +-.005 very sharp/abrupt angle to bore, easy to measure

Nemesis #560: 2.285" +-.005 slightly more gradual, 360 ring contact w/6x lands showing at the same time

EDM Arms #013: 2.220” +-.005 abrupt angle to bore, slightly less sharp than older Nemesis

Patriot Arms 308: 2.230" +-.02 extremely gradual transition to bore

Tac-Ops 308: 2.288" +-.01 medium angle to bore, very even and smooth 4x lands

Rem 700 5R: 2.352" +-.01 very even marks

After Chamber Adjustment by Nemesis Arms:

Nemesis #57: 2.332” +-.005 very sharp/abrupt angle to bore, less even then before

Nemesis #128: 2.325” +-.005 two marks 180 degrees apart appeared sooner and marked much harder than the other 4. 7x marks showed during full contact (this is a 6 groove barrel)

Bullet OGLs:

FGMM Ammo: 2.210-2.223" (sample size 10x, same box)

SAAMI OGL spec for 308 Win 2.1835" (this was a hard spec to find... found on 6mmbr.com)

Twist Rates: EDM #013: 1:11”, All Nemesis: 1:10

4. OBSERVATIONS ON FIVE INDIVIDUAL RIFLES

EDM #047: (again, EDM designed and built the first 50x Mini-Windrunners before selling the design to David Ives of Nemesis Arms who took over production of the rifle)

At first glance the EDM didn’t look bad. The action felt fairly smooth. It appeared to only have been fired 50-200 rounds (based on little bolt finish wear and other mating surface wear). However, the stock deployment was pretty rough; it was not near what you would expect for the price. The trigger was excellent.

The stock on this rifle was "upgraded" by Nemesis Arms. They upgraded several of the older EDMs with their new stock with larger diameter rods and an aluminum (rather than cast pot metal) butt end. The machining of the lower receiver by Nemesis Arms pictured below is extremely rough.

The push button release appeared well cast. The teeth on the inside which lock out the stock were very worn/deformed looking (sorry no pic). The notches in the stock were not the correct distance to accommodate the two 1” separated teeth of the locking button mechanism. This lack of alignment caused it to collapse each time it was fired.

I am going to go out on a limb here to guess that a group of partially inebriated firearms enthusiasts probably raced each other to see how fast they could put it together. This was not observed in any of the other rifles to any degree whatsoever. It also really didn’t seem to affect the lock-up.

...continued in next post

- Preface/Summary

- Test Targets

- Chamber Measurements

- Observations on Five Individual Rifles

- Customer Service

- Methods and Discussion

Ever since first setting eyes on the Nemesis rifle, I knew I had to have one. The ability to breakdown a sniper rifle and stow it easily into a small backpack seemed not only awesome but absolutely groundbreaking. The design appeared so simple, solid, and versatile. I watched the video of David Ives’ rooftop deployment a dozen of times. When I saw it in The Bourne Legacy, I wondered why I did not already own one.

I picked up five of these rifles within a few months of each other last year. Two were EDM and the other three Nemesis Arms. EDM Arms invented and produced the first 50x Mini-Windrunners before selling the design to David Ives of Nemesis Arms who later renamed it the Vaquish. Unfortunately due to life and work, I was not able to thoroughly test any of the rifles for several months and until I already owned and quiver full. At the time, there was very little information about the rifles online. From the scarce information I found online, I concluded they must be fairly good rifles. However after thoroughly testing them, I would not recommend this platform to anyone. I have written this review based on my personal experiences and testing of five Mini-Windrunner rifles. This is the review I wish I could have found and read myself before investing in these rifles.

All rifles tested (EDM and Nemesis Arms) fell below factory standards for entry level factory rifles in regard to accuracy, fit, and finish. The test targets were over 2 MOA, the fit and finish was hit or miss, and the customer service turned out incapable and downright rude. Based on my testing and experience with five of these rifles, I would not recommend Nemesis Arms to anyone.

2. TEST TARGETS

Analysis:

The Nemesis Rifles performed well below any factory rifle I have ever fired. The 2.18” Nemesis Arms group clearly illuminates a serious lack of accuracy. Here’'s some data for comparison from my personal experience:

My Patriot Arms Surgeon 308 shot under .40 MOA (MOA = minute of angle ~ 1” at 100 yrds) and my early Remington 5R shot around .50 MOA. My Tactical-Operations Tango-51 groups under .25 MOA. Benchresters shoot 6mm rifles averaging around .15 MOA, the world record bench rest group is .0077” at 100yrds. Military M4s shoot around 4 MOA and AK-47s much worse. The Army M24 groups at .50 MOA, the M110 1MOA+, the SR-25 was .50 to .75 MOA, and the M107 (semi-auto) 2MOA. $5000 Custom Tactical rifles are generally 0.50MOA and under. Factory heavy barrel $1000 Remington 700s shoot around .5-.75MOA; $400 Remington 700 hunting rifles at Walmart shoot .75-1.5 MOA. The Nemesis 2 MOA shot groups are clearly way below the industry standard for rifles.

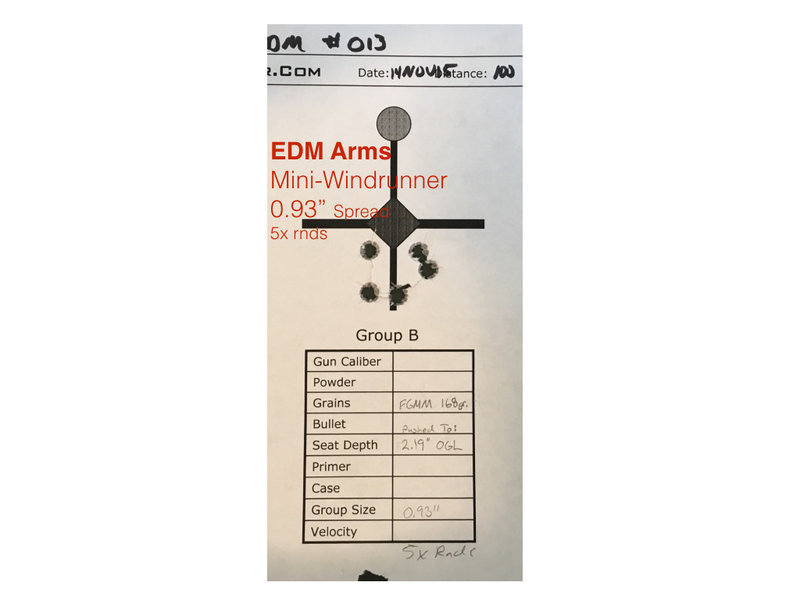

EDM #013 shot better at 0.93 MOA. Note that this was after chamber measuring and after I pushed 14x rounds of FGMM (Federal Gold Medal Match 168 grain) back 0.02” specifically for this test. I seated the bullet lower with a reloading press.

Data:

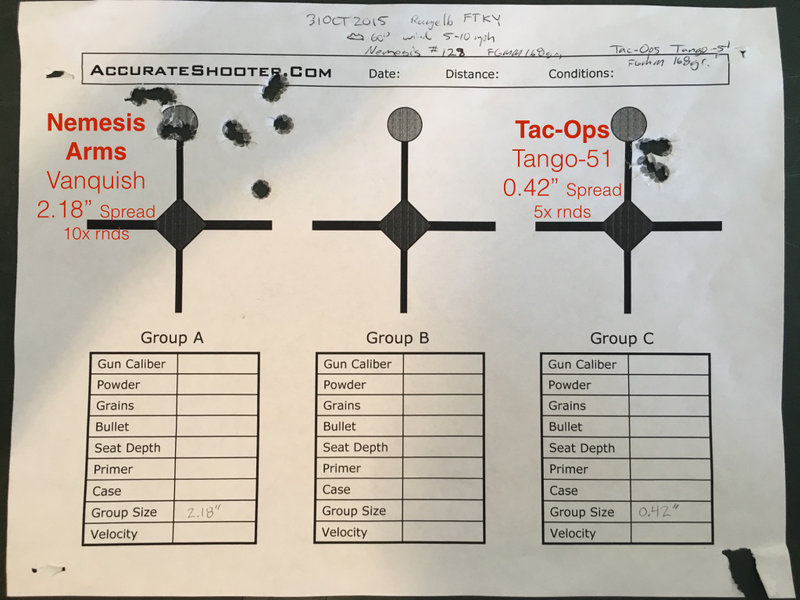

This is one of the best and a very characteristic group of the 80x 168gr FGMM rounds fired from Nemesis Arms Mini-Windrunner #128. It almost looks like a group of 4x normal rounds and 6x flyers.

The Tac-Ops Tango 51 5x round group was fired only a few minutes later in exactly the same manner with the same 168gr FGMM.

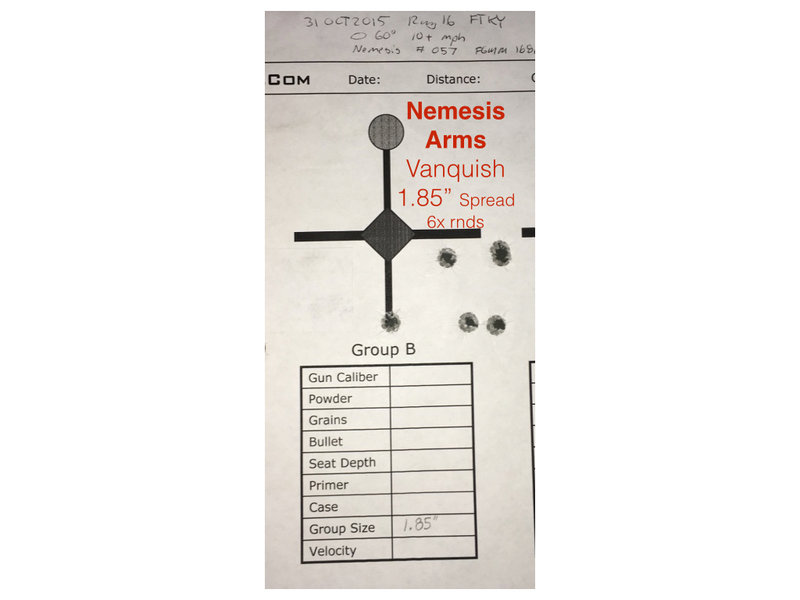

Nemesis Arms Mini-Windrunner #057 shot slightly better, of the 20x total 168gr FGMM rounds fired from it. Note the chamber of this one also appeared better in my chamber measuring results.

The much older EDM Arms Mini-Windrunner outperformed the Nemesis Arms rifles. 20x rounds total 168gr FGMM were fired from this EDM.

3. CHAMBER MEASUREMENTS

Analysis:

The rifle chamber is one of the most important aspects of accuracy in a rifle, if not the most important. Chamber measurements, tolerances, and concentricity is the most influential/beneficial part of buying a custom rifles. Good gunsmiths adjust chambers to match specific bullets, shooter intents, barrel twists, and more. Often the specifics of the tolerances and finishing techniques are closely guarded shop secrets. On the other side, the first step in precision reloading is chamber measurement, which allows reloaders to custom load rounds specifically to fit best in the chamber. In contrast to custom gunsmith chambers, factory chambers are usually longer. This ensures any weight/length of bullet can be used safely in the chamber, but as a result normal rounds in factory rifles usually have much further to “jump” from the case neck to where the rifling lands begin. The chamber is one of the main contributors in the lower accuracy of factory rifles vs. custom rifles.

Both the EDM and Nemesis chambers were very short, although all fell within the SAAMI Specification. The chambers were “Palma Match” Chambers. Palma shooters fire 155 gr bullets with open sights. The barrels are generally very long with 1:13+ twist rates to suit the relatively light (and mandatory in the sport) 155 gr bullet. In contrast, long range .308 shooters use heavy 220 gr bullets to reduce wind effect. They use 1:8 to 1:10 barrels. Tactical .308 shooters are content with a compromise in the middle (usually mandatory government supplied) 168 or 175 gr BTHP. Their optimal twist is 1:11.25. The combination of a Palma chamber with a 1:10 barrel on a rifle intended for the tactical rifle is not one I have seen before, and for good reason as it strikes me as out of touch with shooter needs and technical competency.

The finish machining observed on the Nemesis Arms chambers appeared rough with notable imperfections not usually observed, even in cheaper factory rifles. The Nemesis Arms factory re-chamber measurements revealed rough machine work and little, if any, finish work. The poor accuracy performance of the Nemesis Arms rifles could be explained by the chamber data and observations below.

Data:

Nemesis #057: 2.192” +-.005 very sharp/abrupt angle to bore, easy to measure

Nemesis #128: 2.207” +-.005 very sharp/abrupt angle to bore, easy to measure

Nemesis #560: 2.285" +-.005 slightly more gradual, 360 ring contact w/6x lands showing at the same time

EDM Arms #013: 2.220” +-.005 abrupt angle to bore, slightly less sharp than older Nemesis

Patriot Arms 308: 2.230" +-.02 extremely gradual transition to bore

Tac-Ops 308: 2.288" +-.01 medium angle to bore, very even and smooth 4x lands

Rem 700 5R: 2.352" +-.01 very even marks

After Chamber Adjustment by Nemesis Arms:

Nemesis #57: 2.332” +-.005 very sharp/abrupt angle to bore, less even then before

Nemesis #128: 2.325” +-.005 two marks 180 degrees apart appeared sooner and marked much harder than the other 4. 7x marks showed during full contact (this is a 6 groove barrel)

Bullet OGLs:

FGMM Ammo: 2.210-2.223" (sample size 10x, same box)

SAAMI OGL spec for 308 Win 2.1835" (this was a hard spec to find... found on 6mmbr.com)

Twist Rates: EDM #013: 1:11”, All Nemesis: 1:10

4. OBSERVATIONS ON FIVE INDIVIDUAL RIFLES

EDM #047: (again, EDM designed and built the first 50x Mini-Windrunners before selling the design to David Ives of Nemesis Arms who took over production of the rifle)

At first glance the EDM didn’t look bad. The action felt fairly smooth. It appeared to only have been fired 50-200 rounds (based on little bolt finish wear and other mating surface wear). However, the stock deployment was pretty rough; it was not near what you would expect for the price. The trigger was excellent.

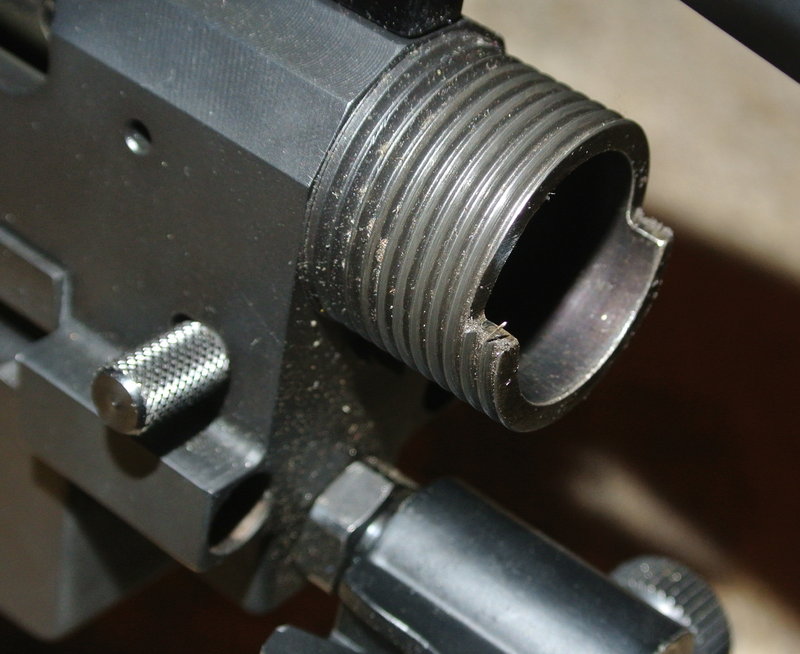

The stock on this rifle was "upgraded" by Nemesis Arms. They upgraded several of the older EDMs with their new stock with larger diameter rods and an aluminum (rather than cast pot metal) butt end. The machining of the lower receiver by Nemesis Arms pictured below is extremely rough.

The push button release appeared well cast. The teeth on the inside which lock out the stock were very worn/deformed looking (sorry no pic). The notches in the stock were not the correct distance to accommodate the two 1” separated teeth of the locking button mechanism. This lack of alignment caused it to collapse each time it was fired.

I am going to go out on a limb here to guess that a group of partially inebriated firearms enthusiasts probably raced each other to see how fast they could put it together. This was not observed in any of the other rifles to any degree whatsoever. It also really didn’t seem to affect the lock-up.

...continued in next post

Last edited: